Underfloor heating systems play an important role in the home heating process. Heating batteries often often does not affect the temperature of the floor, especially if it is decorated with ceramic tiles. This material even at + 25 ... + 30 degrees of air in the house has a cold surface, which is very unpleasant.

- Why do I need special glue

- What is glue suitable for?

- Types of floors

- Electric floors

- Water floors

- Infrared floors

- Classification of materials by composition

- One-component adhesives

- Two-component

- Cement based

- Characteristics of adhesives

- Criteria for choosing tile adhesive for underfloor heating

- Tile Laying Technology

- Necessary glue thickness

- Grout for underfloor heating

- Errors in laying tiles on a heated floor

- Temperature seams

- Wrong glue choice

- Defective tile

- Dry glue remained in the open bag

- Glue on the crests dried up

- Advancing Unfrozen Adhesive

- Popular brands of tile adhesive and manufacturers

- Ceresit

- Bergauf

- Knauf

- Litokol

- Unis

- "Prospectors"

This problem is easily solved with the installation of heated floors, which can be installed independently. To do this, you need a special tile adhesive for a warm floor, adapted to temperature extremes.

to contents ↑Why do I need special glue

During operation, the warm floor causes heating of all elements of the floor covering. Materials expand during heating and contract after cooling. The adhesive composition on which tiles or porcelain tiles are laid behaves similarly. That is why ordinary glue for mounting a warm floor is not suitable: it quickly cracks due to low elasticity during regular heating and cooling.

With one-time strong heating, a simple glue can completely separate from the surface and crumble. Damage to the adhesive composition entails the accumulation of air in the cracks, due to which thermal conductivity is reduced.

How to avoid these problems? It is necessary to choose specialized tile compositions that can easily withstand temperature extremes within -30 ... +100 degrees. They have high elasticity, reliably fasten any material of the rough foundation (concrete, wood) with decoration, do not change the thermal conductivity of the whole structure. Glues are dry mixes that need to be diluted correctly before use, or ready-made cans.

to contents ↑What is glue suitable for?

Flexible heat-resistant adhesive can be used in most varieties of underfloor heating systems by direct application to heating elements. However, film (infrared) type floors require the use of leveling mixtures before gluing. Otherwise, there is a risk of destruction of the elements of the system, which will quickly fail. When buying glue, you need to make sure that it is suitable for a particular type of system, which is always indicated on the package.

to contents ↑Types of floors

There are three types of heated floors: water, electric, infrared. They differ in the principle of operation and characteristics.

Electric floors

This kind of flooring is widespread. When installing the system, a single-core or two-core ultra-thin cable is installed directly under the tile. The advantage of the floor is the ability to install it on an old screed. Nevertheless, it should be smooth, without drops, and also have a sufficient height (4-5 cm), otherwise the system will not last long.

to contents ↑Water floors

In this system, heating is carried out by circulating hot water in the pipes. During installation, the warm floor is brought to the central heating system, so in the future it practically does not cause maintenance costs. Over time, the system tubes may become clogged due to deposits, so it is best to immediately install a filter device to prevent clogging.

to contents ↑Infrared floors

In appearance, such floors are a polymer film in the form of modules 50 * 50 cm. Heating elements are located inside each module. Infrared floors are very economical in terms of energy costs. The downside is only a decrease in efficiency when laying under ceramic tiles, porcelain tiles: infrared radiation from under these materials does not come out well.

to contents ↑Classification of materials by composition

In construction stores, there are three types of adhesive mixtures that are suitable for underfloor heating systems. They are classified according to the main component. All adhesives necessarily contain plasticizers that enhance elasticity and help maintain adhesive properties during expansion and contraction.

One-component adhesives

Polymeric one-component compositions are sold in finished form, they are packaged in plastic cans, buckets, are a thick paste. The adhesives contain synthetic resins, modifiers. Glues have a rather long pot life, so they are well suited for beginners. The downside is the high price.

Two-component

Two-component adhesives are made on the basis of polyurethane or epoxy resin. Both substances gain hardness only after the introduction of a hardener, which starts the polymerization reaction. Therefore, when laying a warm floor, you need to knead a small batch of glue at a time in order to have time to use it. Epoxy adhesives are more expensive than polyurethane adhesives, but both types of products are characterized by a high degree of adhesion and good elasticity.

to contents ↑Cement based

Glues based on cement, fine sand, modifiers are considered the most popular when installing underfloor heating. They are a dry mixture, which must be diluted with water before use. The cement hardening time is low, so you need to try to work faster or to breed small batches of glue.

Characteristics of adhesives

Before buying, you need to carefully read the data on the packaging of a particular product. Glue must meet a number of characteristics, otherwise it will not be suitable for underfloor heating systems:

- resistance to temperature changes (not less than -30 ... + 100 degrees), including up to critical temperatures;

- adhesion from 0.5-1 MPa;

- compatibility with coating material and base;

- high elasticity;

- ease of application.

Criteria for choosing tile adhesive for underfloor heating

When choosing glue for tile installation, it is necessary to take into account the type of facing material. Good glue is resistant to slipping of large tiles and very heavy elements. On tiles, porcelain stoneware, marble, no spots should remain and efflorescences appear during the operation of a warm floor.

If the product will be used in the bathroom, it must be resistant to high humidity, contain antifungal components.

For outdoor work, special compositions are used for anti-icing systems, which additionally have frost resistance.If there is a need for leveling the base, self-leveling mixtures with heat-resistant properties and sufficient elasticity are used. Also, when buying glue, you should take into account the manufacturers rating and purchase only a trusted brand, which boasts excellent quality.

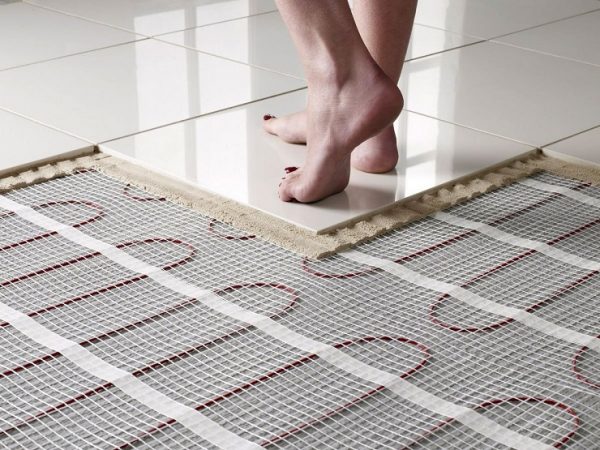

to contents ↑Tile Laying Technology

It is most easy to mount the floor when its heating elements are made in the form of flooring mats. In this case, it is not necessary to perform a screed on top of the system, which is necessary in all other options. When laying tiles on mats, you need to give them additional rigidity and close the cables, with which glue successfully copes. After the glue dries, they start laying the tiles.

If you have to install a concrete screed, durable cement or special self-leveling mixtures are used for this purpose. According to the norms for laying tiles, the height differences should not be more than 2 mm for every 2 meters of the finished screed. After pouring, wait until the screed is completely dry (from a week to 2 months, depending on the thickness). Next, you can start laying tiles:

- clean the surface, remove all debris, dirt from it;

- apply glue to the surface with a notched trowel, level it, forming grooves;

- lay the tile in 10-15 minutes to adjust its position.

It is not necessary to lubricate a large floor area with glue at one time, usually applying a tool per 1 square meter is enough to have time to stick the tile. When facing, it is necessary to observe technological seams that will not allow the material to deform and will help to avoid damage during expansion during heating. Usually, crosses are used when laying, which, after completing work, are removed. The seams are overwritten a day after the floor is lined, and they only begin to operate after waiting for the glue to completely dry (5-30 days).

to contents ↑

Necessary glue thickness

The thickness of the adhesive layer can be different and is calculated depending on the instructions of the manufacturer of the underfloor heating system. Most often it is recommended to make a layer of 3-5 mm, which is easily done with a notched trowel with a tooth height of 1 cm.

If the system is used in the form of mats, first it is fixed with a minimum amount of glue, and then a spatula with teeth of 0.8 cm is used. For large plates, a layer of at least 6-7 mm is made, and glue is applied both to the floor and to the back of the tile .

to contents ↑Since heat-resistant adhesives have good insulating properties, do not exceed the recommended thickness of the product - this will reduce the quality of floor heating.

Grout for underfloor heating

It is advisable to purchase a grout of the same manufacturer as the glue. It should also be flexible, easily withstand temperature extremes. Color is selected in harmony with the main tone of the tile. The joints between the wall and the floor are sealed with silicone compounds that are not subject to cracking. It is forbidden to use simple cement-sand mixtures for mashing joints that do not meet the requirements of using underfloor heating systems.

to contents ↑Errors in laying tiles on a heated floor

To improve the quality of the finished coating, you must follow the advice of specialists and eliminate common mistakes.

Temperature seams

Seams compensate for the linear expansion of the floor base during heating and cooling. The grout shrinks under the influence of physical factors, and the tile in the area of the damper seam (between the wall and the floor) can separate, because the vibrations sometimes amount to several millimeters. Even the most elastic material is not able to smooth out such a drawback, so tilers use special techniques.

To seal the damper seam, you can use a special layout of the tile so that only the edges fall on the joint, but this negatively affects the overall layout of the coating. It is also possible to seal joints only with silicone sealant, but it often differs in color from the main grout. It is better to smear part of the tile directly above the damper seam with glue, and treat the rest of the material with sealant, as a result, the correct layout of the plates will not be violated.

to contents ↑Wrong glue choice

Manufacturers also produce the so-called "universal" adhesives, which can be used on most substrates: from concrete, OSB-boards to drywall and underfloor heating. Most often, the adhesion of such compositions is lower than that of specialized mixtures that are designed for a specific building material. It is better to choose a really suitable glue, which is especially important when laying smooth porcelain stoneware.

Defective tile

In stores, marriage of tiles is not common, but sometimes you can get it. Deviations in shape and thickness of porcelain stoneware usually occur. Detecting trouble before gluing the plates will immediately fix the situation by increasing the thickness of the glue and applying the correct layout. If the tile is curved, it is better not to use it at all. Custom-sized elements are most reliable to glue with a herringbone layout.

to contents ↑Dry glue remained in the open bag

All tile adhesives are quite hygroscopic, but it is possible to keep them even in open form for 14-20 days. To do this, it is necessary to carefully remove air from the bag, wrap the packaging with a plastic bag in several layers. Store the bag in a room with low humidity and temperature. After 1-2 months, the adhesive will still have to be thrown away if it remains unclaimed.

to contents ↑Glue on the crests dried up

Do not lay tiles on dried glue, which is not able to provide a sufficient level of adhesion. You just need to take a notched trowel, a couple of times to hold them on the glue and apply a little fresh means. Excess should be removed from the tile.

Advancing Unfrozen Adhesive

It is impossible to allow walking on an incompletely dried coating. If this happens, remove the tile from the floor surface. To avoid damage to neighboring elements, an OSB plate or board should be placed on the floor, which will increase the stop area and help prevent further displacement of the plates. After that you need to remove the shifted element, clear of glue and repeat laying again.

Popular brands of tile adhesive and manufacturers

Builders prefer to use proven adhesives brands Axton, Bergauf, Ceresit, "Litokol" and others. Below are the most popular tools.

Ceresit

The manufacturer of products under the brand name Ceresit is the German company Henkel, which has long been highly trusted by craftsmen. All products are manufactured taking into account environmental standards, it does not contain harmful components, so it can be used indoors and does not give fumes after heating.

For tiles, the following adhesives can be used:

- CM16;

- CM117;

- CM17;

- CM14 EXTRA.

The last specified glue is used most often. It allows you to work at temperatures of + 5 ... + 30 degrees, has large periods of mortality and tile adjustment (2 hours and 20 minutes, respectively). Glue adhesion level - 0.8 MPa, operating temperature - from -30 to +70 degrees. A day after laying, you can start grouting the joints on the tile.

to contents ↑Bergauf

Bergauf mortar mixes are of excellent quality. They are produced by the German-Russian company of the same name and include a whole line of tools for working with tiles. For underfloor heating, Keramik Express is usually used - a quick-drying adhesive that cures in 4 hours.

It is necessary to work with glue quickly: a portion retains its properties for 45 minutes, the time for adjustment, equal to only 10 minutes. The product can withstand heating up to +70 degrees and cooling to -10 degrees. Typically, the adhesive is applied on cement, concrete screed, including in the bathroom.

to contents ↑Knauf

Glues of this brand are also produced in Germany. The best tool for underfloor heating is Knauf Flex - a dry cement mixture with high adhesion and elasticity. It can be used to easily lay tiles even on gypsum fiber and old ceramics.The glue has good performance in terms of use temperature (-30 ... + 80 degrees) and adhesion (1 MPa).

to contents ↑The tool has excellent water resistance, even beginners can work with it, because the life time of the solution is 3 hours. The glue dries in two days, after this time you can grout the joints. Before installing the underfloor heating, it is imperative to apply Knauf Flachendicht primer to the base.

Litokol

Glues of the Litokol brand are made in Russia. For a warm floor, you can buy Litoflex K80, which is a dry, finely dispersed cement mixture. The glue is distinguished by the highest time for adjusting the position of the elements - 1 hour, because beginners prefer to buy it. It can withstand temperatures up to +90 degrees, which is ideal for underfloor heating systems.

In the range of tiled products of this company there is another one suitable for underfloor heating. This is Litoelastic, a two-component polymer composition that mixes right before work. It dries during the day, gives only 45 minutes to adjust the tiles, but can withstand temperatures of -40 ... + 100 degrees and has a very high elasticity.

to contents ↑Unis

The Russian manufacturer Unis produces Unis Plus adhesive, which is perfect for underfloor heating systems. It has one of the highest adhesion rates - 1.25 MPa, it is considered an environmentally friendly product, therefore it is widely used in child care facilities. The solution can be applied within 3 hours, but only 10 minutes are given to fix flaws in the position of the tile. The adhesive can withstand operating temperatures of -50 ... + 70 degrees. You can walk on the finished surface after 24 hours. Due to the high adhesion, it is not recommended to use glue on deformable substrates.

to contents ↑"Prospectors"

The "Prospectors" company (Russia) produces high-quality tile adhesive "Prospectors Plus", which allows laying any tile on warm floors. Glue is intended only for non-deformable substrates (concrete, cement). You can work with a portion of the solution for 4 hours, the time for adjusting the tile is 15 minutes. The adhesion of the composition is 0.5 MPa, which is sufficient for flooring. This tool is characterized by good elasticity, and at the same time has a favorable price, therefore it is respected by specialists.