Epoxy is a material familiar to many. It appeared on the market more than 60 years ago and is still widely used in construction. The area of use applies to industry and households. Now there are many varieties of epoxy resins with unique characteristics and properties.

- Basic information

- Advantages of Epoxy Resins

- Properties and characteristics

- Resin Types

- Receipt and production

- Popular brands

- Application area

- Combining epoxy with other materials

- Hardeners for epoxy

- Epoxy Quality Standards

- Safety precautions

Basic information

What is epoxy resin? As described, this chemical is a synthetic oligomer containing epoxy groups. The latter, under the action of hardeners, are able to form crosslinked polymers. Epoxy, as they call it in everyday life, has a complex formula and is a condensation product of epichlorohydrin and bisphenol A.

In its pure form, an epoxy is not used, its use is justified only after the addition of a hardener and the polymerization that has occurred. There are different types of resins, their purpose differs depending on the properties. In turn, the properties depend on the composition of the material. What is the resin made of, what is included in it, other than epoxide? Upon receipt of the finished product in the recipe, different manufacturers can use the following components:

- powder fillers - alabaster, cement, chalk (up to 30-40% by quantity) are needed to seal the mass structure and give strength;

- microspheres - fine-grained balls in the form of powder, make the resin air due to the fact that their density is low;

- fiber (cotton, glass) - increases the viscosity of the finished resin, it becomes thick and perfectly fills all gaps, impregnates surfaces;

- natural wood chips - needed to reduce the specific gravity of the product;

- Aerosil - helps to avoid smudges of resin on vertical surfaces;

- graphite - required to give color, used as a black pigment;

- titanium dioxide, aluminum powder - also paint the transparent material in white and gray, respectively.

to contents ↑Adding such fillers allows, after curing the epoxy, to obtain high-quality plastic with desired properties. To reduce brittleness, plasticizers, for example, castor oil, are added to the raw material. Their share is usually determined experimentally.

Advantages of Epoxy Resins

Why is the material widely used in the construction industry? It has many advantages and advantages over other resins:

- resistance to abrasive substances, which reduces the rate of wear;

- high strength of the adhesive joint;

- excellent physicochemical characteristics;

- the lowest moisture permeability;

- lack of shrinkage or its small indicator during the operation of products.

Properties and characteristics

In appearance, pure epoxy without additives looks like a transparent yellowish, dark yellow or orange liquid, it is very similar to honey. Some types of resins are brown and resemble tar. Adding fillers can give the resin a different color - from white to red, black.

Epoxy almost does not react to the action of halogens and is destroyed only by the influence of strong acids. Most alkalis are also not capable of breaking molecular bonds. The tool has the highest adhesion to metals, but glue based on it is used to connect many other materials:

- wood;

- faience;

- ceramics;

- rubber;

- skin.

Depending on the type of epoxy, the resulting adhesive joint will be stiff or elastic. Technical features also vary. As an example, one of the most popular brands of epoxy is ED-20. Here are its characteristics:

- density - 1.16-1.25 kg m3;

- tensile strength - 40-90 MPa, bending - 80-140 MPa, compression - 100-200 MPa;

- temperature for polymerization - from +20 degrees, curing time - 1.5 hours;

- hardener volume - 5 parts per 1 part of resin;

- water absorption in 24 hours - not more than 0.01-0.1%;

- heat resistance + 55 ... + 170 degrees;

- impact strength - 5-25 kJ / sq. m

Resin Types

Any epoxy resin is two-component, it includes the main composition and hardener in two separate packages. Depending on the components of which the material is composed, it is divided into cold and hot cured resins. The last type of curing will be required if the final products are supposed to be used in aggressive conditions, under the influence of high temperatures, chemistry.

Also, all epoxy are divided into the following varieties:

- Epoxy Diane. Includes materials marked ED-20, ED-22, ED-16, ED-10, EP SM PRO. They can be used in everyday life, industry. They are well suited for the manufacture of bulk floors, impregnating compounds, the creation of adhesives and sealants. Of these resins make different types of plastic, protective coatings.

- Epoxy Diane for paints and varnishes. These are epoxies of grades E-40, E-40 R, they are involved in the production of varnishes, paints, and other coatings that are resistant to damage.

- Epoxy-modified - EPOFOM 1, 2, 3. They are part of epoxy compounds, participate in the repair of floors, pipelines.

- Epoxy resins for special purposes. They have special properties, which allows them to operate in extreme conditions. An example is the resin ECH (chlorine-containing), UP-637 (with resorcinol), EDA and many others.

Receipt and production

The material is produced in Russia, CIS countries, abroad. It was first obtained by the French chemist Castan, this happened in 1963. The tool can be made by polycondensation of epichlorohydrin with phenol or edible oils, for example, soy. This process is called "epoxidation." The most valuable grades of resins are obtained as a result of the catalytic oxidation of unsaturated compounds. This allows you to give the product higher strength properties, water resistance.

to contents ↑Since any resin is 2-component, a hardener (amine, anhydride, some acids) will be required for its dilution. Curing catalysts are often added to hardeners during the manufacturing process. After this, the resin solidifies, passes into an insoluble compound.

Popular brands

A huge number of resins from different manufacturers is being sold - Novol (Novol), Epoximax, Moment (Henkel), Khimprom, Chemical insulation, Mila Group, Ugrareaktiv, Epital, Ekovanna "," Leonardo "(resin for creativity) and many others. The following are the famous brands of epoxy:

- Bulk composition EPS 2106. Two-component painted product for finishing, leveling coatings on concrete or as an independent coating.

- “Art-Massive” and “ART-ECO”. Low-viscosity compounds based on modified resin and hardeners are used for coating wood, stone, metal. Allow you to make beautiful 3D floors.

- "Master" MK HT-116A. Allows you to fill in pre-prepared forms, is included in protective mixtures for concrete, wood, metal. Gives products a unique shine.

- "Artline Crystal Epoxy" (Artline Crystal Epoxy). The tool is ideal for creating crafts, jewelry, other types of needlework and creativity.

- Etal Optic (Etal Optic). Two-component tool for casting countertops, dioramas, models, small sculptural forms.

- Pebeo Crystal Resin Gedeo. This is a transparent resin for hobbies and creativity, has a low cost and is sold in convenient small packages.

- Linkuid 3D OPTI. Filling optical transparent material, on its basis are made key rings, jewelry, souvenirs, 3D floors, countertops.

- Crystal 9 and Crystal 7. Very viscous resins, used to create products with a lens or a high dome, have high hardness.

- Gold Glass by Poly Max. Special resin for jewelry, sold in small and large packages (up to 13.5 kg).

- "Vitakhim" KER 828. It is used in radio electronics, electrical engineering, on its basis make casting and impregnating compounds.

- LIQUID GLASS. Epoxy in a package of 150 ml for crafts, creativity, jewelry making.

- Vitreous varnish Cernit. It is a liquid resin complete with a hardener, it is recommended for the creation of protective coatings on wood, metal.

- "Epoxy resin L". This is a transparent resin for tuning, also suitable for finishing carbon fiber parts for cars and motorcycles.

- Epidian 601. Designed for casting floors, pipes, containers, creating composites.

- YD 128. It is used for the preparation of epoxy compounds, adhesives, sealants.

- Epoxacast 690. This absolutely transparent resin is intended for needlework and hobby, creativity.

- EpoxyMax Decor. Means for decorative works, perfectly combined with crumbs of marble, quartz, granite.

- Compound K-153. It is used for sealing electrical products, as well as parts regularly subjected to shock, vibration loads.

Application area

The material has taken a strong position in industry and everyday life, but now there are more and more new areas of its mass application. The most common areas of use of the tool are as follows:

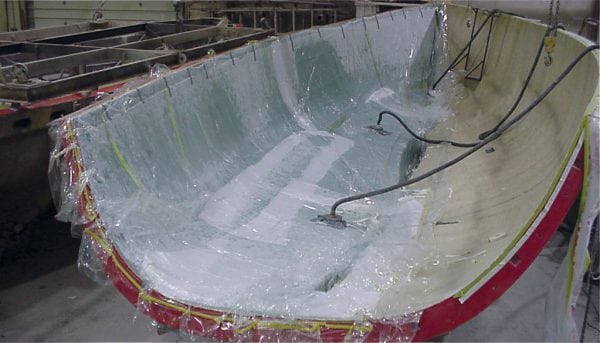

- impregnation of glass fiber, fiberglass;

- the creation of fiberglass, carbon fiber, other types of plastic;

- bonding parts in electrical engineering, radio electronics;

- waterproofing of pools;

- pouring floors and basements, the development of casting compounds and plastic cement;

- production of paints, varnishes, impregnations, putties;

- inclusion of chemically resistant coatings;

- boat sealing;

- application in aircraft industry, automobile industry, shipbuilding;

- creation of fasteners for earth-space missiles;

- sewing body armor;

- car body repair;

- production of jewelry, haberdashery, products for the kitchen, bathroom, home and everyday life;

- crafts;

- filling and sealing boards, computer chips.

It is difficult to list all areas and directions of epoxy exploitation. Where to get material for work? A variety of brands are sold in large markets (Castorama, IKEA), in all stores of building materials.

to contents ↑Combining epoxy with other materials

Epoxy resins can impregnate woven materials to enhance strength in harsh environments. Their use is limited only because of the high cost. Also epoxy is perfectly combined with other types of resins, including polyester. There is only one important condition - you must not allow contacting materials in liquid form. First, a layer of polyester is made, after it hardens, an epoxy is applied. The reverse combination gives a bad effect, it is not used.

to contents ↑Hardeners for epoxy

It is the combination of liquid resin and hardener that starts the polymerization process, allows you to cast a variety of products. How to determine which hardener is needed? Usually it comes with a tool, based on it - amines or phenols.

The ratio of hardener and resin may be different - from 1: 1 or more. Excess or lack of fluid will adversely affect the quality of the finished polymer. Its strength, resistance to heat, and the influence of chemicals will decrease. If there is little hardener, the mass may remain sticky.

to contents ↑Epoxy Quality Standards

When purchasing material, you need to check a number of important indicators - GOST compliance, shelf life (12 months).If the product is imported, it has customs codes that meet the requirements of the HS (Commodity Nomenclature for Foreign Economic Activity).

to contents ↑You should also clarify the storage conditions of the material, otherwise it could deteriorate (they are indicated in the instructions, it is usually recommended to store the product at temperatures up to +35 degrees). It is especially important to buy high-quality material if large volumes are required.

Safety precautions

After curing, the epoxy is considered completely harmless to the body. Nevertheless, care must be taken in the process, solvents are compounds toxic to humans. When inhaled, they cause damage to the respiratory system, and on skin contact - burns, dermatitis.

Work with epoxy should only be in gloves, work clothes, a respirator. When grinding products put on glasses. After contact with the resin, the skin is immediately washed with soap or rubbed with alcohol. All work is carried out only in a room with forced ventilation.