Epoxy resins - a universal oligomeric material used for the production of compounds, composites, as well as for pouring various surfaces and the manufacture of glue, sealant. Due to the unique combination of beneficial properties, epoxy is useful both in industry and in everyday life. Of the entire variety of products, the ED-20 epoxy resin stands out - an inexpensive high-quality product.

- Properties of resin ED-20 and application

- Technical specifications

- Analogs of the material

- ED-8

- ED-16

- ED-22

- E-40

- Instructions for use ED-20

- Resin preparation

- Use of plasticizer

- DBF plasticizer

- Plasticizers DEG 1 and TEG 1

- Use of hardener

- PEPA, THETA and DETA

- ETAL 45M

- Epoxy Viability

- Different bonding quality

- Packaging, storage and transportation

- Safety ED-20

Properties of resin ED-20 and application

Epoxy-diane resin ED-20 is a transparent viscous liquid of yellow, brownish color without mechanical impurities, inclusions. It is a fusible reactive product based on diphenylolpropane and epichlorohydrin. The manufacturer of the resin of this brand - FKP Plant them. Sverdlova, it also produces a number of other companies. The average mass fraction of epoxy groups in the resin is 20%, hence the designation of the material.

ED-20 is combined with different hardeners, in some cases, the addition of plasticizers is required (to reduce the rigidity of the finished product). Curing is possible cold and hot (at room or elevated temperature), this process does not require press and thermal equipment. The properties of ED-20 are as follows:

- high density, porosity of the finished product;

- excellent hardness, resistance to mechanical damage, aggressive environment, moisture;

- heat resistance;

- dielectric and anticorrosive abilities;

- good adhesion with plastic, metal, glass, ceramics, wood, Kevlar, carbon fiber and many other materials;

- ease in work;

- low shrinkage, low specific gravity.

Epoxy is widely used in various sectors of the economy. It is used for the repair of electrical equipment, computers, electronics, parts and hulls of yachts, boats, boats, for the manufacture of furniture - tables, chairs.

With the help of ED-20 they make beautiful countertops, haberdashery, and bathroom products. The material is well suited for construction, mechanical engineering, aviation industry, instrument making. Its use for covering walls, creating bulk floors helps in the most daring design decisions.

ED-20 is a part of various paints and varnishes - primers, impregnating varnishes, enamels, pouring mixes. On the basis of epoxy make reinforced plastic, fiberglass, fiberglass.

to contents ↑Technical specifications

The epoxy gelatinization time is 8 hours and the full cure period is 24 hours. The following technical specifications are indicated in the description of the highest grade of material:

- density during cold curing - 1110–1230 kg m3, with hot curing - 1200–1270;

- mass fraction of chlorine ions - 0.001%, saponified chlorine - 0.3%;

- mass fraction of hydroxyl groups - 1.7%, volatiles - 0.2%;

- dynamic viscosity - 13–20 PA / s;

- temperature regime for softening - up to 60 degrees.

Analogs of the material

According to the constituent components, properties and applications, there are a number of similar epoxy resins from the ED, TEG, KDA groups. If necessary, they can replace the ED-20. Below are the most famous resins.

ED-8

Epoxy ED-8 is produced according to GOST 10587-84. It is a soluble fusible oligomeric product of the same substances as ED-20 (diphenylolpropane and epichlorohydrin). Resin is widely used in the aviation, shipbuilding, engineering industries, in the manufacture of paints and varnishes, at a construction site, in the repair of equipment, electronics. Epoxy also serves as a bonding component for reinforced plastic.

According to the physicochemical parameters, ED-8 also differs little from ED-20. The content of chlorine ions and saponified chlorine is similar, but no hydroxyl groups are found in the mass. Viscosity and softening point are the same. The main difference is in the mass fraction of epoxy groups (8%) and gelation time (3 hours).

to contents ↑ED-16

The epoxy resin ED-16 has the same properties and uses, but includes a different number of epoxy groups - about 16%. The viscosity of the product is less than that of ED-20, therefore, gelation occurs faster (approximately 4 hours). The tool is characterized by high strength characteristics of the adhesive joint, but it has a higher amount of chlorine.

to contents ↑ED-22

Another epoxy based on epichlorohydrin and diphenylolpropane, the proportion of epoxy groups is 22%. Resin ED-22 among the features has a higher gelation time of 18 hours, with a dynamic viscosity of 8-12 PA / second.

E-40

The manufacturing technology of epoxy E-40 is somewhat different from the creation of materials brand ED. The product is obtained by condensation of epichlorohydrin and diphenylolpropane in an alkaline medium with the addition of a toluene solvent. The tool can be brought into a non-melting state by using hardeners - polycarboxylic acids, their anhydrides, polyamines.

The scope of the material is the preparation of enamels with high protective properties, as well as the creation of varnishes and putties. In addition, the E-40 acts as a semi-finished product for the manufacture of other epoxies, adhesives and compounds for pouring. The resin has high plasticity, moisture resistance, in the polymerized form does not react to the action of moderately aggressive acids, alkalis.

to contents ↑Instructions for use ED-20

The result of mixing the resin and hardener will greatly depend on their proportion, environmental conditions, quality of preparation of containers and a number of individual factors. Instructions for use are not always step-by-step, it usually indicates only the exact ratio of the components and the basic requirements for the polymerization process. It is recommended that you first buy the liquid hardener specified by the manufacturer (if it is not included in the kit) and mix it with the resin in the lowest possible dosages. This will allow you to see the result and draw conclusions about the correct proportions.

Mixing resin in small volumes is not difficult. For this purpose, cold curing technology is ideal when all work is carried out at room temperature. Before mixing epoxy in a large volume, it will be necessary to prepare dishes for heating the resin, since the method of hot curing is used. The epoxy is heated in a water bath to a temperature of 50–55 degrees, after which further work is carried out in accelerated mode.

to contents ↑It is important to consider that after the hardener is added, the polymerization reaction is irreversible, it cannot be stopped, there is a chance to only slow down a little by lowering the ambient temperature. Incorrectly performed actions will lead to spoilage of a portion of epoxy, so all calculations must be made in advance.

Resin preparation

No special material preparation is required for cold curing. For a hot method and acceleration of impregnation (pouring), it is recommended to heat a measured portion of the product. To do this, install a water bath, place on it a container with epoxy resin. It is important to ensure that not a drop of water penetrates the mass, this will ruin it.Also, you can not overheat the material, the reaction will go too quickly, and bringing to a boil will lead the resin to disrepair. It will be optimal to heat up to 55 degrees or less. You can completely lower the container with the material in the dishes with hot water, let stand without boiling water. Stir the mixture periodically for uniform heating.

to contents ↑When stored or exceeded, the epoxy can crystallize. You need to make sure that it does not have crystals, turbidity, otherwise it is heated to +40 degrees with vigorous stirring. This will help restore transparency to the material.

Use of plasticizer

Adding a number of components will help plasticize the epoxy. Why is this needed? If the product in the future must withstand high shock or other mechanical loads, the breaking force using a lever, its elasticity must be increased. The addition of special plasticizers allows to partially extinguish such loads. Also, their introduction is recommended to enhance the elasticity of the joints, if the epoxy is used for bonding and pouring.

to contents ↑DBF plasticizer

Dibutyl phthalate, or DBP, is the most popular plasticizer for epoxy, it is added in small quantities - up to 2–5% of the total volume. The tool is able to protect products from cracking during frost, shock. DBP is especially indicated when using PEPA and TETA hardeners. If the hardener Etal 45M is used, the addition of a plasticizer is not required. A disadvantage of DBP can be called a complex compound with a resin, so it is necessary to apply long mixing with heating.

to contents ↑Plasticizers DEG 1 and TEG 1

Diethylene glycol, or DEG 1, is itself an epoxy, and is suitable for diluting the bulk as a plasticizer. The working concentration for ED-20 is 3–10% - the more funds are added, the more the resin will resemble rubber. DEG-1 easily connects with epoxy, it is much easier to use if colorless is not important. Due to the orange tint, this plasticizer is not suitable in every case.

TEG 1 in properties and application is similar to DEG 1, but slightly more viscous in consistency, has a brown or yellow color. The main difference in the composition is that instead of diethylene glycol, TEG 1 contains triethylene glycol.

to contents ↑Use of hardener

Hardener is a full-fledged participant in the chemical reaction of the polymerization of epoxy resin. It is introduced into the mass after the addition of plasticizers. To reduce the risk of epoxy boiling, its temperature at the time of mixing with the hardener should be no more than 30–40 degrees.

Usually 1 part of hardener is introduced per 10 parts of resin, but the proportions will depend on the needs, such as the finished product. In some cases, a 20: 1 ratio is sufficient, and sometimes, on the contrary, 5: 1 is required. The hardener is added to the bulk very slowly, since starting a thermal reaction can cause overheating and damage to the resin. A rapid infusion usually causes an avalanche-like process, when the mass overheats and freezes instantly. Too much hardener and high initial epoxy temperature can lead to the same consequences.

to contents ↑PEPA, THETA and DETA

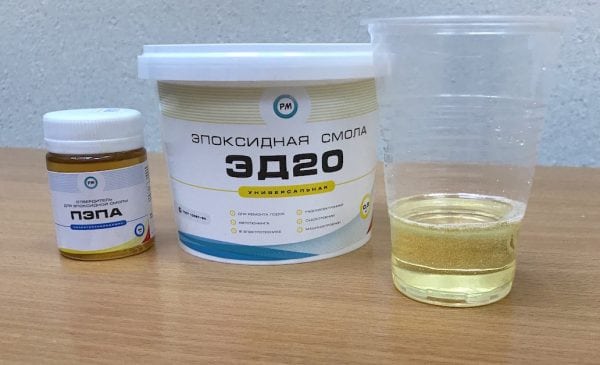

Polyethylene polyamine, or PEPA, is an inexpensive and very popular hardener, it works at room or low temperature, does not require heating of the initial mass. PEPA does not reduce its properties even at high humidity. It has a yellow, brown color, sometimes a little greenish, based on it - ethylene amines. The optimal amount to add to the epoxy is 13.7%, it is important to enter the range of 10-15%.

TETA triethylenetetramine is another well-known traditional hardener that allows the preparation of resin at temperatures of + 15 ... + 25 degrees.By cons include pungent odor, toxicity of the substance. It requires the strictest proportions (for PEPA, this is not so important).

The hardener DETA belongs to the same group of substances for the cold polymerization of epoxy resins. A distinctive feature is the seizure of moisture and carbon from the air, so it must be stored tightly closed. The tool cures the resin in 1.5 hours.

to contents ↑ETAL 45M

This universal hardener has a "predetermined ductility", therefore, does not require the introduction of plasticizers. Its consistency is close to the ED-20 resin itself, mixing will be easy. The temperature reaction from the addition of Etal 45M is less violent, moreover, it is not toxic, does not cause allergies, without an unpleasant odor.

to contents ↑Epoxy Viability

The life time is the period of time in which the liquid or viscous state of the mass remains after the introduction of the hardener. During this period, epoxy is suitable for use. Different resins have different viability, as well as hardeners. Usually this figure is 30-60 minutes.

to contents ↑When PEPA is added to ED-20, the lifetime is 30–50 minutes and depends on temperature and the amount of hardener. Full polymerization lasts from 24 hours to several days. For Etal 45M, the viability is 3 times greater, and the full polymerization is the same, which is convenient for the master.

Different bonding quality

The quality of epoxy can vary depending on the brand of hardener, plasticizer. The more expensive and effective additives are used, the more the finished product will meet the requirements. Therefore, do not save and buy the cheapest fillers.

Packaging, storage and transportation

Epoxy resin is packaged in containers of 50–220 kg (drums), as well as in cans, plastic containers from 0.5 kg and more. Transport means on the covered transport. Storage of material is allowed at a temperature of + 15 ... + 40 degrees, tightly closed, away from sunlight. Do not store it near acids and oxidizing agents.

Safety ED-20

Work with this tool should be carried out in a well-ventilated area or in the presence of good ventilation. For protection, a respirator, goggles, gloves, tight clothing or an apron should be used. ED-20 is not explosive, but burns when it enters a fire.

The degree of danger of the resin is characteristic of substances of the 2nd class of exposure to the human body. In case of skin contact, allergic reactions, dermatitis often occur. The affected area should be washed with soap, rubbed with alcohol, then greased with petroleum jelly, castor oil.

Thanks . Everything about resins and hardeners is clear.

The question? I bought the resin ed-20 hardener pepa, mixed 100: 10g. for testing at a temperature of +20 and filled the picture from 3mm-fiberboard, a day passed ... the surface is sticky to the touch ... how to avoid this or what it happened from or it still dries ..

Thanks.

Good afternoon.

It happens. The duration of curing is affected by: thorough mixing (at least 2-3 minutes); room temperature and humidity (at a low temperature and high humidity - slower); thickness of the cured surface (the thinner the layer, the slower the curing).

Ed20 with pen hardener are mixed 1:10 in volumetric rather than weight proportions. On eye 1: and is checked by a warming match on a piece of paper. It should boil a little and harden. Then it needs to be broken. If little hardener bends. If it breaks, then the norms. If a lot of hardener crumbles

I do not agree a bit in proportion. In my case, the mixture ED-20 + PEPA in a volume ratio of 10: 1 did not harden. But in a weight ratio of 10: 1, which gives a volume of about 8: 1 - hardens with a good result. It is necessary to try on small volumes.

Good afternoon. The correct ratio for curing, by weight: 10/1 = ED-20 resin / PEPA hardener.

For ed-16, ed-20 is a hardener of hot rejection?

Good afternoon.

There is maleic anhydride.

Suitable for use in the manufacture of jewelry? The girlfriend at work of this resin has a whole warehouse. )))

I just started trying, but for Artline’s “experiments”, buying expensive is a pleasure. At least for the first time to practice, are my pendants and key chains too dangerous?

Good afternoon.

As a specialist working in the production of epoxy resins, I want to say that there are significant inaccuracies in the description of the quality indicators of epoxy resins in the article.

According to GOST 10587-84, resin ED-20 is not an analogue of resins E-16 and ED-8. The higher the mass fraction of the epoxy groups, the less viscous the resin. Thus, if we compare the three grades of resins given in the article, the lowest viscosity resin is ED-20, and the most viscous, generally hard, is ED-8. Therefore, only the ED-8 resin has a softening point.