Glues Moment are known to most of us, they are produced by Henkel in a huge assortment. But not everyone knows about a special line of epoxy-based products that have a special purpose and the highest quality. Epoxy adhesive Moment can hold together most known materials, but it is necessary to take into account the features of operation.

- Scope of application

- Specifications

- The composition of the funds

- Range

- Super Epoxy Moment Transparent

- Super Epoxy Metal Moment

- Super Epoxy Formula 1 Moment

- Super Epoxy Moment Transparent In Syringe

- Super Epoxy Formula 5 Moment

- Epoxilin Moment 2 in 1

- Moment Epoxylin Mini

- Super Epoxilin Moment

- Epoxy Moment Moment

- Moment Epoxilin Duo

- Instruction for use

- Packaging, storage and safety

Scope of application

Two-component epoxy adhesive Moment is a transparent plastic composition, available in two packs for further mixing. In repair and construction, it is called universal: indeed, you can use the tool for such materials:

- metal;

- tree;

- ceramics;

- leather;

- china;

- glass;

- faience;

- crystal;

- marble;

- brick;

- pearls;

- bone;

- gems.

An adhesive joint will be equally reliable when using Moment on surfaces of various metal alloys, artificial and natural stone, concrete, fabric, cork. From synthetic plastics Moment perfectly sticks together rigid PVC, plexiglass, polystyrene, polyamide, polycarbonate. It is possible to combine both surfaces that are uniform in composition and heterogeneous - for example, ceramics with wood, leather with glass.

to contents ↑The tool can quickly repair cracks, dents, chips when repairing cars, furniture, household items and electronics. It is ideal not only for gluing, but also for sealing products. But there are still restrictions on the type of materials: you can’t apply the moment on rubber, polyethylene, silicone, teflon, polypropylene.

Specifications

Glues of this series are often called “cold welding”. They provide a very strong, continuous bonding due to the presence of epoxy in the composition. The main technical parameters are as follows:

- color - transparent when applying a thin layer, does not tend to turn yellow after drying;

- smell - odorless;

- conditions for application - humidity up to 65%, temperature + 10 ... + 30 degrees;

- heat resistance of the finished seam - up to +60 degrees at high load, up to +150 degrees without load;

- frost resistance of the seam - up to +30 degrees;

- initial hardening - in 20–40 seconds, curing - in 5 minutes, sufficient adhesion strength - 2 hours.

The description of the means of this line says that the adhesive joint is resistant to moisture, does not decompose under the influence of household chemicals, oils, alkalis and solvents. The hardened adhesive can be stained, and any kind of paint is acceptable. The glue does not expand after curing, does not shrink.

The advantages of using the series are as follows:

- ease of application - it is easy to measure the glue, it easily covers the base due to its plasticity;

- the ability to apply the material several times - tightly closed packaging ensures the safety of the product;

- resistance to mechanical stress - after hardening, the seam can be grinded, processed, polished, drilled, the structure of the formula will not be violated;

- low price - for such a quality product you will have to pay no more than 120-200 rubles.

to contents ↑The disadvantages include a small elasticity of the connection, so it is advisable not to expose the joint to significant vibration, movement. The moment can be frozen, after defrosting its properties remain the same.

The composition of the funds

Glues of a series are presented in two packings. The following components are contained in one bottle: epoxy resin, modifiers, fillers. The second bottle contains a hardener for epoxy (based on polymercaptan), modifiers. Typically, a 6 ml serving is consumed at a time, but can be divided if necessary.

Why do we need a two-pack release form? The epoxy resin cures only after the start of the chemical polymerization reaction, which provides the introduction of a hardener. As the components join, a high-strength adhesive joint is obtained, which is difficult to break and almost impossible to tear. Included with some types of adhesives are trays for mixing the components.

to contents ↑Range

It is worthwhile to consider in more detail the Moment line, which includes 10 adhesives for different purposes, although almost all of them are considered universal.

Super Epoxy Moment Transparent

Super Epoxy Moment is an absolutely transparent composition, which is a universal tool for bonding any surfaces. It is highly resistant to moisture, oils, solvents. Suitable for internal, external work. After 60 minutes, the product gains sufficient strength. It is especially recommended for joining porcelain, earthenware, crystal, glass, fiberglass, various plastics.

to contents ↑Super Epoxy Metal Moment

Due to the addition of special modifying additives, the adhesive is suitable for joining any metals, alloys, it does not deform and does not expand after curing. The tool is suitable for hard PVC, cork, marble, stone, wood, but it demonstrates the best performance on metals. Indications for use:

- connection, repair of metal parts;

- repair of cracks, leaks in pipes, tanks.

Super Epoxy Formula 1 Moment

The tool is available in a syringe with a unique nozzle in the form of a mixer. This helps to accurately dose and quickly mix the components directly inside the syringe. Such glue is better applied to the surface, it is more comfortable to work with it. The tool is universal, suitable for most materials (except for Teflon, polypropylene, polyethylene, rubber).

Super Epoxy Moment Transparent In Syringe

The glue is similar to Means Super Epoxy Transparent, only available in a syringe with a dispenser. It is considered a universal composition, has no specific application.

Super Epoxy Formula 5 Moment

The product is available in a syringe with a mixer, which allows you to mix the components without using dishes, without contact with the skin, quickly and reliably. Additional tools are also not required. The glue dries in 5 minutes, after 8 hours it can be drilled, polished, sanded. This composition is ideal for filling various cracks, chips, dents, suitable for the restoration of all types of building materials.

to contents ↑Epoxilin Moment 2 in 1

Epoxylin Moment 48 g - this is the second direction of the Epoxy-based Moment line products. They are a putty in the form of a cylinder, where under the first component is the second (hardener). Both substances should be kneaded by hands, mixed, after which they will react. Epoxylin 2 in 1 is suitable for adding corners, missing elements, sealing defects.

to contents ↑The glue does not expand; it is resistant to moisture and oils. It hardens in 10 minutes, gains high strength in 70 minutes, after 2 hours it has a strength of about 50% of the final.Universal, suitable for all types of materials except Teflon, polyethylene, rubber.

Moment Epoxylin Mini

The product is similar to that described above, but is available in a small convenient package (6 g). It is used for restoration, repair of any product, except in contact with food.

Super Epoxilin Moment

An analogue of Super Epoxylin 2 in 1, but it is produced in a package of 5 * 48 g. It is intended for a large amount of work.

Epoxy Moment Moment

Adhesive in the form of putty, which provides the highest strength when working with metal surfaces and alloys. Ideal for bonding:

- gland;

- steel;

- copper;

- brass;

- lead

- stainless steel;

- aluminum;

- tin.

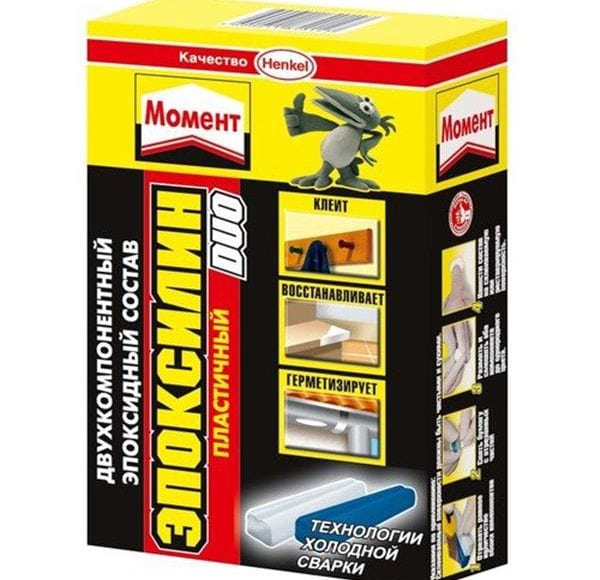

Moment Epoxilin Duo

Epoxylin Duo differs only in increased packaging - it includes 2 cylinders of 50 g of high-quality, reliable glue. It can be used for all types of materials, the composition is considered universal.

Instruction for use

All gluing procedures are carried out only with gloves. Glue that gets on your hands is difficult to remove, it freezes instantly, and it can also cause a burn. Special knowledge and skills when using the tool is not required, the instructions for use are simple:

- Clean bonding surfaces. For this purpose, water, degreasers, paper, sandpaper and other convenient devices are used. Ultimately, there should be no dirt, dust, grease on the base.

- Trim the tip of the nozzle from the syringe, mix hardener and resin in equal proportions. Typically, a kit has an attached container and a spatula for mixing.

- Within 3-5 minutes, apply the mixture to both surfaces. After 5 minutes, the epoxy adhesive will be unusable. Press parts, lock for 2 minutes.

- Leave the product for a day until active use. To improve the quality of the joint, you cannot move the parts for the specified time, otherwise the seam may turn out to be uneven. The joint can be grinded and polished after 8 hours.

- Excess glue that has come out must be removed immediately. Fresh spots of glue are removed with acetone; dried ones will have to be cleaned mechanically with difficulty.

to contents ↑

Packaging, storage and safety

Glue products with this tool only in a well-ventilated area. Contact with skin causes burns, allergies, irritation, dermatitis. In case of contact with eyes, rinse immediately and consult a doctor! You can not use glue to connect dishes in contact with food, it is also harmful to aquatic organisms.

During storage, the product should be protected from children! It is necessary to avoid the release of residues into the environment, while it is allowed to dispose of the Moment as household waste. Guaranteed shelf life - 36 months at a temperature of + 5 ... + 30 degrees. In case of freezing, it is recommended that the glue be kept at room temperature for 24 hours before use.