When performing construction work, it is often necessary to seal joints, joints, cracks and various defects. Acrylic sealant can be used for this purpose. Such a tool perfectly adheres to most materials, lasts a long time and is harmless to humans.

- Characteristics and properties of sealant

- Technical Parameters of Acrylic Sealant

- Sealant composition

- Application area

- Differences between acrylic and silicone

- Types of sealants

- Non-moisture resistant

- Moisture resistant

- Frost resistant

- Color differences

- Pros and Cons of Sealants

- Sealant Selection

- Features of the use of acrylic sealants

- What is the best sealant for?

- Expense of funds

- Removing Traces

- Popular brands

Characteristics and properties of sealant

Acrylic sealant is a composition based on acrylic resins intended for sealing and waterproofing various joints and joints. Acrylic based sealant is ideal for beginners, because it is very easy to use, does not freeze for a long time, so the position of the seam can be fixed. The product is moderately elastic, able to adapt to vibration, after drying it can be plastered, painted.

Acrylic sealants are suitable for sealing cracks, various holes: they can simply be poured in and wait for drying. They behave remarkably indoors, coping with deformation against the background of changes in humidity and temperature. But outdoor conditions are not very favorable for such compounds: in the cold, ordinary sealants, in which there are no special frost-resistant additives, will become too hard and may crack.

to contents ↑Technical Parameters of Acrylic Sealant

Acrylic sealants have an important quality indicator: the ultimate elongation at maximum voltage. If the product is stretched and subjected to other effects in excess of this indicator, it will be irreversibly deformed. The larger the number, the more elastic the sealant will be. Typically, a rate of 10% or more is sufficient to consider the sealant to be of high quality and not too tough. With an elasticity of 11-12%, the composition can be used outdoors.

Other specifications of sealants:

- the possible width of the seam is 6–50 mm (with a width of more than 6 mm an additional sealing cord is used);

- the optimal thickness of the seam is ½ of its width;

- operating temperature - from –15 ... –20 to +70 degrees and more;

- the appearance time of the film on the seam surface is 15 minutes;

- sealant setting time with the surface - 1 hour;

- drying time - 24 hours at a humidity of 50%, temperature +23 degrees;

- frost resistance (for special compositions) - from 5 cycles of freezing and melting;

- the average gap is 550%.

Acrylic based sealants are packaged in tubes, buckets, small tubes, other containers. It is only possible to store funds in a packed form at room temperature for no more than 1 year.

to contents ↑Sealant composition

Up to 50–90% of the composition is represented by an aqueous dispersion of an acrylic copolymer (polymethyl methacrylate).After solidification, it turns into a strong plastic-like substance, so plasticizers are added to improve plasticity. Also, acrylic sealant may contain the following substances:

- defoamers;

- ammonia in the form of an aqueous solution;

- thickeners;

- fillers;

- antiseptics;

- Surfactant.

Application area

The sealants do not contain solvents or other toxic substances, which is why they are excellent for interior use. You can apply them even indoors without the use of personal protective equipment. Most often, acrylic sealants are used as sealants for joints between wooden logs, timber. They are also useful for filling joints between concrete, reinforced concrete structures, sealing areas of abutment of individual elements to the walls.

Acrylic composition can be used as an alternative to building glue, for example, when gluing ceiling skirting boards. It is useful for fastening fillets, baguettes, moldings and sealing joints between them and the surface. With the help of acrylic, you can stick the ceiling tile, in parallel, covering the appeared gaps.

Differences between acrylic and silicone

Between compositions based on silicone and acrylic there is a difference both in properties and in application features:

- After hardening, acrylic seams can be processed. They are easily painted in any color with acrylic, latex, other water-based paints. If necessary, individual seams can be restored, local update. Paint does not fall on silicone or quickly peels off.

- Acrylic sealant can be machined: grind, drill. Silicone under such exposure is able to completely separate with damage to the connection.

- The moisture resistance of acrylic is an order of magnitude worse than that of silicone. The basis of acrylic sealants is an aqueous dispersion of acrylates, so they are still subject to dissolution. Silicone is a waterproof material like rubber.

- In terms of elasticity, acrylic is also inferior to silicone. Silicone sealants are more plastic, give less shrinkage, stretch to a greater distance without damage.

- Acrylic is vapor permeable, silicone is airtight. Due to this property, acrylic compositions do not violate the microclimate in the room, do not cause accumulation of steam, moisture.

- Acrylates have excellent adhesion to porous building materials and are best suited to wood, concrete. Smooth substrates before sealing should be treated with sandpaper or in another way to improve adhesion.

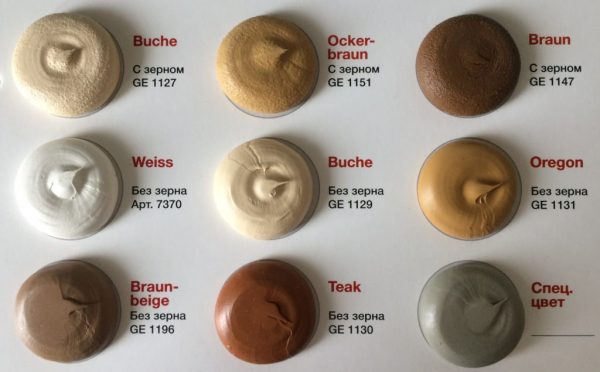

- The color scheme of acrylic compositions is much richer. If desired, you can choose a suitable tool of any shade, including for different types of wood. Silicone products are available in a limited range (usually in white, black, gray, red).

- The durability of silicone is very high - it lasts up to 20 years. Acrylic begins to deteriorate earlier, as it may dry out over time.

- The price of acrylic products is always lower than the cost of silicone. On average, the difference is 30-50%, which can be important for many users.

- Ecological acrylic is not in doubt. Such products are completely safe for humans and the environment. Acid-based silicone sealants emit an unpleasant odor, so you can not always use them.

Acrylic compounds are excellent for indoor use if the room does not have constant contact with water and too high humidity. Such funds are indispensable if the seam in the future must be painted.Most often, they are applied to cracks in window frames, seal doorways, plumbing. Silicone sealants are suitable for bathroom and outdoor use, can seal the walls of aquariums and other objects that come in contact with water. However, acidic silicone sealants can not be used on metal, concrete, natural stone, and acrylic in these cases will be suitable.

to contents ↑Types of sealants

All acrylate sealants can be divided into three groups. Differentiation is due to the introduction of various additives, the features of operation.

Non-moisture resistant

Such formulations are suitable exclusively for indoor use under conditions of low or normal humidity. They are ideal for gluing skirting boards, baguettes, minor repairs, construction works. They are best suited for concrete, brick, wood, and gypsum bases.

Moisture resistant

These sealants can have a combined composition (with the addition of silicone, rubber) or contain other improving components. Well suited for bathrooms and kitchens where humidity levels are elevated. Among other things, moisture resistant compounds better tolerate temperature changes, have high adhesion to building materials. They are more reliable than standard acrylic sealants bonded with ceramics, foam concrete, plastic, and some even with metal.

Frost resistant

Compounds from this group are resistant to aggressive environments, low temperatures, precipitation. They have an increased level of elasticity, so they do not crack from freezing. Usually, the minimum possible operating temperature of the products is –20 degrees, but there are also more frost-resistant sealants. They can close the seams between the logs, concrete slabs, apply a warm seam in the technology.

Color differences

Most often on sale you can find white or colorless products. They are very popular, as they are well suited to plumbing, sinks, tiles, and transparent compositions are hardly noticeable on surfaces. If you want to choose a sealant in the color of the base, you can purchase a pigmented composition: red, blue, green, etc. On sale there are products in the color of a tree: mahogany, cherry, wenge, oak and others.

Pros and Cons of Sealants

The use of acrylic in plumbing, construction and repair work has many advantages. The main advantages of such sealants:

- low cost;

- huge selection;

- easy application;

- the possibility of correcting flaws, washing off excess;

- lack of spots after cutting or rubbing drops of the product;

- non-toxicity, environmental friendliness;

- fire safety, incombustibility;

- the ability to work without personal protective equipment;

- good adhesion with many materials;

- carrying out painting, filling and machining of the seam, if required by the user;

- vapor permeability, lack of accumulation of condensate in the joints;

- resistance to UV study;

- lack of yellowing, darkening of seams with time;

- the possibility of restoration of a separate sealed area.

to contents ↑Among the shortcomings of the sealant is the poor tolerance of frequent contact with water. When exposed to a humid environment, acrylates dissolve sooner or later, the seam deteriorates. If the package is marked “moisture resistant”, then this composition may come into contact with moisture after the seam has completely dried.But even with such products, their properties will deteriorate over time if they often have to undergo exposure to water.

Sealant Selection

On sale you can find sealants marked "for windows", "for doors" or "universal". In fact, the difference between them is small. If the composition is purchased to work with smooth surfaces, you need to take a number of additional measures: apply a special primer with abrasive particles or treat the surface with sandpaper. Typically, such methods are applied to PVC, polycarbonate or other types of plastic.

When buying products for the bathroom, kitchen, you need to pay attention to the level of its moisture resistance, as well as the presence of fungicides in the composition. If you intend to seal the stove, fireplace, other heated bases, it is better to take a silicone or silicate composition with high heat resistance. To seal the joints of the aquariums, neutral silicone sealant is suitable, and acrylic will quickly collapse. To finish the shower, it is also worth choosing silicone, while acrylic is ideal for sealing windows: after drying, it can be painted.

Features of the use of acrylic sealants

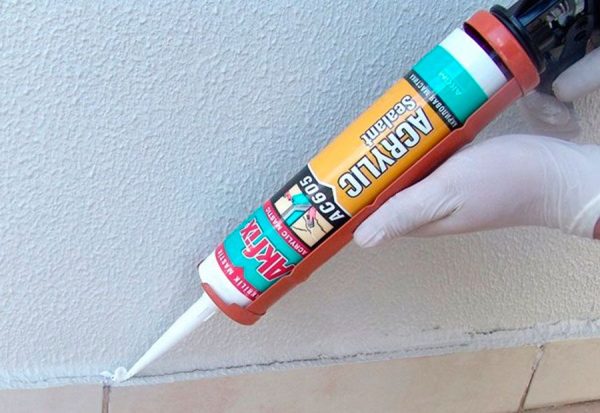

To apply the material does not require special knowledge or tools. It is only important to carefully prepare the base: clean from grease, dirt, peeling coatings, then dry well. If the seam is thick and wide, it is worth purchasing a sealing polyethylene cord in advance or filling the joint with another sealant. This will make the connection more reliable, reduce thermal conductivity and reduce the consumption of sealant by 40–70%.

Acrylic can be applied even without gloves, as it does not irritate the skin of the hands. Diluting it with water or any solvent is strongly discouraged - this will reduce the quality and cause rapid cracking of the seam. For application, you can use a special gun into which cartridges and tubes are conveniently inserted. Sealant from a jar, a bucket is better to spread with a small spatula, from a tube - just squeeze out, directing a thin nose to the right place.

After application, the product can be given any shape within 10-15 minutes. Then a polymer film begins to form, and repairing the seam will be difficult and inappropriate. The curing of the sealant lasts 24 hours, but at low temperatures the process can drag on for 2 days.

To increase the efficiency of work, it is worth considering the advice of professionals:

- if the sealing is carried out in the bathroom, you must wait at least 24 hours before using the surface, otherwise the top layer of the seam will blur;

- do not touch the joint until completely dry: the surface film may be damaged;

- humidity and temperature cannot be changed in the room until the polymerization of the sealant is completed;

- after opening the package, you will have to use the whole composition, otherwise it may lose its basic properties during storage.

What is the best sealant for?

Acrylic is suitable for various work in everyday life, at a construction site, in repair, but it is optimal to apply it to sedentary or fixed joints that do not regularly come into contact with moisture. Examples of work with this composition:

- cracked furniture repair;

- restoration of parquet, laminate;

- gluing linoleum;

- installation and repair of doors, windows, balcony blocks;

- installation of baseboards, baguettes;

- sealing tile joints.

Expense of funds

To calculate the required amount of sealant, you need to know the dimensions of the future seam. You can multiply the depth of the seam by its width, in the end, get an approximate amount of the product by one meter in grams.If the joint is triangular rather than square, the final figure is divided in half. On average, 250 g of sealant is enough for 10 meters of not too thick seams.

Removing Traces

It happens that the product falls on various surfaces in the house. Removing it until it solidifies does not amount to: just wash the base thoroughly with soap and water. If the composition has hardened, you can use a sharp knife or razor. Remove the product in layers, cutting it carefully so as not to damage the product. The remains are wiped with fine sandpaper, a metal washcloth or pumice. With delicate surfaces, sealant is cleaned with a wooden scraper. After work is completed, the item is washed with soap and other detergent and dried.

Popular brands

In stores, there are various sealants, the most popular are the following compounds:

- "Universal" from "Novbytkhim." Inexpensive product based on acrylate dispersion and mineral filler. After drying, it forms a moisture-resistant rubber-like seam of white color, which does not turn yellow over time. The sealant is non-toxic, withstands temperatures of -30 ... + 70 degrees. Designed for repair work inside and out.

- Zigger Acryl. Plastic, elastic means for sealing different substrates. Includes a freezing point additive. It has thixotropy, can be applied on vertical bases and ceiling.

- "Moment Acrylic Universal." It is used for hardening and sealing cracks, crevices in windows, for sealing joints of plumbing and floor, walls. It can be applied to the junction of metal sinks and walls, countertops in the kitchen. It retains properties at temperatures of –50 ... + 150 degrees, is neutral with respect to alkalis, oils, and remains strong for several years.

- Belinka Beldom Acryl. Acrylic sealant suitable for all building materials. It is quite elastic, withstands deformations within 5–10%. It does not wear out, it is resistant to sunlight, weathering.

- Loctite PL-S50. Universal frost-resistant composition based on acrylic water dispersion. Designed for hardening sedentary joints between concrete, brick, wood, gypsum, ceramics. Ideal for grouting cracked surfaces. Suitable for painting and plastering.

- Makroflex FA. Frost and thaw resistant sealant. Suitable for outdoor and indoor use. The seam is allowed to be painted one hour after drying. It can be used for all types of joints with slight deformation and tension.

- PENOSIL Premium Acrylic Sealant. Universal water-based acrylic composition, used to fill joints and cracks in sedentary joints. It is odorless, easy to apply, after drying it is subject to grinding and coating with paint and varnish. It is quite moisture resistant, can easily withstand contact with water after 5 hours after application.

In construction stores, there are other acrylic based sealants: Titanium, Crassus, Master Tex, Pufas, Kim Tech and others. Do not save and buy the cheapest composition. Products of famous brands have consistently high quality and are highly efficient. Working with acrylic sealants is simple and convenient, they will become reliable assistants in the home and at the construction site.