An electric spray gun is an apparatus for painting a surface by spraying a dye. Paint from the device is released under the pressure of the built-in pump.

- Advantages of electrical devices

- Principle of operation

- Electrostatic painting

- Tips for choosing a spray gun

- Use and care

The market offers many different modifications of electric spray guns that differ from each other not only in technical parameters, but also in cost. In this article, we will review the main technical nuances of electric devices, the knowledge of which will help to choose the most suitable version of the spray gun.

to contents ↑Advantages of electrical devices

Electric models have a number of advantages:

- Mobility. The spray gun can be moved around the construction site, and there is no need for a heavy compressor or air pump - it is enough to have access to electricity.

- Ease of use and design. Devices intended for domestic use are distinguished by a simple design, which even a specialist can not figure out.

- Low weight and small size. Although the spray guns are small in size, up to a liter of paintwork is placed in the tank. Together with the tank, the total weight of the spray gun can be from 1.5 to 2.2 kilograms. Due to the low weight, comfort in work is achieved, as the hands will not be too tired.

- Economy of paint consumption. A moderately thin layer of material is fed to the surface, which distinguishes spray guns from rollers and brushes.

- Low cost device. Compared to pneumatic models, electric ones cost much less.

to contents ↑Note! Electrical modifications are not suitable for painting cars with liquid rubber.

Principle of operation

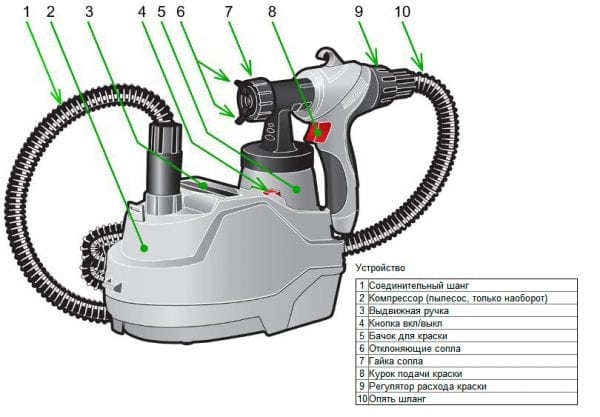

An electric spray gun operates by converting electricity into pneumatic energy. The paint under the influence of high pressure is directed from the tank to the spray gun, which distributes it on the surface.

The container for the paintwork is located either above the device (drain) or below it (suction). As a result of pressing the lever, the airbrush passes compressed air through itself. If you press harder, then the needle will shift, and the flow of paint will be reduced. In other words, the higher the air pressure, the less intensely the paint material leaves the spray gun.

For different consistencies of paint, there are separate types of spray guns. For example, devices with a larger outlet are used for thick paints than for liquid ones. The amount of ink entering is controlled by the so-called spray torch. The indicator of working pressure also depends on the type of paint material. Air supply regulation is carried out thanks to a special screw.

Any spray gun is equipped with a so-called gun. This device using a nozzle forms a torch as a result of mixing the following components:

- High pressure air that is supplied from the compressor.

- Working composition (varnish, primer or paint) corresponding to the acceptable viscosity parameters.

In the interior of the gun, the air is divided into two streams, one of which is directed in the center, and the second - on the periphery. All electro-sprayers are equipped with three controllers that allow you to set the desired operating mode:

- Adjusting the total air supply makes it possible to maintain a balance between the volume of paint supply and its application form at a certain speed mode. If the estimated paint consumption is low, the faucet is covered. After that, the feed rate will decrease, and the paint will be sprayed more accurately.

- The pressure on the side jets at the periphery is controlled by a separate screw. The air flow determines the shape of the stream of paintwork: the stronger the air supply, the wider the perimeter. If you stop the pressure on the side jets, the feed shape will become rounded. However, this is an extreme option, since in this case the hiding power of the paint will increase significantly, which will lead to drips.

- The flow rate of the paint material is determined by the volume of air supplied to the center of the electro-spray. To make the feed less plentiful, slightly cover the faucet.

Faucets can be in different places, depending on the modification of the device, however, two schemes are most common:

- The paint adjusting tap is located on the side of the gun. A little lower is the tap of the general air supply.

- A common air supply tap is located at the end of the handle, near the inlet pipe. The faucet that controls the width of the jet is located in the same place as in the first case - on the side of the gun.

Paint containers can be not only of different sizes, but also often installed in various places. Usually they take their place in the area of the front of the barrel, which improves the absorption parameter. There are two ways to supply the paint material:

- By gravity. In this case, the composition rushes down under the pressure of its mass. It is difficult to control the flow in this case, since it entirely depends on the diameter of the outlet from the tank.

- The more common use of the rarefaction effect. With this effect, a rapidly moving air stream forms negative pressure under the paint tank, as a result of which the composition is sucked.

to contents ↑Note! The main difference between an electric spray gun and a pneumatic one is the presence of an integrated compressor. The advantage of such a device is the impossibility of compressor overload.

Electrostatic painting

We should also say about electrostatic staining method surface. In the process, the paintwork, in contact with the electrode installed in the spray gun, receives a negative discharge (up to 100 kW). After spraying the paint, its particles along the force field rush exclusively to the painted structure. The advantages of the technology are obvious: reduced paint consumption and more accurate spraying.

to contents ↑Tips for choosing a spray gun

Before choosing an electric spray gun in the store, it is recommended to decide on the following parameters:

- The width of the torch. One of the factors when choosing a spray gun is the size of the area to be stained. If the stream is thin, it will take a lot of time to work. If the torch is wide, the consumption of paintwork may be too large.

- Nozzle size. For metallic coatings, a size of 1.2-1.3 millimeters is recommended, for acrylics and varnish - 1.4-1.5 millimeters, for soils - 1.5-1.7 millimeters, for putties - 1, 7 mm or more. There are interchangeable nozzle kits with a wide variety of sizes for sale.

- Nozzle cap. Stainless steel caps are recommended.

- Tank material. The metal tank is easier to wash after the end of work, however, such tanks are opaque, and therefore control over the consumption of material is complicated. A plastic tank is characterized by opposite qualities.

- The material from which the housing is made. The best option is high-quality plastic. It is lightweight and durable.

- Place of installation of the tank. The upper location of the container is preferable, as this will simplify the work with viscous compositions.

- The ability to control the process. Most devices have the minimum required number of adjustments. First of all, we are talking about controlling paint consumption. However, modern devices are equipped with adjustable working pressure, electronic control of the flow rate of the paintwork composition, different spraying options, etc.

- Ability to autonomous functioning. Some modifications can work without a battery, which makes it possible to work even where there is no access to the electric network.

Use and care

First of all, you need to deal with the type of paint that will be refilled with a spray gun. It’s impossible to simply fill in the composition from the can, as the device simply cannot cope with its spraying. We need a paint of a certain viscosity, which can be obtained only by dilution. To facilitate this task, almost all modifications are equipped with a special thicket, due to which it is possible to establish the density of the composition, based on the speed of its outflow.

The next important nuance is the choice of nozzles. Usually spray guns are equipped with several types of nozzles. The spray quality directly depends on the selected nozzle. The more viscous the composition, the larger the nozzle required. For alkyd mixtures and nitro enamels, a nozzle with a 0.6 mm hole is required, but for alkyd dispersions, a nozzle with a 0.8 mm hole is needed.

When applying paint, you should pay attention to the following circumstances:

- The normal distance from the spray nozzle to the surface is 10-15 centimeters. Too close a nozzle location will cause leaks, and too distant will cause paint to escape.

- The nature of the movements should be uniform, without jerking. Also, the uniformity of staining is influenced by the speed of surface treatment. Application of paint is carried out from side to side and down. If you move upwards, drips are inevitable.

- When painting, the jet should be directed exclusively perpendicular to the surface to be treated.

At the end of the work, the spray gun must be cleaned of residues of the paintwork composition. To clean the device, you need to dismantle the paint tank and drain the rest of the coloring matter from it. Next, pour solvent into the container.

For a couple of minutes, the liquid in the tank shakes, after which it is discharged into waste. Next, you need to again pour the solvent into the container and spray it with a spray gun. This is necessary to clean the internal channels of the device. Particularly thoroughly need to clean the nozzle - it is recommended to wipe it with a sponge soaked in a solvent.

The electro-spray is an excellent solution for domestic purposes, however, it is not suitable for professional surface painting. Pneumatic devices are characterized by better spraying of paints and varnishes, which directly affects the result of work.

It is also worth noting that electric sprayers are notable for their low power and are primarily intended for working with water-based paints. Therefore, before buying an electric spray gun, you should decide on the tasks for which it will be used.