Wood adhesives are very popular in furniture manufacturing and carpentry. The masters consider the Titebond glue (Taitbond) to be a quality tool, or rather, its entire line produced under this brand. The manufacturer - the American company Franklin International - monitors the quality of products, and also guarantees the highest moisture resistance of the compounds among analogues.

Varieties and scope of glue

Titebond wood adhesives are high-quality carpentry compounds for professional and home use. They have a different basis depending on the specific purpose: artificial rubber, polyurethane, aliphatic resins. The products also contain polymers, protein compounds, water, various modifiers and plasticizers.

In total, there are 25 types of adhesives in the Tytbond line, but universal single-component products with strong water-repellent properties are most common on the domestic and European markets. Their technical characteristics are unique: with proper preparation of the base and following the instructions, the glue line will be practically not affected by moisture. Most adhesives can be used for such purposes:

- laying parquet boards at home, in offices;

- restoration of old wooden coatings;

- Furniture assembly;

- bonding of wooden and plastic parts;

- production of plywood products;

- various repair work.

Depending on the specific type of waterproof adhesive, its properties and purpose may be different. The main types of adhesive compositions "Tittbond":

- Original Wood Glue. Glue with a red label is used for repair, restoration of musical instruments, in the production of such products. After drying, it forms a solid, non-plastic seam, which does not interfere with the normal sound, does not change the properties of the tree.

- Titebond II Premium. This product has a blue sticker, it is also moisture resistant, while not subject to solvents. The glue line will be quite elastic, the initial setting - more powerful. Due to environmental friendliness, the adhesive can be used for gluing wooden cutting boards, other products that are indirectly in contact with the products. Also, adhesive number 2 is used to repair room, garden, other outdoor furniture, mailboxes, veneer, laminate, plywood, fiberboard, particleboard products. It is packaged in bottles, cans, buckets and even barrels with a volume of 0.037-100 liters.

- Titebond III Ultimate. Glue “Taitbond 3” with a green sticker is available on a water basis, has an opaque consistency, cream color. All polymers in the composition are harmless to health, because the tool is well suited for products in contact with food. Most often, glue is used in the food industry, but it can also be used for repair, restoration of plywood, veneer, other types of wooden surfaces, as well as plastic. It is suitable for outdoor and indoor use, but is not suitable for products placed in water.

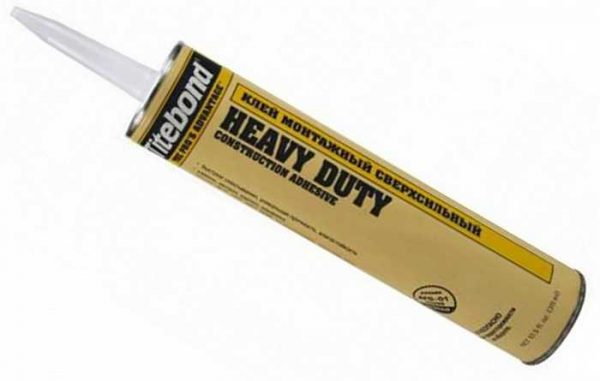

- Titebond Heavy. This is a super strong mounting adhesive, available in a yellow tube. It contains artificial rubber, due to which it does not harm any kind of wood, can be used even for gluing wet, frozen wood. Ready adhesive joint is elastic, not subject to destruction, flexible, does not deteriorate from mechanical stress. In addition to wood, this glue is suitable for gluing ceramics, slate, organic glass, natural and artificial stone, fiberglass, concrete, ceramic parts.

to contents ↑

Adhesive Characteristics

Despite the possibility of professional use, the series does not require special skills, knowledge during application. They are easy to use, it is important only to carefully read the instructions. A normal tool, including a metal one, is suitable for work, the glue does not stick to the metal, and all devices can be easily cleaned.

The main property that distinguishes Titebond adhesives from PVA, liquid nails is its high moisture resistance that meets American standards.

Other properties and technical parameters of Tytbond adhesives:

- All adhesives after hardening become transparent, despite the initial dull consistency. They can even be applied to delicate products.

- Means are resistant to freezing, after drying, the seam will withstand temperature drops to -35 degrees. Also, glued substrates can be heated up to +40 degrees, but at +100, the seam area can catch fire.

- The strength of the glue line will be very high, much higher than the wood itself. This determines the durability of the glued products. The seam is resistant not only to the action of water, but also to the influence of solvents and acoustic vibrations.

- Glues are universal, they are suitable for all types of wood, as well as other compositions based on wood, combined materials, many types of plastic. Also means can effectively fasten paper, cardboard. Elastic compounds are suitable for use as sealants.

- All errors in the work - spots, drips - until completely solidified, you can rinse with water. This is very convenient for adjusting the glue line.

- The polymerization of the composition is fast (10-20 minutes), but still not instantaneous, and correcting the position of the parts is quite possible. With increasing humidity and lowering temperature, polymerization may slow down. You can not work with the composition at a temperature of less than + 10-12 degrees.

- It is not necessary to subject the parts to strong compression, installation under the press. They stick together even with a moderate degree of fixation, adhesion will not decrease.

The most popular Tytbond adhesives have a dry residue of 48%, their viscosity is 4000 MPa / s, and their acidity is 3 pH. The material consumption is 180 g / sq. see. After opening, each agent remains suitable for use for a long time (up to 2 years) if stored at a temperature of about +20 degrees. It is undesirable to apply the composition on painted substrates, apply it in rooms with too high humidity, poor ventilation.

to contents ↑Instruction for use

You can start working with the product only at positive temperatures indoors or outdoors. For all types of adhesives, preliminary surface preparation is very important: in the presence of dust, sawdust, and other contaminants, the degree of adhesion may decrease. In addition to such contaminants, grease, oil stains should be removed, and old paint should be removed. For this purpose, use the following methods:

- grinding with a special machine, sandpaper;

- scraper application;

- washing with household or professional detergents;

- wiping with degreasers, solvents.

Before work, the glue is thoroughly mixed, applied to both parts, well pressed them. It is not necessary to use a press, but it is necessary to exclude the possible movement of products. Drying time is 10-20 minutes, during this period it is possible to remove the glue that has come out with a rag, a napkin or change the position of parts.

Work should only be in a well-ventilated area.Due to the environmental friendliness of the composition, special respiratory protective equipment may not be used, but for allergy sufferers, people with hypersensitivity and lung diseases, masks (respirators) are mandatory. If dizziness is observed, you should immediately leave work and go into fresh air. If glue gets on the skin, it must be washed well with soap, otherwise there is a risk of irritation, redness. When the product got into the eyes, they are washed well (at least 10 minutes), if necessary, consult a doctor.

Titebond glue is one of the most high-quality and convenient means that do not need to be bred, but can be used in finished form. It has the highest moisture resistance among similar compositions, is economical, therefore it is most often used by professionals.