Electromechanics often use insulating sealant or compound in their work. Such compositions help to make high-quality insulation of wiring and various components, they look like varnishes, but they differ greatly in their properties.

- Description and types of compounds

- Epoxy

- Polymer

- Characteristics and use of silicone-based compounds

- DowDuPont Molykote Compound

- Other silicone compounds

Description and types of compounds

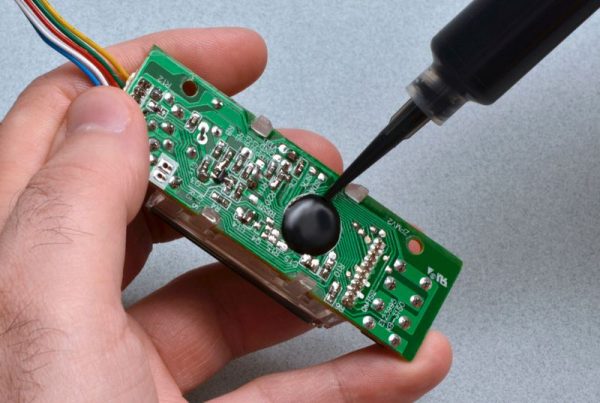

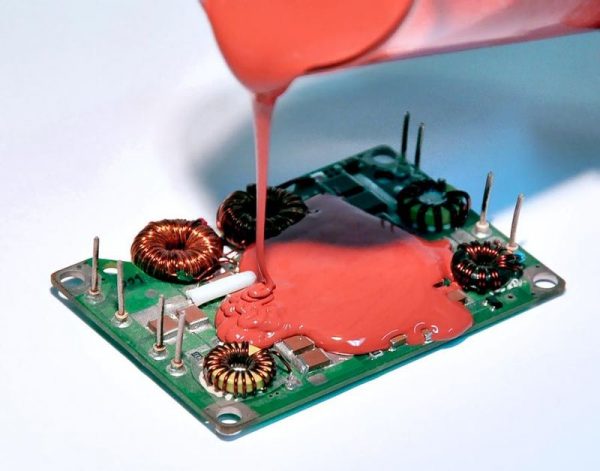

This is a dielectric material with a liquid or pasty texture, which is used to impregnate and fill microcircuits, radio components, wires, structures and components of various electrical devices.

After solidification and complete drying, a high-quality compound will have a number of properties:

- resistance to high temperatures;

- resistance to the influence of oils, greases, other chemicals;

- lack of damage from vibration, mechanical impact.

All electrical insulating sealants can be divided into impregnating and filling. The former are used to impregnate the windings of various units, motors. The second ones are intended for filling the space between the coupling and the cable, for sealing devices.

In addition, the compounds are divided into:

- thermosetting - after polymerization always remain solid;

- thermoplastic - under the influence of heat soften again.

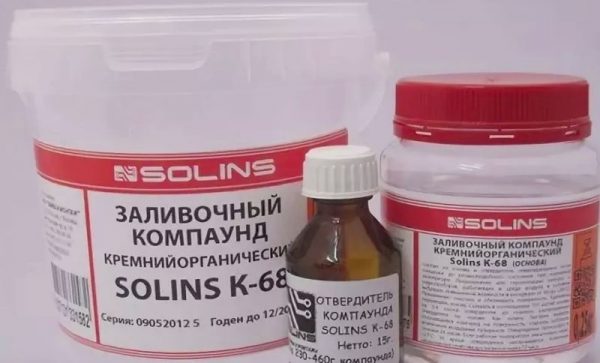

Compounds are differentiated into single-component, two-component, depending on the form of release. They are also subdivided into epoxy, polymer.

to contents ↑Epoxy

In the production of such sealants, modified epoxides are used - substances based on epoxy resin. They are characterized by low volumetric shrinkage (not more than 0.2-0.8%), high strength and chemical resistance. They are implemented in two-component form and may contain hardener and epoxy resin in its pure form or with the addition of fillers (usually quartz).

All epoxy sealants with electrical insulation properties are divided into two groups:

- Hot cure (cure with heat). Usually used as an impregnating agent. They have excellent heat resistance (up to +130 degrees), can withstand thermal shocks up to + 140 ... + 180 degrees. Sealants are frost-resistant (up to –60 degrees), arc-resistant (up to 200 seconds), are not afraid of contact with moisture, and seriously increase the strength of parts and windings. Most of these compounds are flame retardant and non-toxic.

- Cold curing (solidify without heating). Used for electrical insulation of wiring, connections and various devices, many are suitable for impregnation of the winding. They perfectly absorb vibration and are not destroyed by mechanical stress. Heat resistance can reach +180 degrees (depending on the particular brand of compound). Provide electrical strength from 20 kV / mm.

The disadvantage of most epoxy compounds is their short life after combining the components, then they become viscous and unusable.

to contents ↑

Polymer

These include all composite materials based on polymers (polyester resins, polyurethane, rubber, etc.). Such funds have a lot of positive properties:

- oil and petrol resistance;

- tolerance of the action of acids and alkalis;

- high strength;

- resistance to abrasion, other mechanical stress;

- the ability to operate in high humidity;

- lack of reproduction of mold, germs;

- sufficient adhesion to metals, alloys, fiberglass, plastic, textolite.

Polymer compounds are used to create a durable coating for wiring diagrams and circuit boards, are used to seal the wires, impregnate the winding.

to contents ↑Characteristics and use of silicone-based compounds

Silicone sealants are designed to protect items of radio engineering and electronics, which are exposed to high humidity at temperatures of –60 ... + 300 degrees. They boast a high degree of adhesion to most known materials, even smooth ones (after preliminary grinding), and are well suited for products made of ferrites and permalloys.

Silicone is characterized by optimal dielectric performance, resistance to ultraviolet, ozone resistance. Sealants based on it can be transparent or optically transparent, flame retardant, thermally conductive.

Some products contain additives to improve frost resistance, so they can be used in environmental conditions. Partial electrical conductive silicone sealants are also on sale, the purpose of which is to relieve static stress.

to contents ↑DowDuPont Molykote Compound

This sealant rightfully occupies a leading position among electrical insulating compounds. Molykote 111 has high dielectric properties, protects and seals products, has anti-corrosion ability, therefore it can be used on any metals and alloys.

The compound is compatible with most plastics and rubbers, is not washed with water, is not afraid of high humidity, low and high temperatures, as well as temperature shocks and extremes. Its only negative is the high price.

to contents ↑Other silicone compounds

Among electrical insulating sealants, EFELE grease for electrical contacts is no less popular. It can be applied to any one-piece and detachable electrical joints, terminal connections. Due to its perfect compatibility with plastic, the product is suitable for sealing sensors, relays, sockets, plugs, and batteries.

The main properties of EFELE are as follows:

- temperature tolerance within –40 ... + 160 degrees;

- water resistance;

- anticorrosive ability;

- resistance to the influence of acids, alkalis;

- density, excellent retention at the place of application;

- long term of operation;

- fire safety;

- lack of toxic and irritating effects on the body;

- convenient form and reasonable price.

Another popular electrical insulating sealant is Liqui Moly Electronic Spray, a synthetic aerosol lubricant. It is used to prevent the appearance of oxides and corrosion elements on automobile electrical equipment, to improve functioning and increase the service life of parts.

The tool is well suited for:

- plug connectors;

- starter;

- generator;

- antennas;

- breaker;

- relay etc.

Aerosol is completely safe for rubber, plastic, metal, varnished coatings. He is not afraid of moisture, temperature extremes. If necessary, Liqui Moly Electronic Spray can also be used to repair household appliances.

Proper use of compounds can improve the safety of operation of electrical components and devices. Applying a sealant protects a person from electric shock, and equipment from spoilage, moreover, really increases the service life of products.