PVC boats are very comfortable, therefore they are very popular among anglers. They are lightweight, practical, easy to carry. But, despite the advantages, products can be damaged during storage or operation. Repair of small defects can be carried out at home without contacting the workshop. High-quality glue for PVC boats will help, with which you can make scheduled or emergency repairs.

- Choosing glue for PVC boats

- Types of adhesives and popular brands

- "Moment"

- Polychloroprene adhesive

- Polyurethane adhesive

- Kleyberg (Kleiberg)

- Texacol ("Texacol")

- Bostik (Bostik)

- Sintacoll (Syntacol)

- "Master"

- "Liquid Latka"

- "Radical"

- "Gum"

- Rubber glue "NK"

- Glues 88 CA, 88 NP, 88 N

- Liquid patch “Three whales”

- Other adhesives

- Glue a rubber boat - step by step instructions

- Tools and Tools

- Find damage and determine their degree

- Repair damage

- Stripping

- Degreasing

- Training

- Gluing

- Carrying out repairs in different situations

- Punctures, pierce fishing

- Large punctures

- Cuts of the bottom and ragged holes

- Gluing Oarlocks

- Seam sealing

- Bonding tapes

- Glue transom

Choosing glue for PVC boats

Correctly carried out repair work is a guarantee of the normal service of the craft, as well as human safety on the water. If you seal the boat poorly, it can be depressurized, and the cavity will begin to fill with water. It is usually recommended to use the glue that comes in the boat repair kit, but such a tool has a small volume and quickly ends. Therefore, if the product is damaged, you will have to select a new glue, which must meet a number of requirements:

- Strength and elasticity. The best glue - one that has a high level of adhesion to the PVC surface, allows you to create a strong and durable joint that does not break with time. Cyanoacrylate adhesives are not suitable because they do not have sufficient elasticity: when launching and pumping the boat, the seam will begin to crumble.

- Lack of stickiness, quick drying. To repair the boat in the field, the adhesive must dry quickly. It is worth evaluating the properties of the glue in advance, applying it with a thin layer and checking for adhesion after 5-7 minutes. Poor quality products will stick to your fingers.

- Special composition. Universal adhesives are less suitable than special purpose products that are designed specifically for PVC, rubber. Typically, such adhesives better tolerate temperature extremes, have increased heat resistance and frost resistance, are not destroyed by contact with water. Some adhesives even endure immersion in sea water.

to contents ↑High-quality glue can not be cheap, and you should not save on your safety. You need to purchase a tool of sufficient volume so that it is enough for repairs. The glue should not contain components that spoil PVC, otherwise the boat will be irreparably damaged.

Types of adhesives and popular brands

All adhesives can be divided into two groups - one-component and two-component. The first are sold in finished form, they do not need to be bred, mixed, but can be immediately used for repair purposes. The second are sold complete with a hardener, which is added to the main composition in a certain ratio.Most often, two-component adhesives are based on epoxy or polyester resins. Below are the most popular means by which PVC boats can be glued.

to contents ↑"Moment"

Clay "Moment" is a universal composition that can be found in any store, it is sold even at the cash registers of supermarkets. "Moment" is affordable, economical, has a high degree of water resistance, is not afraid of the influence of gasoline, industrial oils. After drying, the glue line will be transparent, barely visible on the product.

The instructions for the “Moment Universal” adhesive noted that it is suitable for soft and hard PVC, as well as other materials: rubber, wood, glass, metal. Of the minuses, a low degree of resistance to UV radiation can be called, because the adhesive seam can deteriorate from long exposure to the sun. To work with glue you need to use personal protective equipment, since it contains solvents. Drying time is 24 hours.

to contents ↑Polychloroprene adhesive

Adhesives of this type are one-component compounds, excellent for repairing rubber and PVC boats, rubberized materials, and wetsuits. The composition has a high degree of moisture resistance, very durable, after solidification forms an elastic seam. Glues are heat resistant and do not deteriorate when exposed to the sun.

Polyurethane adhesive

Polyurethane compositions can be one-component and two-component. They are used for gluing PVC, acrylic, rubber and rubberized fabrics, boats, banners, awnings. The elastic joint of the glue can last at least 10 years. The advantage is the lack of yellowing of the seam over time. The problem will only be the removal of funds in contact with places not intended for this, so you need to work with it carefully.

to contents ↑Kleyberg (Kleiberg)

Glue under the Kleyberg brand is a professional tool for PVC. It is based on polyurethane, contains organic solvents and stabilizing additives. The glue is waterproof, dense texture, high adhesion. Kleiberg also has disadvantages - the composition does not tolerate lower temperatures: it would be undesirable to use the product at +5 degrees and below.

Texacol ("Texacol")

Texacol glue is used for the production and repair of PVC products. It contains polyurethane as well as reinforced polyvinyl chloride. The tool is available in two versions - one-component and two-component. The adhesion of the composition is very high, the application is simple, the adhesive joint does not require heating with hot air.

Bostik (Bostik)

Two-component polyurethane adhesive with wax on organic solvents "Bostic Vinicol 1520" is widely used for repair of PVC boats. It is necessary to apply glue with a brush, it dries quickly, has great resistance to high humidity and direct action of water. The composition requires vulcanization, after which it becomes very durable.

The maximum temperature that the adhesive can withstand is +80 degrees. After solidification, it does not respond to the influence of oils, alcohol, acetone. The glue line does not deform; it serves for many years. Minus - the need for a respirator, because the glue is highly toxic.

to contents ↑Sintacoll (Syntacol)

Syntacol polyurethane compound will also become an assistant in boat repair. It has a quick initial setting and is resistant to high temperatures. To gain strength, the agent must be mixed with the hardener, after which it will reliably protect the defect from leakage. Before use, the surface must be degreased well, otherwise the adhesion quality will be reduced.

to contents ↑"Master"

Glue "Master" is created on the basis of synthetic rubber Desmocoll, is a professional tool that is resistant to moisture. The glue is sold in compact tubes, has a convenient nozzle, dries very quickly. The tool is ideal for patch repairs.It can be used only at temperatures from +18 degrees, but the operation of products is possible at sub-zero temperatures.

to contents ↑"Liquid Latka"

It is a solvent-based PVC suspension. Glue helps repair without patches. The solvent destroys the structure of PVC, and the main component restores the material. As it dries, a strong layer is formed, merged together with the fabric of the boat. "Liquid patch" allows you to repair quickly, easily, you can work with it without brushes and the use of a hairdryer. For large holes, glue is not suitable, you will have to cut a patch. "Liquid patch" is not suitable for repairing hardware.

to contents ↑"Radical"

This is a universal one-component adhesive that firmly connects PVC, rubber, neoprene, and other materials. In its composition it includes organic resins, solvents, chloroprene rubber. Glue can be used at low temperatures, withstands high blood pressure, physical activity, does not break down even in sea water. The temperature range for operation is -60 ... + 80 degrees.

"Gum"

The one-component adhesive of this brand is made on the basis of natural rubber, therefore the seams created by it are water resistant, highly elastic and durable. The tool is used for bonding rubber, rubber-fabric items and PVC products.

to contents ↑Rubber glue "NK"

Glue means "NK" is made of artificial rubber, nephras. Bonding of rubber and PVC is carried out without vulcanization - by the cold method. After hardening, the adhesive joint can be operated at temperatures of -50 ... + 70 degrees, it does not deteriorate from the action of water (fresh and salty), vibration, and is not exposed to infection by fungi and mold.

Glues 88 CA, 88 NP, 88 N

The adhesive composition 88 CA is produced by processing natural rubber with the addition of gasoline, it is a flammable agent. It is intended for gluing rubber and fibrous materials in a cold way. After drying, a durable elastic film forms on the surface. The product guarantees high adhesion to PVC, as well as to metal, concrete, glass, fabric, wood.

88 NP rubber adhesive is characterized by higher tensile strength. He is not afraid of water, he easily withstands operation at -50 ... + 70 degrees, can be applied hot and cold. Due to its special strength, the product will last a very long time. It is recommended by professionals for the repair of boats made of polyvinyl chloride.

Glue 88 N also consists of natural rubber, but is enriched in butyl-phenol-formaldehyde resin and diluted with gasoline. It is used for products that are not exposed to thermal stresses, so a repaired boat cannot be stored in direct sunlight.

to contents ↑Liquid patch “Three whales”

This glue is a specialized composition for the repair of PVC boats. It is sold in tubes of 20 g, has a green color. After application, the agent completely penetrates the base of the material, updating the damaged area. Ready seam retains all surface properties: it does not crumble in frost, is not afraid of heat, is resistant to sunlight, is not scratched.

Other adhesives

If none of the above means is available for sale, you can purchase another glue from the following list for boat repair:

- "PUR-glue 508" - has the highest strength and elasticity, is used to restore any fishing equipment;

- "RK-2" - is used for bonding all types of rubber, PVC, is highly resistant to salt and fresh water;

- Penosil Fix Go - glue-cold welding based on epoxy resin, used for emergency boat repairs, characterized by excellent strength.

Glue a rubber boat - step by step instructions

To repair a damaged boat, you must purchase the adhesive in the right amount, as well as get a number of other devices.

Tools and Tools

To restore the integrity of the product, you need to prepare a patch from any improvised rubber items, for example, from an old camera. In some cases, a patch is not required, and the defect can only be removed with glue. Also, in different situations, work may require:

- sharp knife or scissors;

- degreasing agent - alcohol, toluene, white spirit;

- a rag to wipe the bonding place;

- building hair dryer or lighter;

- strong kapron threads;

- rubber roller;

- sandpaper;

- marker (pencil).

Find damage and determine their degree

Most often, the owner of the boat notices that she began to lower, when pumping or directly on the water. Large punctures are visible to the naked eye. If they are no more than 5 cm in size, you can repair yourself. To eliminate larger defects, you will have to contact a workshop or tire fitting. Of course, the patch can be glued to a large hole, but it is unlikely to withstand much pressure.

How to detect small holes? Here are the main ways:

- Lowering the inflated boat into the water. If there are holes, air will escape from them in bubbles. True, in muddy river or lake water it is sometimes difficult to notice them.

- Lubrication with soapy water. If the inflated chamber is moistened with soapy foam, the latter will bubble strongly when air escapes from the hole.

When the puncture is localized, it must be marked with a bright marker or pencil. Even the smallest holes should be repaired, because under pressure their expansion is a matter of time.

to contents ↑Repair damage

Many defects of small and medium sizes are cleaned according to the same scheme, it is only important to observe the correct sequence of actions.

Stripping

First, the defect area must be cleaned of any dirt, dust. Some masters prefer to carry out additional processing of the material with sandpaper, but if there is a risk of damage to PVC, this item is better to skip. It will be enough to wash the problem area well and dry it.

Degreasing

The ideal way to eliminate the grease film is alcohol (vodka) - this solvent will certainly not damage PVC. It is necessary to be much more careful with acetone and other solvents, since they are able to corrode the material. Wipe it off effortlessly with a soft cotton pad.

to contents ↑Training

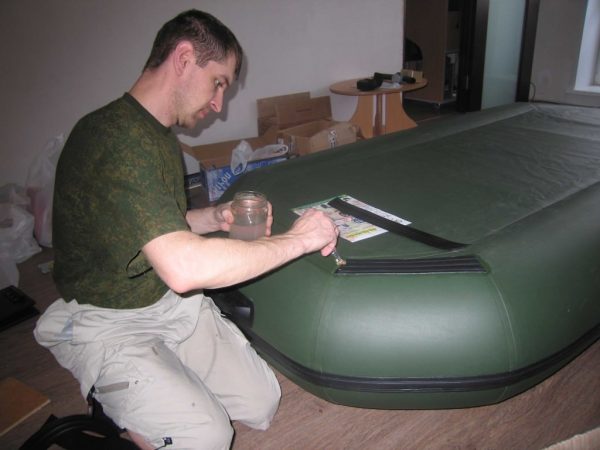

After washing, drying and degreasing the surface, the boat is laid on a flat base, stretched so that there are no wrinkles. Some adhesives require heating the surface, which will require a building hair dryer. The warming up time can be read in detail in the instructions for the glue.

to contents ↑Also, as a preliminary event is the manufacture of a patch. The ideal option is to take the finished one from the repair kit. If this is not possible, a patch of rubber is cut out of the rubber. It should be larger than the hole by 3-5 cm in diameter, blocking the hole on each side. The patch is made round or oval, the main thing is that it does not have sharp corners, otherwise its service life will decrease.

Gluing

If surface heating is required, pass along it with a construction hairdryer, after which they immediately lay a patch so that the material does not have time to cool. When heating is not required, grease the base and the patch with glue, wait 5-10 minutes, then tightly lay a piece of rubber on the puncture area. Next, they thoroughly roll the base with a rubber roller, press the place with a press and send it to dry for 2 days (minimum).

to contents ↑

Carrying out repairs in different situations

It happens that a defect is formed of a large size or a special shape, location. In this case, the repair may have some features.

Punctures, pierce fishing

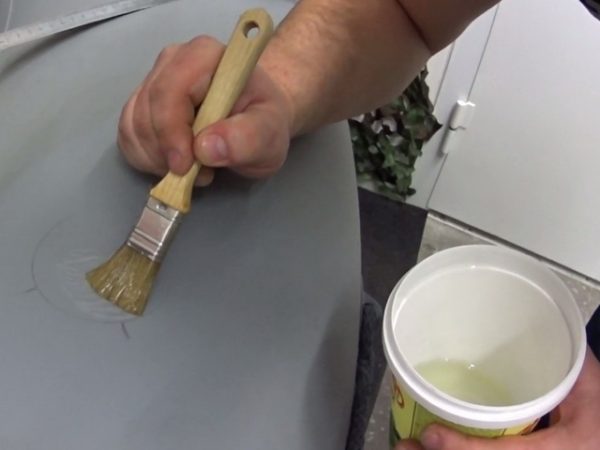

If the puncture occurred away from home, you can carry out emergency repairs. A patch is cut out of the rubber at hand, glued to the place of damage, pressed for 30 minutes. After returning home, you will have to disconnect the patch and repeat the work, but only with the observance of the mandatory points - cleaning, degreasing. Some adhesives should be applied in this way:

- make the first adhesive layer on the patch;

- let it dry for 5 minutes;

- apply another layer to the base and patch;

- 5 minutes later lay the patches;

- roll with a roller or a bottle filled with hot water.

Large punctures

When the damage has a size of more than 5 cm, 2 patches should be applied to it. One is attached from the inside, the second is placed outside. The inner part is glued first, and only after it has dried, the external patch is attached. Too large holes are repaired in workshops.

There is another option for repairing large-sized holes:

- rinse, dry, degrease the surface;

- stitch the edges with harsh or kapron threads;

- stick a puncture in two patches;

- let the glue dry completely.

Cuts of the bottom and ragged holes

The bottom is recommended to be repaired in the workshop - this will be much more reliable. Without vulcanization, a high-load patch may come off. Nevertheless, small defects can be sealed on their own using two patches: external and internal. To strengthen the strength on these patches you can glue one more, but larger. Torn holes will first have to be sewn up, and then glued with patches.

to contents ↑Gluing Oarlocks

The rowlock is the element of the vessel in which the oar is fixed. Because oarlocks are subject to high loads, they can come off the ground or just burst. Before repair, the old oarlock must be dismantled, pre-heating the junction with a construction hairdryer. After gluing a new part using rubber or polyurethane adhesives. The adhesive compositions are applied in 2 layers (the second - 5 minutes after the first). The glued place is again heated with a hairdryer, allowed to dry for 1 day.

to contents ↑Seam sealing

The repair process is carried out in a similar way, only two latches are necessarily applied - on one and on the second side of the seam. All actions are performed carefully so that there are no gaps in the bends. After the glue has dried, it is necessary to prepare a thick soapy solution or take shaving foam, cover the damaged area. If air bubbles do not appear, it means that the repair was carried out efficiently.

Bonding tapes

It is only necessary to glue the tapes at the seams when the boat is fully pumped up, otherwise the quality of the connection will be low. Old tapes can be removed without problems, but glue can be difficult to remove. You will have to use sandpaper, solvent, gasoline.

After the glue is applied to the tape and the base, after 5 minutes another layer is applied. After 10 minutes, the tape is well pressed to the previous place. For normal joining, it is necessary to make the glue line more than the width of the tape by 10 mm in each direction.

You need to start gluing the tape from the side of the bottom of the boat. The material is laid with tension to ensure maximum contact with the surface. After gluing, the tape is ironed with rags.

to contents ↑Glue transom

Transom - the area on which the motor is mounted. Under such a weight, this element often deteriorates and requires repair. Typically, a polyurethane adhesive is used to adhere this part, which has sufficient adhesion and elasticity. The work is carried out in the same sequence: cleaning, degreasing, applying glue, pressing the parts, waiting for time to dry completely.

In order to prevent damage to the boat, it must be properly stored and operated. If the product is put into storage in a slightly deflated state, covered with an awning, the risk of tearing and puncture is reduced. The boat must be transported carefully, and when swimming it is important to exclude friction, scratching, touching sharp objects. These tips will help the fisherman avoid problems and wasting time on repairs.

What a huge amount of adhesives exist. The article was very useful to me.

Excellent, informative article. Thanks to the author!

Thank you for the useful article))) Just in the summer, I tore the boat against the root, sealed it. Then I went out onto the water and caught fish as usual, I feel something is wrong, and it turns out I am “EXCELLENT MASTER” but now I realized my mistake. I will redo it on your advice)