Mashing of joints is done after finishing the floor or walls with tiles. The quality of the joints depends on the selection of material, which will subsequently determine the attractiveness of the room, the service life of the coating.

- Scope and characteristics of the material

- Composition and properties

- Advantages and disadvantages

- Choice of color and manufacturer

- Instructions for working with the composition

- Materials and Tools

- Solution preparation

- Mashing seams

- Tile cleaning

- Possible mistakes

- Further operation of the coating

Epoxy grout for tiles in the construction market has appeared recently, but has already managed to gain the trust of professionals. Previously, it was used only in industrial premises, now grouting is used in houses and apartments.

to contents ↑Scope and characteristics of the material

Epoxy grout - white, black or colored material, a mixture intended for application on the seam between tiles, mosaics. It performs decorative and protective functions, is in great demand because of high quality, strength, unpretentiousness. Due to the variety of colors, the product is combined with any type of interior.

Unlike epoxy based tile adhesive, grout paste has a slightly different composition. This is a two-component product containing special fillers and additives, including those that increase the decorativeness of the material.

Epoxy grout is successfully used for finishing indoors and is used for outdoor applications. Suitable for all types of tiles, even for glossy, transparent, agglomerated, porcelain tiles. The restrictions apply only to grouting joints on fireplaces and stoves - epoxy is not suitable for them.

Main scopes:

- kitchen, bathroom, bathroom, shower, hallway;

- bathhouse, sauna, pool bowl;

- terraces, open areas;

- balconies, loggias;

- facing the house outside;

- surfaces equipped with a "warm floor" design;

- non-residential premises;

- garages and car washes;

- workshops and laboratories.

Epoxy grout is suitable for sealing tiles with seams, the width of which varies over a wide range - from 1 to 15 mm.

to contents ↑Composition and properties

Epoxy resin for joints is included in the grout without fail as a base. The material is two-component, because in addition to resin, it is necessary to use a hardener (organic catalyst). After mixing components A and B, the grout will take on a finished form, harden, and begin to have final properties.

The following substances are added to the resin:

- pigments

- silicon filler;

- quartz (silicate) sand;

- polymers;

- water repellents;

- antiseptic, fungicidal additives.

Epoxy grout sets an order of magnitude faster than cement grout. All stains and residues should be removed from the tile in a timely manner, otherwise it will be problematic to get rid of them in the future. In appearance, the finished mixture is a homogeneous, even mass without lumps, which has the following properties:

- Hydrophobic composition. The grout paste provides 100% waterproofing to the joint, therefore, even in the wettest rooms, the operation will be comfortable.

- Durability, reliability. The hardened composition becomes solid, does not crumble, does not deteriorate over time. It serves a very long time - up to 50 years.

- Resistance to chemicals.Grout does not suffer from contact with household chemicals, detergents, inert even to alkalis and moderately aggressive acids.

- Elasticity. Some substrates may undergo vibration and the epoxy will not allow the grout to crumble.

- Resistance to ultraviolet radiation. The material does not fade from the influence of the sun.

to contents ↑It’s easy to take care of the tiles: thanks to the grout, dust and dirt do not accumulate between the joints, they remain clean. Fungus and mold do not form, which is facilitated by special additives.

Advantages and disadvantages

The structure of the frozen mixture resembles plastic - it is smooth and looks very attractive. A huge advantage of the material is the ability to clean the floor in any convenient way:

- with funds;

- with brushes, including metal.

The tile is more likely to be damaged than the epoxy grout - it is so durable.

Other advantages of the material:

- a huge variety of colors and shades;

- an opportunity to apply for any rooms;

- maintaining the perfect look in all weather conditions during active use;

- lack of need for updating;

- the ability to replace tile glue, which is important for mosaics or panels;

- drying without cracks;

- lack of reaction to temperature changes;

- harmless to humans after drying.

The material also has disadvantages. It will be difficult for a beginner to glue on an epoxy and rub the seams. The product quickly freezes, it is not easy to adapt to it without experience. The repair price is not happy - the cost of epoxy grouting paste is much higher than the price of cement. For grouting, you will have to buy special devices, without which it is impossible to work with epoxy. Another disadvantage lies in the strength of the material. If you need to replace the tiles, you will have to try - removing it will be somewhat more difficult than with other types of grouts.

to contents ↑Choice of color and manufacturer

The selection of the shade of the grout paste is carried out after the acquisition of the tile. The content of pigments causes a very rich variety of shades of tiles, from which you must choose the right one. But to do this without skill is not so simple. Seams can give a completely different look to the tile, and how to decorate the coating, and make it faded, inexpressive. The right shade will help smooth out minor imperfections, emphasize advantages.

Specialists give such tips for buying a grout:

- Light pasta made in pastel colors helps visually combine the tiles into a single whole. The dark grout mass, on the contrary, divides the material into separate squares or rectangles, emphasizes the boundaries.

- If there is a large, bright pattern on the tile, you should take into account the size of the room. In a small room you need to apply a grout similar to the lightest color of the tile. In a large room, the grout mass is selected to the darkest shade that is present on the tile.

- For plain ceramics, grout is chosen for the shade of interior items, but from the same gamut as the coating itself.

- If there is a colorful bright mosaic, you should buy a white, beige or gray grout. The same colors are applied if it was not possible to find a suitable composition. Nevertheless, a white grout for the floor is not recommended - it will still be dirty and will soon seem dirty.

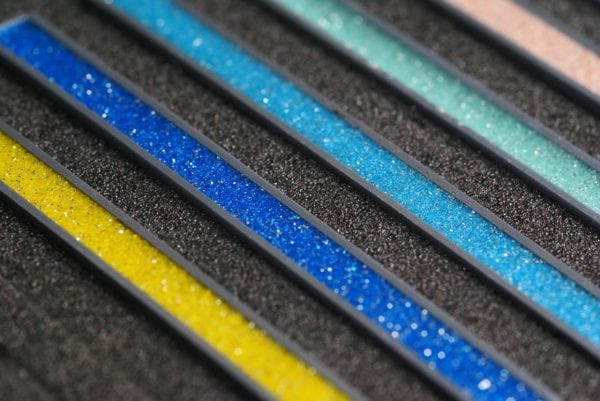

Now there are even absolutely transparent grouting materials on sale, they are usually bought for glass tiles, mosaics. There are also sophisticated products in stores - with sparkles, mother of pearl, metallic and even creating the illusion of stars. You can purchase a white grout and tint it with special dyes, which are also sold in construction stores.

What brand of epoxy grout to choose? The popular products of the Italian company Litokol are two-component epoxy mixtures that have high acid, alkali resistance. They can be used for interior and exterior decoration, go well with porcelain stoneware, tiles, mosaics, and natural stone.

The color scheme is diverse - includes more than 94 shades, including "gold", "platinum", "silver" and many others.All Litokol brand epoxy grouts are resistant to temperatures from -20 to +100 degrees.

The main varieties of grouts Litokol:

- Starlike C350 Crystal - a colorless mass for glass, artistic tiles and mosaics, suitable for illuminated surfaces;

- Starlike Defender - ideal for any tile, can close even the widest seams;

- Starlike Color Crystal - suitable for glass mosaics, suitable for seams up to 2 mm wide;

- Litochrom Starlike - has the widest range of colors, including fluorescent and metallic shades;

- Epoxystuk X90 - used outdoors due to its special strength.

Among other brands, builders distinguish Mapei epoxy grouts. The Mapei Kerapoxy product has the smallest grain size, but is available in only 26 colors, the most popular.

Russian grout Diamond is used exclusively for the bathroom, includes 46 colors.

Means Osnovit can be used at extreme temperatures - in the range of -50 ... + 75 degrees, it is highly resistant to fungus. The price per kilogram of grouts varies from 800 to 3000 rubles.

to contents ↑Instructions for working with the composition

Before using the material, you must carefully read the instructions. It is recommended to practice on an inconspicuous area, after diluting a small portion of the product.

You can still work with ordinary cement grout first - this will also allow you to acquire certain skills. Prepare the epoxy mixture in small portions, work as quickly as possible, otherwise the composition will seize in the container and deteriorate.

to contents ↑Materials and Tools

To work with epoxy, you should definitely buy such devices, consumables and tools:

- rubber spatula with a durable handle;

- cellulose sponge (can be replaced with a foam sponge, but the latter will soon fail);

- skipper (bucket with rollers for pressing);

- grater with a cellulose nozzle to remove drips;

- latex gloves;

- tile and glass cleaner.

To mix the grout, it is better to have a drill with a special nozzle-mixer. Manually thoroughly mixing the mixture is much more difficult. To wipe the tiles, you should buy a cellulose sponge - it can easily process up to 30 square meters. m of seams without losing appearance and properties.

to contents ↑Solution preparation

Two-component material necessarily requires preparation before application. Components A and B should be mixed strictly in the proportions indicated on the label. For different brands, the ratio may vary.

It is necessary to measure no more than 300 g of the mixture, calculate the proportions and knead. Weighing should be done on a kitchen scale - they are very accurate. Kohler, if necessary, is introduced into the finished mass. It must be remembered that its viability is no more than 30-60 minutes, so it is better to start work immediately.

to contents ↑Mashing seams

The tile, before applying the mass, should be dry, clean, glue residues removed from the cracks. Crosses, the alignment system is also removed. In order to reduce the complexity, you can paste the edges of the tiles with paper tape. A rubber trowel is required for mashing.

Operating procedure:

- apply a mass with a spatula, carefully distribute it at the seams of the tile section;

- to form joints, completely filling the seams;

- take a sponge, dip in clean water, carefully wash the seams (do not reach the end of the seams, so as not to wet the non-wiped area);

- after the formation of the seam, rinse the sponge again, wipe it with a finishing one (grout will remain semi-liquid);

- after half an hour, when the joint dries, you can sprinkle it with water from the spray gun and iron it again.

In the process, large excess grout is removed immediately with a clean sponge or grater with a fiber-optic nozzle. After 5 to 10 minutes, removing them will be much more difficult.

to contents ↑Tile cleaning

Finish work without the appearance of plaque on the tile is almost impossible. You will have to clean it with special detergents (for example, Litonet from stains).

to contents ↑In order not to damage the formed seams, cleaning is done only after a day, not earlier. A microfiber cloth or soft sponge is required. It is necessary to wash out a raid several times, periodically changing water. Then wipe the tile dry.Finally, contaminants are washed off only during operation.

Possible mistakes

The most common mistake for beginners is to grout without accurately measuring the proportions. It is impossible to prepare material by eye, the instructions should be strictly observed. Otherwise, the mass will be damaged.

Another possible mistake is to leave the grout on the tile in the hope of removing it after the work is completed. It will be necessary to clean the composition mechanically, because the material does not dissolve in water, the risk of damage to the tile is high.

Do not work with epoxy using conventional tools that were previously used for cement grouts. A special spatula and other tools should be purchased, otherwise the application technique will become much more complicated.

to contents ↑Further operation of the coating

Despite the fact that the curing time of the grout mixture is several hours, you can use the floor in the bathroom or other room after 4 - 5 days. This will eliminate scratching, damage to the fresh mixture, because it is almost impossible to fix blemishes and remove traces from it. But then no damage will be scary to the seams - they can be washed, cleaned and enjoy the beauty and ease of care.