There are situations when you need to glue something, but the necessary funds are not at home. Buying an adhesive is optional. You can always make it yourself if you find the simplest materials. "Folk craftsmen" make glue from polyfoam and solvent. The result is a tool no worse than a store, suitable for a variety of purposes.

- Styrofoam Adhesive - Application

- Glue Instructions

- Features of the adhesive

- What polystyrene is needed - features of the preparation of glue

- Instructions for the preparation of glue from linoleum

Styrofoam Adhesive - Application

Foam glue, despite the home-made composition, has powerful strength characteristics. It has a good indicator of adhesion to different surfaces. Here are the main areas of its application:

- sealing roof cracks, joints of slate and roofing material;

- bonding of interior items, utensils, household products, furniture;

- fixing ceiling eaves, plinths;

- connection of plates, individual pieces of extruded polystyrene foam.

The life of the product is long - you don’t have to worry about disconnecting the fastened parts. There is only one caveat in the use of home glue. It is suitable for hard materials, but on rubber and other soft raw materials it is better not to use it. The product will cause unnecessary hardening and may damage the product.

to contents ↑Glue Instructions

How to make glue at home, than to dissolve polystyrene to get a quality product? The preparation is simple, but follow the step-by-step instructions clearly:

- Get solvent out. They make an adhesive composition of gasoline and acetone, another solvent (toluene, xylene) will do, but they have strong toxic properties. The easiest way to dissolve polystyrene with gasoline.

- Prepare expanded polystyrene. The larger the pieces, the thicker the glue mass will be.

- Pour solvent into a small jar. Gradually add polystyrene broken into crumbs.

Polystyrene will begin to dissolve in the liquid almost immediately, only a viscous mass will remain from it. You can continue to add crumbs to make a large volume of glue. It is also allowed to take a viscous mass from the solution and use it for its intended purpose.

It is recommended to stick products without delay. The composition is applied to the surface with a brush, leveled, the parts are pressed tightly against each other. Leave to dry completely (the process lasts 24 hours). Excess glue that has come out must be removed immediately - after drying, stubborn streaks are obtained, which are difficult to remove.

There is another method of making glue. Polyfoam should be crushed directly where it is supposed to stick together defects. Next, the solvent is carefully poured into pieces. The material melts, becomes like honey and begins to glue. It fills cracks, joints, serves as an excellent sealant. The better the finished product is mixed, the stronger, more reliable the adhesive joint will be.

to contents ↑Features of the adhesive

The use of solvents always poses a safety risk, so it is important that all precautions be taken. Gasoline, acetone are combustible materials, they are highly flammable. Work is carried out far from sources of fire, smoking is strictly prohibited nearby! It is advisable to work in the fresh air or in a room with good ventilation. Otherwise, there is a risk of breathing vapor solvent.

You can also use glue as a protective film on wood products, other materials. You will have to make the solution more liquid, not to add too much polystyrene to it. Cooking a large portion of the product is not worth it, it instantly freezes and loses its properties. The drying speed depends on the thickness of the adhesive layer: for quick bonding, a mass is applied with a thin smear.

to contents ↑How to replace the foam in the composition if it is not available? Any plastic product is suitable, for example, a tennis ball cut into pieces. The technique for making glue is similar.

What polystyrene is needed - features of the preparation of glue

There are several varieties of expanded polystyrene. Pressless (granular) in appearance is a set of connected balls that crumble a lot. It is he who is best suited for the preparation of glue. Pressureless foam quickly dissolves in acetone or gasoline, becoming an adhesive mass.

Pressed polystyrene foam is not so easy to crumble. It can also dissolve, but because of the difficulty in the preparation of adhesive compositions is not used. Extruded polystyrene is strong, uniform, with a smooth surface. For the manufacture of adhesive mass, the material is not suitable.

You can use foam glue on an ongoing basis - it serves for a long time, is not afraid of frost and heat. With the help of the tool, it is possible to save on repairs, if you follow the tips and rules.

to contents ↑Instructions for the preparation of glue from linoleum

Linoleum is not only a beautiful, practical flooring. There is a recipe for universal glue, it is prepared from the remnants of an old flooring. To make such a home remedy is quick and easy, no special components are required. DIY glue from linoleum is a reliable, strong composition, which is suitable for joining such materials:

- ceramics;

- metal;

- wood;

- plastic;

- glass;

- rubber;

- cardboard;

- paper;

- china.

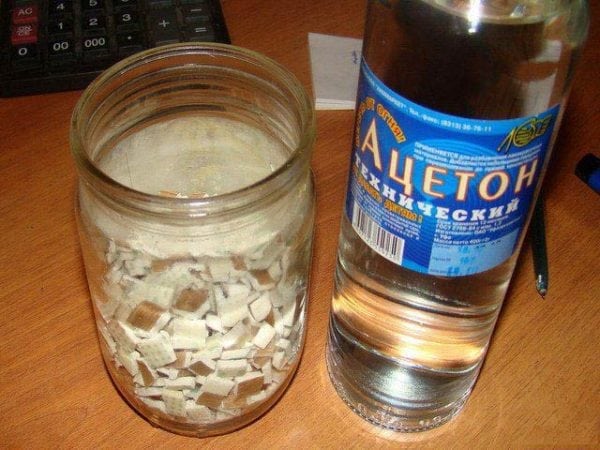

The components for the manufacture of glue are scraps of linoleum and acetone. You will also need a glass jar of 1 liter or more with a tight-fitting lid. There is an important condition: if the flooring is without a substrate, it is used in its original form. If there is an insulating layer, it must be torn off.

Step-by-step manufacturing technique:

- Wash a piece of flooring with soap. The material must be completely clean.

- Dry linoleum by wiping with a rag. Cut into small pieces (several millimeters) with a sharp knife or scissors.

- Take a dry, clean jar. Fold the chopped pieces.

- Pour material with acetone so that it completely covers the scraps.

- Put the closed jar in a dark, not cold place.

Linoleum begins to gradually disperse in a solvent, the whole process lasts about 24 hours. The more often you shake the contents of the jar, the faster the composition will be ready. In just a day, they can glue any surfaces, details. To do this, put a little funds on the base, distribute with a thin layer, press the product and fix it.

Using this glue is easy - it dries as acetone evaporates in a few seconds. By adding an equal amount of wood shavings, you will get high-quality putty for wood or window putty. The introduction of chalk (1: 1) will prepare an excellent mastic for laying tiles.The cost of this glue is very low, and the quality is not inferior to the store one, so you can use it everywhere.

is it possible to glue the clinker tiles onto the furnace heater where there is a high temperature and a constant drop during the day and night cooling. The fact is that in the summer I did repairs, put the tiles on the stove heater for heat-resistant glue, winter came the result of my work all the tiles were removed and the glue remained so that the glue could not be removed from the heater, you can glue the tile like on liquid nails. Maybe someone will tell friends I really need a hint, can anyone come across a similar situation