Spraying with a spray gun is convenient, quick and, thanks to the relatively low consumption of dye, economical. But it happens that the painting with the help of a spray gun turns out to be uneven, streaks occur or poorly stained areas remain. This happens if the paint supply pressure fluctuates during the process of painting the surface. This can be avoided using pressure gauges for the spray gun.

- What is affected by the correct adjustment of the air mixture

- Types of pressure gauges

- Features spray gun settings

- Some subtleties of the adjustment process

- Difficulties in adjusting the device

What is affected by the correct adjustment of the air mixture

To get a beautiful product when using the hardware method of spray painting, it should be borne in mind that the quality of spray painting depends on:

- nozzle diameter;

- constant air supply pressure. This parameter is relevant only for pneumatic and electronic units.

The nozzle diameter for high-quality uniform staining should be constant (when it is changed, minor repairs are carried out to regulate or replace the part that has become unusable), and the air supply pressure varies depending on the paintwork material and the base material for painting. With increasing air pressure:

- Increased productivity. In a short time, you can paint a large surface.

- The dye deposition layer is reduced, but the stained area is greatly increased. Sometimes this requires re-applying layers to improve the quality of work and increase the protective properties of the coloring material (for example, when processing products exposed to aggressive environmental influences).

- Efficiency and quality of work are increased (paint consumption is reduced, which lays down in an even layer, without leaving streaks or stains).

- Work becomes more convenient. At low pressure, the dye has to stand close to the wall, making many unnecessary movements, while at high spraying is carried out from a relatively large distance.

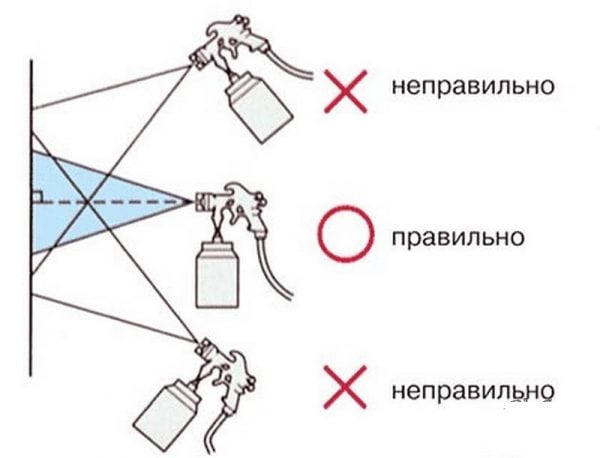

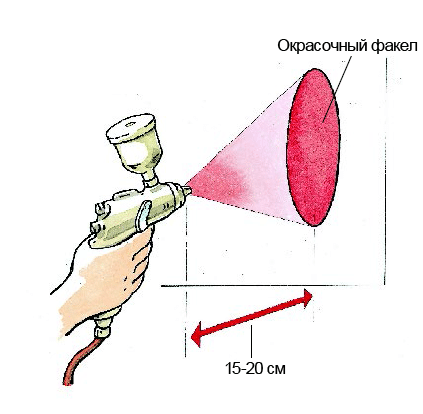

In addition, the pressure depends on how far the spray gun should be kept from the base for uniform painting, because the lower the air pressure in the spray gun, the closer you need to bring the painting gun to the surface for high-quality staining.

For different models of spray guns, the parameters of optimal performance will be different. They can be configured according to the instructions for the spray gun. It has a table with the pressure gauge that matches the settings of the gearbox, which helps maintain constant air parameters inside the spray gun. Set the necessary data, focusing on the pressure gauge, you can use the screw regulator.

The optimal settings for the air pressure at the exit of the nozzle vary depending on the model of the spray gun. But usually it is for spray guns, depending on the pressure:

- high - 3 atm .;

- normal - 2.5 atm .;

- low - 2 atm.

Efficiency, uniformity and subtlety of paint application depend on these parameters.

to contents ↑Types of pressure gauges

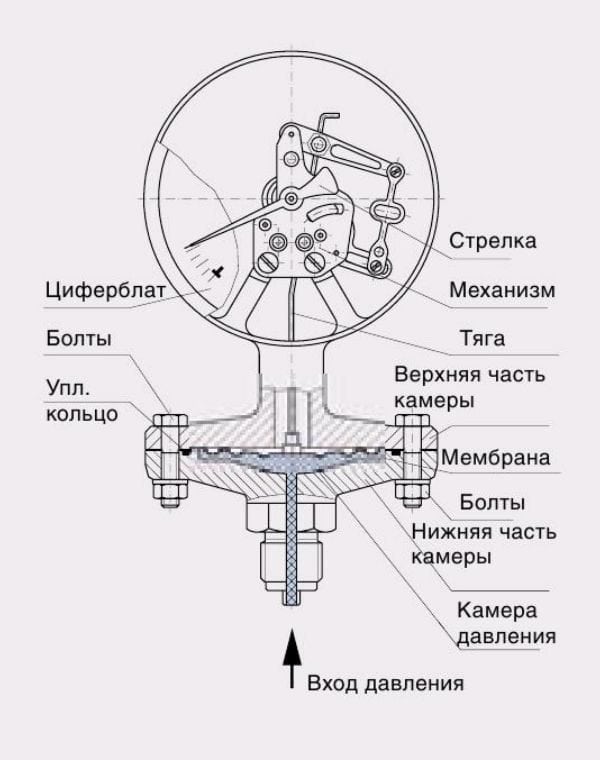

To take indicators, depending on the model of atomizers, various types of sensors are used:

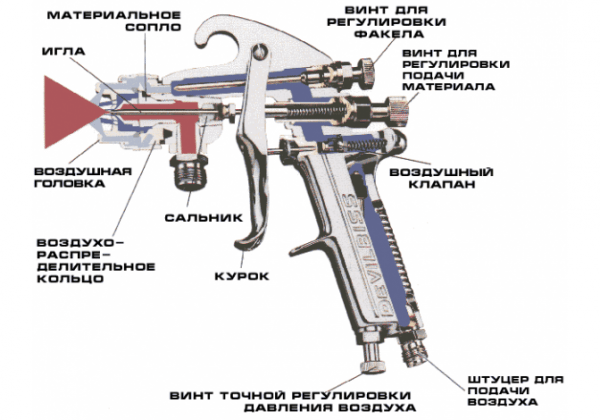

- Spring loaded. The simplest in design. They are most often installed on coloring instruments, allowing data to be obtained over a fairly wide range. Durable, very rarely fail.

- Membrane In them, the active element is a sensitive membrane stretched between two bases. And the membrane determines the flow rate of the air mixture and dye. They are rarely installed on painting models.

- With pressure regulator. Such a device can be built-in or mounted on the handle of the paint spraying mechanism. With additional installation on the painting unit, it only allows you to read data, but does not affect the operation of the spray gun.

- Digital is a new word in technology. It is rarely installed, as a rule, while on expensive professional models. The air sensor installed on the spray gun allows you to accurately adjust the ratio of air and paint compositions. The painting unit may already be mounted or available as a separate accessory.

If the dyeing device does not have a manometer, then you can determine the pressure by ear, by the nature of the hiss of the jet emerging from the nozzle. Professionals who have long been engaged in decorative work, this is easy to do. They rarely look at sensor readings, trusting their senses more.

to contents ↑But for beginners it is difficult - when the pressure of the spray jet changes, it is immediately reflected on the painted base.

Features spray gun settings

In order for the dye to lie evenly on the surface to be painted, it is necessary to adjust the air and paint supply parameters. For this purpose, it is necessary to conduct several tests that determine the quality of the settings of the spray gun:

- To begin testing, the spray gun should be placed in spray mode and quickly sprayed along an unnecessary surface. If the dye layer is evenly laid, it means that the supply pressure of the dye is not necessary to regulate. If the droplets of paint lay uneven on the surface, then you need to adjust the gearbox settings with the help of the regulator.

- Turn on the device for a couple of seconds, and then turn it off. If traces of spraying paint are visible on a test bench (an unnecessary piece of material), then the pressure of the dye must be reduced.

- Irregularities in the stain after a short ejection of the dye means an incorrect ratio of the air-dye mixture. To correct this drawback, you need to adjust the settings of the gearboxes.

- In addition to the pressure gauge, you should check the condition of the needle and nozzle, the quality of their installation.

If the adjustment is done correctly, then the spot of paint during vertical and horizontal application will have the same characteristics, and in width it will correspond to the parameters specified in the instructions.

to contents ↑Some subtleties of the adjustment process

During the operation of the spray gun adjusted according to all parameters, it seems that not a paint but a cloud of colored dust comes out of its nozzle - this is precisely what all the settings are correct.

It may be difficult to set up air reducers and a supply of a coloring solution for high-quality uniform painting of a product without experience, but a few useful tips will help to cope with this task:

- In the case when the spot falls on the test base "eight", this means that too much air pressure. It must be reduced by carefully moving the control lever.

- With a lot of uneven coloring drops on the test bench, it is necessary to add an air mixture feed. Only empirically it is possible to determine which position of the regulator will be optimal in this situation.

Using such tests, it is possible to achieve the optimal ratio of operation of the air intake reducers and the paintwork composition, ensuring uniform painting of the product.

to contents ↑Difficulties in adjusting the device

Many, for the first time picking up a spray gun, believe that it is equipped with a too tricky mechanism for adjustment. But the tactics of actions depend only on the installation location of the pressure gauge:

- On the instrument itself. In this case, you need to set the data specified to the factory settings.

- Removable pressure gauge, which is an optional accessory for the spray gun. It is attached to the handle of the device. You can also configure it according to the finished table in the attached instructions.

- Regulator on an autonomous air supply source. To do this, you can use any air compressor. The adjustment is carried out at the point of attachment of the air supply pipe to the spray gun when it is selected which optimal ratio between the air flow from the compressor and the coloring mixture in the spray gun is to be chosen.

Knowing what parameters are necessary for high-quality staining, you can easily, focusing on the pressure gauge and the nature of the test spot, select the necessary settings by working with the regulator. When the paint sprayer is prepared for such a technique, obtaining a beautiful and high-quality painted surface will not take much time.