Windshields, despite their high strength and reliability, are considered a rather vulnerable point of the car. They often have to be changed after being hit by a stone or other trouble, which leads to the appearance of large cracks. Replacing glass is an expensive service, but you can do it yourself if you wish. It is only necessary to choose a good sealant for gluing car windows and to perform the work correctly.

- Purpose and main characteristics of sealants

- Varieties of car glue for glass

- For glass mounting

- To eliminate glass defects

- Types of automotive sealants

- Silicone

- Polyurethane

- Anaerobic

- Heat resistant

- Rules for choosing glue for glass repair

- Adhesive Adhesive Benefits

- Which sealant is better

- Sikatack drive

- 3M Windo Weld SuperFast Urethane

- Dow Automotive Betaseal 1527

- Dow corning 7091

- 3M PU 590

- Abro WS 904

- Donedeal DD6870

- "Efimastika RV"

- Teroson PU 8590

- Merbenit SK212

- Liqui Moly Liqui Fast 1400

- Instruction for use

- Sealant consumption calculation

- How to remove old sealant

Purpose and main characteristics of sealants

Glass sealants are used to install or repair glass, as well as headlights, decoration elements. They are used where it is impossible to attach the part in another way, while the finished seam will not be afraid of vibration, temperature extremes and contact with moisture. The main objective of the compositions is a solid connection of parts and sealing joints so that moisture and air do not penetrate into the interior. This is a prerequisite for a safe ride: when condensation occurs, the view of the road deteriorates greatly.

A good sealant for glasses is characterized by such properties and technical parameters:

- the time to complete the polymerization is 1-24 hours;

- the approximate period before the initial setting of the composition is from 15 minutes, to the formation of a strong film - up to 30 minutes;

- density - 102-1.35 g / cubic cm;

- operating temperature - from –40 to +90 degrees;

- shrinkage - no more than 1%;

- consistency - thick, pasty;

- elasticity - high;

- the possibility of applying to old sealant.

to contents ↑Using a suitable composition, you can independently glue the glass for a minimum period of time and start operating the machine on the same day.

Varieties of car glue for glass

As a glass adhesive sealant, not every composition from the first store is suitable. For example, ordinary superglues are not suitable for this purpose - they do not have the necessary degree of elasticity, so the seam will quickly deteriorate from regular vibration. To eliminate damage to the glass, you should also choose a special glue, which:

- will not cause a decrease in the transparency of glasses;

- eliminate the appearance of ugly spots;

- “Freezes” a crack, prevents its expansion and creep.

A good sealant for auto glass is able to combine vibrating bases, which, in addition, are constantly exposed to ultraviolet radiation, detergents, moisture, wind, temperature extremes. There are different types of glue selected by users depending on the problem encountered.

to contents ↑

For glass mounting

Compositions for gluing glass replaced obsolete rubber gaskets. Typically, such products are prepared on a polyurethane basis, so the design will be completely hermetic, while the seam will remain elastic. Safety for passengers is maximum - even in an accident the glass will not fly out.

Sealants can have another basis - other artificial resins, silicone (rubber). In any case, before buying, you need to make sure that they are suitable for working with glass, and also purchase a primer to enhance the adhesion of dissimilar surfaces and improve the protection of the joint from ultraviolet radiation. The conductivity of the sealant should be low or absent so that the owner of the machine is not affected by the appearance of static electricity.

to contents ↑To eliminate glass defects

Repair (optical) sealant is a car tool that allows you to seal a crack, close a chip on a windshield or other glass. After hardening, the seam formed by him repeats the structure of the base, so the sealant is almost imperceptible. The main properties of such a tool are listed below:

- high degree of transparency after polymerization;

- good fluidity, rapid penetration even into the smallest defects;

- resistance to moisture, ultraviolet radiation;

- lack of spots, darkening and yellowing over time.

to contents ↑Typically, auto glass repair sealants are sold complete with the necessary accessories - scotch tape, a blade, a needle to clean the crack from dirt, and a degreaser. Using such tools is not difficult, and repairs can be done with your own hands.

Types of automotive sealants

To avoid the penetration of dirt, water, air into the interior of the car, you need to buy only the highest quality sealant when pasting or repairing windows. Depending on the composition, there are different types of funds.

Silicone

Such products are based on artificial rubber (silicone), therefore they have high elasticity and are not afraid of vibration. After solidification, the sealants form a strong gasket like rubber. They reliably seal the windshield and other windows, and are also suitable for repairing windows and lights.

Most often, silicone sealants are used to seal cracks up to 4-6 mm deep. They are fluid, flowing, penetrate even the smallest gaps. The sealed seam can be heated up to +250 degrees without spoiling and reducing performance. The disadvantage of the compositions is their low resistance to the action of oils and alkalis.

Polyurethane

The adhesion to surfaces of such products is even higher than that of silicone sealants. They are made on the basis of polymers of the urethane group - resins of synthetic origin, due to which they have excellent elasticity, do not crack from vibration, and are not afraid of mechanical damage. Also, polyurethane sealants can boast of the following properties:

- resistance to moisture, ultraviolet, chemicals;

- lack of harm to metals (do not cause corrosion);

- quick cure;

- optimal consistency, sufficient fluidity;

- high tensile strength.

to contents ↑The disadvantage of a number of one-component polyurethane sealants can be called their maximum operating temperature - it is up to +100 degrees. Two-component formulations tolerate higher temperatures.

Anaerobic

Sealants that harden in an airless environment tend to retain ductility for a long time in air. This allows you to easily work with them even without the skills of gluing automotive windows. After curing, the anaerobic composition is transformed into a durable plastic-like substance that does not expand and does not dry out during operation, retains properties at temperatures ranging from –50 ... + 175 degrees.

to contents ↑Heat resistant

Such sealants are maximally resistant to high temperatures - they easily withstand heating up to +375 degrees. In addition, heat-resistant sealants do not deteriorate from the effects of vibration, stress, the effects of chemicals and ultraviolet radiation. Usually they are sold in the form of pastes, powders or aerosols.The first two options require the presence of a hardener (they are two-component) and before use they must be diluted in a certain proportion.

to contents ↑Rules for choosing glue for glass repair

If the composition is selected for automobile glasses, it should not just mask defects, but fill them, while at the same time "eating" into the surface. The sealant is required to show the best indicators of elasticity, cushioning ability and resistance to vibration. You should not choose products that dry literally in minutes - the longer the polymerization process lasts, the more reliable the finished seam will be. In addition, rapidly crystallizing compounds are difficult to operate, and it will be difficult to cope with them without the presence of dexterity.

To paste car glass, you need to choose a sealant of a higher density - too fluid compositions are inconvenient in operation and are more suitable for filling cracks. When buying material, you should also take into account the indicators of elasticity, resistance to mechanical stress and deformation, vibration and shear. High-quality sealant does not fade and does not turn yellow from the action of sunlight, does not deteriorate from moisture, direct and regular contact with water.

to contents ↑

Adhesive Adhesive Benefits

A good sealant is ideal for base materials (glass, plastic, metal), does not cause damage. He also has a number of other advantages:

- plasticity - under the influence of temperature extremes, the glass arrangement parameters can change, and the sealant easily adjusts to them, without losing integrity;

- elasticity - the seam absorbs part of the vibration and shock loads, smooths out sudden “jumps” of the car during driving, ensuring safety for the glass elements of the car;

- optimal curing speed - the owner does not have to wait several days to start using the machine again - usually the sealant lasts less than a day for complete polymerization;

- ease and convenience of work - if the instructions are strictly followed, even a novice master will be able to paste the glasses.

Which sealant is better

When choosing a product, it is worth paying attention not only to its parameters, but also to the brand's popularity: it is not recommended to buy the cheapest, unverified formulations.

Sikatack drive

A distinctive characteristic of the sealant is its suitability for any glass of trucks and cars. The product is produced in tubes of 310 ml, used without pre-heating at temperatures around + 20 ... + 22 degrees, freezes in 4 hours.

to contents ↑3M Windo Weld SuperFast Urethane

The sealant does not require the use of a primer, since it is quite durable itself and is not afraid of ultraviolet radiation. It can be used even on the windows of racing cars and cars, often driving on the road. After application, the product begins to set in 15 minutes, complete crystallization occurs in 8 hours.

to contents ↑Dow Automotive Betaseal 1527

A primer is included in the set of devices for performing a sealing joint - it is mandatory for use with this composition. The tool has the following properties:

- low electrical conductivity;

- initial setting in 12 minutes;

- highest strength;

- suitability for all types of transport;

- the possibility of applying at +5 degrees and above.

to contents ↑After gluing the glass, you can use the machine after an hour (in emergency situations), therefore, the tool is considered one of the fastest drying glass adhesives.

Dow corning 7091

This silicone-based compound is widely used when replacing glasses, because it has excellent adhesion to metal, plastic, is characterized by high elasticity, strength, and works at –55 ... + 185 degrees. Usually, white sealant is used for glass installation, although black and gray products are also on sale.

The composition of this brand is available in a standard tube of 310 ml, as well as in cans of 20 l and 250 kg (for industrial use). It hardens in 3 hours; when applied, it does not require priming, heating.

to contents ↑3M PU 590

The tool is considered universal, suitable for working with a variety of surfaces - glass, metal, wood, plastics. It sets in 25 minutes, dries completely in 4-8 hours, does not require the use of a primer. The disadvantages include the risk of cracks and crumbling when heated above +100 degrees.

to contents ↑Abro WS 904

A sealant under this name is highly regarded by professionals and is considered one of the leaders in the market. It is realized in the form of a tape twisted by a roll, easy to use, does not stick to hands, has a high degree of adhesion and plasticity.

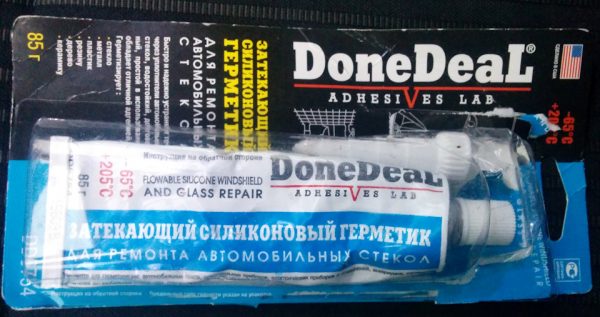

to contents ↑Donedeal DD6870

The tool has a high degree of transparency, imperceptibly on the glass, can be used to repair other parts of the car. The characteristics of the sealant are as follows:

- temperature during operation - from +5 to +30 degrees, temperature range during operation –45 ... + 105 degrees;

- connection strength - 195 kg / sq. cm;

- initial setting time - 1 hour, the period until complete polymerization - 24 hours.

The sealant is well suited for bonding materials with different coefficients of thermal expansion - plastic, glass, plexiglass, rubber, metal. It does not deteriorate from vibration, mechanical stress and the effects of chemicals.

to contents ↑"Efimastika RV"

One-component polyurethane sealant is used in conjunction with the primer that comes with the kit. It forms a very strong connection between glass and metal, plastic, completely freezes during the day, although it forms the initial film in 30 minutes. The seam can be operated at temperatures from –40 to +80 degrees, has a high tensile strength (6 MPa).

to contents ↑Teroson PU 8590

This sealant is also prepared on the basis of polyurethane; it is widely used for gluing auto-glass not only in cars, but also in trucks, buses, railway cars. Requires prior primer application. Grasps in half an hour, dries in 4-6 hours. It has UV resistance, wear-resistant, holds glass securely immediately after insertion.

to contents ↑Merbenit SK212

The tool based on modern MS-polymers boasts the highest tensile strength, it is used even in shipbuilding. The sealant does not need a primer, heating, it is resistant to vibration, stress, ultraviolet, protects the metal from corrosion, can be painted even in semi-solidified form.

to contents ↑Liqui Moly Liqui Fast 1400

Polyurethane sealant of this brand is used for gluing any car windows, cures in a short time under the action of moisture. It has good firmness, elasticity, strength.

to contents ↑Instruction for use

The room for working with glue-sealant should have a plus temperature (most manufacturers recommend that it does not drop below +5 degrees, optimally above +15 degrees). The car must be in a static state for an hour.

Before work, wear safety glasses, gloves. It is advisable to try self-bonding the windshield, and only then try to put the rear or side windows, which is much more difficult. The procedure is as follows:

- old glue is not removed, but cut it to a thickness of 2 mm with an even cut;

- if required by the manufacturer, the product is preheated;

- glue is applied to the surface using a mechanical pistol or air gun with a uniform strip without thickenings, tears;

- fix the glass with masking tape for the duration of solidification;

- lower the side windows in the car, leave it to dry.

to contents ↑Until the sealant is completely frozen, you can not slam the car doors, and also often open and close the gates of the room where it is located. Do not wash the car within 48 hours after gluing.

Sealant consumption calculation

Typically, 300 ml is enough for gluing the windshield of a passenger car; 600 ml of product may be required for jeeps or trucks. It is better for beginners to purchase a composition with a margin in case of erroneous actions.

How to remove old sealant

If you need to get rid of improperly applied or loose sealant, you can warm it with a building hairdryer. When heated, the material softens and is easily removed from the base. The remnants of the product are removed with a knife, but you must act carefully so as not to scratch the body. If necessary, dissolve the pieces of the product in diesel fuel or white spirit.

Work with automotive sealants is simple, it does not imply the presence of special knowledge. If necessary, you can buy a tool for gluing glasses and carry out all the actions yourself - then you can save, but not lose in quality!