Parquet is not cheap, but very beautiful and high-quality flooring. You can lay the material with your own hands if you know the technology and purchase a high-quality tool for gluing. Glue for parquet can be unequal in composition, price, most importantly - it must meet the specified characteristics.

- Parquet adhesive requirements

- Overview of formulations and their use

- Dispersion adhesive

- Solvent glue

- Two-component adhesive

- One component adhesive

- Popular brand brands

- The choice of glue depending on the coating

- Instructions for gluing parquet

Parquet adhesive requirements

Not all adhesive products sold in construction stores are suitable for laying a new parquet floor. Their components are required to securely fasten the lamellas, while not causing damage to the material. A good adhesive meets the following requirements:

- No shrinkage. After the final drying, the adhesive layer retains volume, otherwise the boards will move, creak after laying on a concrete screed or plywood.

- Durability. A conscientious adhesive manufacturer guarantees a long service life, especially since the parquet floor itself does not lose its properties and attractiveness for more than a hundred years.

- Elasticity. This quality allows the product not to tightly glue the parquet, but to make it moderately mobile - within the limits of displacement during temperature changes. Only elastic glue will not crumble with temperature changes.

- No harm, unpleasant odor. Some products are environmentally friendly, others contain solvents. After drying, the latter completely evaporate and do not harm a person.

The adhesive composition should not have much water, otherwise the wood will swell, be damaged. For this reason, ordinary glue, such as PVA, is not suitable for laying. Unsuitable glue reduces the attractiveness of the coating and reduces its operating time.

to contents ↑Overview of formulations and their use

Laying on a concrete or other base when flooring can be glued and “floating”. It is the first technique that is recommended - it gives a better result. Several varieties of adhesive compositions are available. Therefore, in the store you can find the following types of glue:

- two-component;

- single component;

- water dispersion;

- synthetic - with solvents.

to contents ↑What to choose when performing repairs? Each option is used in the practice of installing parquet, but has its own characteristics. The choice depends on the type and type of wood, on the type of base on which the boards have to be glued.

Dispersion adhesive

Water glue, it would seem, is not suitable for parquet, because such compositions can soak the material. But they produce special "parquet" dispersion adhesives suitable for repair. Best of all they fix lamellas from larch and oak, these types of wood are highly resistant to water, they are the most durable. Such a composition is also suitable for small piece parquet.

You should not use such tools when working with wood fruit trees - apple trees, cherries, pears. Maple, beech, and alder are also considered unstable to moisture: wood will quickly begin to rot, deform, and collapse.You can not use such adhesive solutions with a small thickness of the boards and in the presence of more than 30% of the water in the composition.

Advantages of dispersion-based adhesives:

- safety for the body, the ability to use even in the children's room, 100% environmental friendliness;

- the exclusion of allergic reactions in humans;

- lack of an unpleasant smell;

- simple and convenient application;

- a large assortment;

- moderate cost per kilogram (from 200-300 rubles).

Solvent glue

A more reliable and safe option for the material itself is a synthetic solvent-based adhesive. Experienced SUVs choose such compounds more often than others, because they are suitable for any species of wood, do not cause swelling and decay. Means may contain rubber, rubber, and other substances.

A distinctive feature is the high strength of the binder components, compatibility with most substrates (plywood, concrete, etc.). Other advantages:

- simple work, convenient application;

- the ability to not cover the glue - the jar is open for up to 15 minutes;

- stacked lamellas can be corrected, change position.

The disadvantages include a long period of complete drying - up to 5 days, so it is better not to live in the repaired room or at least close the room tightly. For work, a full set of protective equipment is necessarily used: a respirator, tight clothing, gloves. Significant disadvantages are flammability, explosiveness, installation should be done with great care, strictly eliminate smoking. The price of adhesives with solvents is much higher than dispersion compositions.

to contents ↑Two-component adhesive

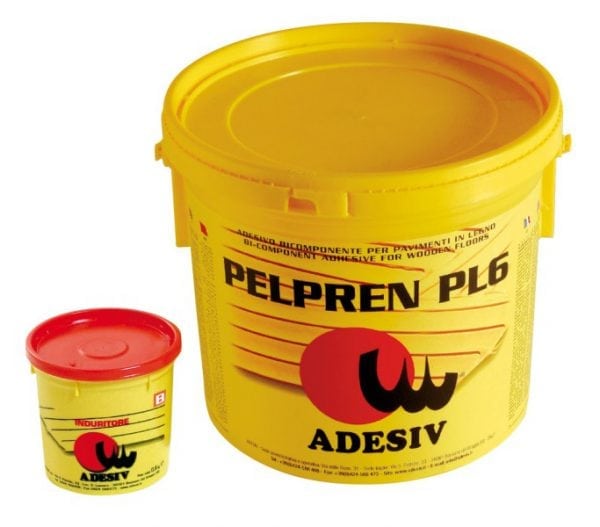

Reactive (two-component) glue is a popular choice of specialists. With the help of tools, parquet can be glued to concrete, plywood, metal, other substrates. The compositions are sold in buckets in a dry form. To obtain the finished mass, the powder is diluted with the attached emulsion, then mixed and wait for the time specified in the instructions.

The two-component solution is considered the most durable for parquet among all other compositions. Adhesive strength is ensured by the presence of a hardener, while there is no water or solvents in the product. The final hardening will take from 2 to 3 days, but some funds are set in a day. Reactive glue is used for any kind of floorboard. It does not harm even the most delicate wood, expensive art parquet, glues a massive board well.

Adhesives also have flaws. Their price is very high, although this is justified by the long life of the floor in the future. Another disadvantage is the toxicity of the drugs, until they finally harden, they continue to emit harmful substances. Work with adhesives only in respirators, but after full hardening, they are not dangerous even for children. Also, one should not forget about tight gloves during the installation of parquet: contact with glue on the skin can cause a burn.

to contents ↑One component adhesive

These funds are ready-made mixtures based on synthetic components. The most famous adhesives are silane and polyurethane PU based on silane and polyurethane, respectively. The most popular polyurethane composition for parquet, they can glue lamellas of any size and type of wood. Means are best suited for mounting wood on a concrete base, they are often used even in factory production. Hardening takes place in 4-5 days, and all this time the composition releases harmful fumes. But glues have undeniable advantages - they are economical in price and do not shrink.

to contents ↑Popular brand brands

On sale you can find a large number of adhesive compositions that are allowed to be used when installing a parquet board:

- Kiilto Standard. Finnish dispersion product suitable only for oak and larch, as it contains 35% water. Differs in low expense - only 600 g / sq. m

- UZIN MK 73. Contains synthetic resins and solvents, suitable for laying any kind of parquet on all types of substrates. It can be used on underfloor heating.

- Bostik Tarbicol KP5 is a water-dispersion solution, most often used for fastening moisture-proof plywood under parquet. It has a low price. Includes vinyl components, can be used on heated floors.

- Artelit RB 110. It is a professional rubber adhesive on solvents for plywood, parquet, wooden mosaic. Highly elastic composition, very durable, suitable for any kind of wood.

- Kiilto Flex Silan. Silane one-component adhesive, can be used on a board with a varnish, oil coating, helps to mount plywood and solid wood. The product dries only a day.

- BONA B-720. A dispersion solution with a low water content (22%), suitable for substrates made of moisture-proof plywood and parquet from oak and larch.

- SikaBond-95. Sikabond-95 glue-sealant - a rigidly elastic composition for fixing piece and modular parquet, plywood, OSB-boards. It is a one-component tool with high grip quality. Sika also manufactures Sikaflex-290 for sealing joints and simulating decking.

- Axton 2k. It is sold in cans of 14 kg each, is a dispersion composition, suitable only for oak and larch, as well as for all types of laminate.

- Stauf-PUK 446. Represents a two-component means without pitches, is suitable for any types of a parquet, including art and large-format.

- Adesiv Pelpren PL6. Epoxy-polyurethane two-component composition, gives increased strength of the seam, while maintaining its elasticity.

- LiquiRock Also applies to polyurethane compounds, includes a base and hardener, does not harm even the most delicate types of wood.

The choice of glue depending on the coating

Knowing the types of adhesives and their main brands is not enough. It is also important to consider the specific appearance, dimensions of the lamellas, and material characteristics. There are a number of recommendations for using formulations depending on different types of flooring:

- Piece of ash, larch and oak uncoated, glued to plywood. If the lamellas have dimensions up to 420/70 mm, water-based products are allowed. The liquid in their composition will not be absorbed into stable rocks, deformation will not happen.

- Parquet from ash, oak, larch with factory coating, gluing on plywood. For this purpose, you need to buy a 1- or 2-component product based on polyurethane. Dispersion adhesives can cause warping and rapid appearance of defects.

- Varnished material. It is necessary to choose a tool that is most resistant to separation. Usually buy two-component compounds.

- Parquet uncoated from fruit species, as well as maple and beech. In order to avoid damage to unstable wood, it must be glued to a product with solvents or other compounds without the slightest water content.

- Massive glued board, glued to plywood. Lock-type large-format lamellas are glued with water-free means, with high elasticity. Otherwise, the adhesive layer will crumble.

- Massive board up to 120 mm, glued to plywood. Narrow - eliminates the use of dispersion funds, as it greatly moisturizes the material. High strength and elasticity are mandatory characteristics of the composition. If this type of flooring is glued to a cement screed, which is rarely practiced, you need to buy only polyurethane compounds with maximum tensile strength.

- Massive board over 120 mm, glued to plywood. With a large width of the lamellas, the main characteristic of the composition is the tensile strength. You need to buy one-component products on synthetic resins.

- Any type of parquet, glued to a weak cement screed. The tool should reliably adhere to the coating literally at the molecular level. Bicomponent solutions of high quality are purchased.

- Industrial flooring. Narrow vertical boards are used in buildings with increased traffic. Any two-component adhesive is suitable for their fastening.

Instructions for gluing parquet

The easiest way is to lay the material on a wooden base - waterproof plywood, OSB-plate. When attaching to a concrete screed, it is important that at least a month passes from the device of the latter.A layer of waterproofing is surely laid on the screed, which will also serve as a heater. It is also recommended to go through concrete with bitumen mastic, it will fulfill the role of a primer.

To install the flooring, you need to purchase a suitable glue, putty knife, punch, hammer, tape measure, hacksaw, wedges and tamping block. The number of boards is taken into account with a margin of 3-15%. Parquet should be brought into place 2 days before the start of work, let it mature, get used to the temperature in the room. The order of work will be as follows:

- Inspect the surface, measure with a level. Cracks, large drops fill with a building mixture. Small on plywood - remove with a grinder.

- Clean the floor of dirt, dust, debris.

- Apply soil using a roller, preferably 2 times. The soil should match the glue, ideally combined with it.

- Make a preliminary calculation of the boards, determine which of them need to be corrected. To draw and cut individual elements, number them.

- Prepare glue if it needs to be mixed.

- Gather the tool with a spatula, distribute on the floor with a thin layer to the width of two or three rows of boards.

- Put the first board, push it to the floor. After a minute, insert the second board into the groove of the first, lower it to the floor. Run 2-3 rows of coating. Each check level and tap with a hammer.

- Leave 10 mm between the wall and the parquet - a technological gap. To do this, put the bar in the slot.

- Upon completion of work with 2-3 layers, wipe the glue out. Repeat the installation of the remaining coating.

If necessary, after the adhesive has completely hardened, you can polish the parquet board. Within 3-5 days it is impossible to turn on the floor heating, walk on it, do through ventilation. It will be better to press the boards with the load - this will help to more reliably fix the new floor covering.