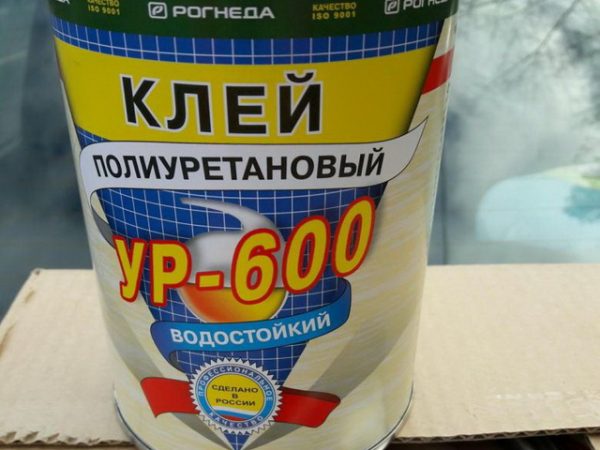

UR-600 glue is a contact adhesive based on polyurethane rubber and special additives dissolved in acetone, ethyl acetate. In appearance, it is a milky white homogeneous liquid, which when applied to the surface forms a strong, durable connection with different bases.

The glue's popularity is due to the lack of toluene and other solvents with a sharply toxic, narcotic effect, as well as excellent bonding abilities.

to contents ↑Glue application areas

UR-600 universal one-component adhesive is widely used in industry. It is in demand in the production of shoes, as it reliably fastens materials such as rubber, natural and artificial leather, nubuck, suede, hard and plasticized PVC, polyurethane, thermoplastic elastomer, thermoplastic elastomer. Glue is used in shoe repair shops, in everyday life for self-restoration of old shoes.

UR-600 is no less in demand in furniture production. With it, fabric and other materials are attached to frame bases, parts are joined, joints are strengthened. The tool has found application in the automotive industry, construction, leather goods manufacturing. To increase adhesion and strength, it is introduced into various cast products, for example, glue can participate in the direct molding of soles for shoes. At home, the tool helps in the repair, manufacture of products from:

- paper;

- cardboard (including construction);

- different types of plastic;

- tissues;

- polyurethane;

- fiber materials;

- plexiglass;

- rubber;

- TEP with a high oil content;

- metals;

- various non-porous materials.

to contents ↑UR-600 glue is suitable for PVC boats, bags, fishing boots, rubber products, because it is waterproof, very durable, and does not lose its qualities for a long time.

Adhesive properties

Due to its suitability for a huge list of materials, including highly plasticized, the adhesive is considered universal. It compares favorably with its analogues in that it retains its properties under abrupt changes in environmental conditions and practically does not respond to external damaging factors.

The glue is contact, that is, the adhesion of the parts between themselves begins immediately after their contact. It is convenient to use, because you do not need to mix it with hardeners, the composition is ready for application. The glue line will be elastic, therefore, does not crack from movement and is suitable for vibration-prone, dynamic loads of products. Other characteristics of glue:

- flat, smooth surface, which after drying has no color, is suitable even for transparent, colored materials;

- inertness to the influence of aggressive chemicals: weak acids, alkalis, gasoline, petroleum products, oils;

- frost resistance, heat resistance, the possibility of operating products with an adhesive joint at -50 ... + 120 degrees;

- moisture resistance, suitability for use indoors, in the air, in open places exposed to rain, with high humidity.

to contents ↑UR-600 glue is produced in a very convenient container, so you can always choose the right amount for home use (750-1000 ml) and for industrial use (up to 20 l).

Adhesive Tips

The instructions indicate that in the rooms where work with the UR-600 is performed, it is necessary to organize good ventilation. To protect your hands, you can use gloves or apply IER-1 paste on the skin, which forms a strong film. When all actions with the product are completed, hands should be washed with soap in the usual way.

Glue should be stored in a closed container at + 10 ... + 25 degrees, excluding light, away from heaters, sources of fire, protecting from access of children, animals. Sunlight and moisture should not come into contact with this product, even if the container is tightly packed. Sometimes, if stored improperly, the glue crystallizes. It is not necessary to throw it away, just lower the container into water with a temperature of +70 degrees, and then mix the composition.

to contents ↑Technology use

According to the instructions, first you need to prepare the base. To do this, remove all dirt, dust, clean old coatings, rust, scale using any convenient means: sandpaper on a bar, sanding machine, spatulas. Next, both parts to be glued are degreased with any solvent, and dried thoroughly. Rubber, leather, leatherette are sanded to improve adhesion.

For work with glue brushes with limiters are well suited. Application is possible in two ways (optional):

- Cold. Grease the glued surfaces with UR-600 glue, making an even thin layer. Leave for 10 minutes, apply glue again in the same way, wait another 10 minutes. Then they press the parts against each other, hold for 2 minutes, as a result a strong seam is created. You can use the item in a day.

- Hot. Apply glue on the surface, leave them in the air for half an hour. Both bases are heated to +80 degrees with a building hair dryer or other devices, put together, pressed with a press for 3 minutes. Typically, the method is used for large areas. The product can be operated after 4 hours.

After drying, the strength of the adhesive joint will be approximately the same regardless of the method used, but the cold method leads to a much higher glue consumption (2 times).

to contents ↑Reviews on glue UR-600

On the Internet there are many reviews of this glue from users who have tried it:

“The glue is very reminiscent of cold welding in properties. When gluing PVC, it literally dissolves the surfaces of parts, welds together all layers of the structure. Gluing large products is rather inconvenient; it is very difficult to correct them. But the glue seizes tightly, if removed, then only cut with a knife. "

“I tried a lot of polyurethane adhesives, all were good, but they have a minus - the operating temperature is up to +70 degrees. Therefore, with the need for heating, it is better to use UR-600. It has excellent water resistance, the composition is ideal for gluing boats that can be constantly kept in water, taken out to dry in the sun, the seam will still not be destroyed. ”

“UR-600 glue can be easily diluted if it thickens, for example, add a little acetone, while the other compounds in the tubes will have to be discarded. Even with poor surface degreasing, gluing will still be reliable: the seam will not crawl, it will not collapse over time. This glue can be trusted 100%. "