In the recent past, solid wood was the main material for making furniture. Now, instead of natural wood, a laminated board, MDF, plastic, and various types of alloys are increasingly being used. Plywood should also be included in the list: this material is great for furniture production, so it does not lose popularity over the years.

- What is plywood

- Is it worth it to make furniture from plywood

- Plywood furniture in the interior

- Do it yourself furniture

- Material Processing - Methods

- Furniture assembly procedure

- Decorating plywood furniture

- Care for plywood furniture

What is plywood

Fiberboard or plywood is a multi-layer building material that is made by gluing wood veneers of coniferous or deciduous species. To increase strength, the thinnest sheets of wood are laid perpendicular to each other, and then glued under pressure using a press. Thus, plywood is a natural wood material, but contains glue (usually phenol-formaldehyde or urea-formaldehyde resin).

All plywood can be divided into construction (industrial) and decorative. Construction is highly durable, decorative has a more attractive appearance. Also, plywood is classified into the following types:

- FOF - moisture resistant material coated with a PVC film;

- FSF - plywood without lamination, but with high moisture resistance, suitable for outdoor furniture;

- FBA - sheets glued with natural adhesive;

- FC - a material based on birch veneer and formaldehyde resin;

- FBS is plywood that has undergone bakelite varnish processing and does not lose properties under the influence of moisture.

As for raw materials for the manufacture of plywood, it can be deciduous, coniferous or combined. As a deciduous base, wood of aspen, poplar, maple, alder, and birch is used. It is birch plywood that has the highest price and the most durable, it is most often used for the manufacture of furniture. Coniferous raw materials (pine, cedar, larch) are saturated with resins, so they better resist moisture and are suitable for furniture that will stand in humid rooms. In combined plywood, the outer layer is deciduous, the inner is coniferous. It is great for creating furnishings.

to contents ↑Is it worth it to make furniture from plywood

Some people believe that plywood is a weak material, the furniture of which will not last long. This opinion is erroneous. On sale you can find plywood of various thicknesses - from 1.6 mm to 7.6 cm. In the furniture industry, thin sheets (3-5 mm) of building material are used to make decorative elements and countersunk parts. Structural details are made of plywood up to 1-1.5 cm thick. Some brands of plywood are bendable: after soaking, a sheet of material can be bent and a blank can be made according to the existing template.

When selecting plywood sheets for our own production, it is important to consider that each type of material is considered environmentally friendly. Some types of plywood are suitable for outdoor use only. For example, FBA is considered the safest, and FBS is the most durable, but based on non-environmentally friendly components. When buying building materials, you need to pay attention to the country of the manufacturer.Usually a minimal amount of formaldehyde is found in Finnish plywood. A large proportion of harmful resins are often present in Chinese building materials.

Plywood furniture made from quality raw materials has a lot of advantages:

- simplicity in processing, restoration, repair;

- strength, reliability, long service life;

- resistance to damage, humidity, temperature fluctuations;

- the ability to create objects of any shape and design;

- low price (compared with wood)

- relevance in any room;

- preservation of a pleasant wood texture.

If the furniture is treated with varnish or other polymer coating, it will serve without problems even in the interior of the bathroom, it will not warp, it will not delaminate. The surface repels dirt, withstands movement, transportation, can be covered with any waxes, paints, stains. The disadvantages of plywood can only appear if it is improperly selected. For example, in the presence of harmful components, furniture will become a source of unpleasant odors, and sheets that are too thin can become deformed.

Plywood furniture in the interior

Beautiful and practical building material can become the basis for the manufacture of a variety of interior items. Plywood furniture is suitable for any room in the house:

- Hall, hallway, corridor. Laminated products are ideal for such spaces. They can brag of wear resistance, durability, simplicity of restoration. From plywood, you can make a frame for a mirror, a base for a pouffe and banquets, a stand for shoes, a cabinet.

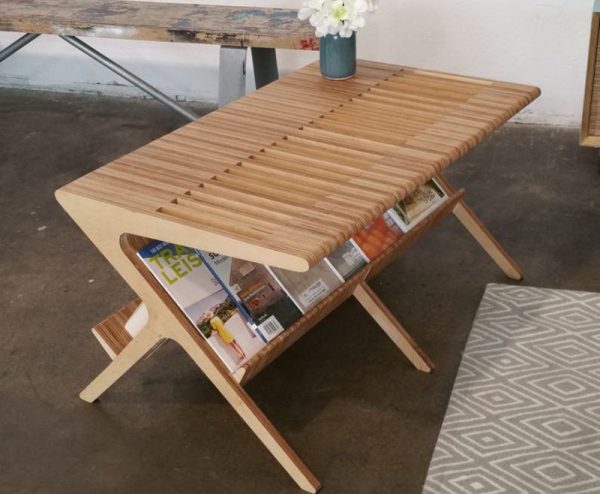

- Living room. In the room for receiving guests from plywood make shelves, racks, frames for tables, walls. Such products look especially good in living rooms, made in the styles of ethno, country, provence.

- Bedroom and nursery. When choosing an environmentally friendly building material, you can safely use it for the production of beds for adults and children, cabinets, chests of drawers, bedside tables, as well as chairs, tables. For a beautiful appearance, it is recommended to cover the furniture with a stain and varnish.

- Wet rooms. In the kitchen, in the bathroom should be installed furniture made of moisture-resistant material, which serves no worse than products made of chipboard and solid wood. In the kitchen, plywood, as a rule, is made only of the back walls and sides, although after processing with special compositions it will also serve to create facades.

to contents ↑Plywood furniture allows you to inexpensively furnish office space, catering establishments. This material makes high-quality tables and chairs, wardrobes, paper racks, shelves. The sheets impregnated with bakelite varnish can become the basis for garden products - tables, armchairs, chairs, sun loungers. Only for the winter period they will need to be brought into buildings, and the rest of the time they easily tolerate precipitation and temperature changes.

Do it yourself furniture

For the production of furniture, you need to follow the advice of professionals, have the necessary equipment and supplies. It is important to act carefully and without rush. If you do not exercise caution, there is a risk of plywood splitting, which can deteriorate from the wrong choice of tool or too much pressure. Sketches of parts are first drawn on paper, then transferred to plywood. To create paired elements, one of them is first cut out, then they are used as a template.

to contents ↑Material Processing - Methods

Cutting sheets in the manufacture of parts can be produced in various ways. Typically, the following tools are used for this purpose:

- Jigsaw. The simplest, cheapest, affordable device for working with plywood elements is a jigsaw, however, it is suitable only for small-sized products. It is important to choose the right blade, which is designed specifically for plywood. To ensure smooth cuts, draw a thin line with a pencil, then paste masking tape on the edges of the joint, only then make a jigsaw.

- Joiner's saw. A blade with 80 teeth or more is placed in such a tool, which will ensure a minimum gap.Also, for high-quality slices, a saw blade is used, having previously perfectly aligned the saw.

- A circular saw. As in the case of a carpentry saw, a blade with 80 teeth is selected for a circular tool, which will give a clean cut without chips and tears.

- Hand saw. This method of cutting will be the most difficult and time consuming. Slow, short cuts are made to ensure that there are no tears. Usually, round or curved parts are cut in this way.

Furniture assembly procedure

After performing the necessary measurements and cutting parts, as well as buying accessories, you can proceed to assembly. It is necessary to draw a plan of connecting the parts in advance, to think over the design of the future piece of furniture. It’s better to start with a small kitchen cabinet, chair or even a drawer to gain the necessary skills.

The side parts of the elements are processed with a grinder, the chamfer around the perimeter of the plywood sheets is milled. The parts are interconnected using metal furniture corners and self-tapping screws, fixed with clamps. All holes for screwing in self-tapping screws are pre-drilled, and only then are fasteners installed.

Decorating plywood furniture

If you wish, you can treat the furniture with a stain, varnish, change the paint or even perform a drawing. Preliminary, the product is carefully sanded, and if it is laminated, it is only degreased. After covering the parts with a primer on wood, dried and applied the selected finishing material. If necessary, for decoration use a self-adhesive film, stickers, decoupage. Only after the final processing is the hardware fastened - wheels, rollers, handles, awnings, etc.

to contents ↑

Care for plywood furniture

Plywood products are quite unpretentious. They do not require special conditions for normal use. To prevent dusty surfaces, they are regularly wiped with a damp, well-wrung cotton cloth. If necessary, the furniture is washed with a washing solution, which is then thoroughly washed and allowed to dry. To reduce dust accumulation, furniture is treated with an antistatic agent.

For products to last longer, you should follow these tips:

- maintain normal humidity in the room (about 60%) - this will prevent plywood from drying out;

- Do not place hot objects on furniture surfaces;

- periodically process products with polish or oil on wood.

Plywood furniture is a real find for those who value practicality and environmental friendliness in the environment. It will fit perfectly into the interior, will not cause unnecessary expenses and will allow you to admire the natural beauty for many years!