Gelcoat is used to protect various products, creating a high-quality and beautiful coating. There are different types of gelcoat, and in properties they are very different from ordinary paints. The technology of using materials is also different, it is worth considering all issues in more detail.

- Material Features

- Main characteristics

- Gelcoat Application - Safety

- How to use the material - rules

- Types of gelcoat

- Matrix gelcoat

- Matrix resins

Material Features

Gelcoat (gelcoat, gelcoat) - a special material in the form of a gel used to form a protective and decorative coating of composites. Most often, an epoxy polymer is included, but there are other types of gelcoats based on polyester resin. Also, the composition may include other components - pigments of a certain color, binders, fillers.

Gelcoat is an epoxy or polyester resin for matrices. First, it is applied to the matrix, and after curing, one or several reinforcing layers are performed. Once again impregnated with an epoxy coating. After removing the product from the mold, its front side will be covered with gelcoat.

There is a huge variety of colors, the most popular are green, red, brown, gray shades. This material should not be confused with simple paint - applying the gel in the usual way will not work, it is designed for professional painting using matrices. But there are special types of products in aerosols and sprays that are suitable even for beginners. The main difference between gelcoat and paint is that it becomes part of a single whole, and is not just a coating that can be separated if necessary.

to contents ↑Main characteristics

A high-quality gelcoat always has the necessary manufacturing certificates, a safety data sheet. The material serves as a protective and finishing layer and helps to save the hulls of boats, boats and many other products from osmosis and early wear. Here are the basic properties of the coating:

- not sensitive to ultraviolet radiation;

- provides a beautiful shine, works like a polish, gives the proper presentation;

- gives resistance to mechanical stress, the influence of an aggressive environment, temperature extremes;

- It has a low level of emission of harmful elements into the atmosphere after drying.

In shipbuilding, it is preferable to use gels based on polyesters - they better adhere to the surface of ships, form the most durable bonds. The layer of these materials is thicker than that of paints (0.5-0.8 mm or more). Its durability is amazing, and often you will not have to change the coating even with the most intensive use of the product. Ultraviolet white gelcoat reflects best of all, and dark shades absorb it, heating up and more likely collapsing. That is why white hulls of boats and yachts are more common.

to contents ↑Gelcoat Application - Safety

The dried material is harmless to the body, especially since many coatings are used outdoors. But at the stage of application to the environment, harmful substances are released. Basically, we are talking about styrene. It is dangerous for allergy sufferers, irritates the respiratory system, the mucous membrane of the eyes, and provokes the appearance of signs of dermatitis on the skin. Therefore, work is possible only with the use of personal protective equipment - respirators, gloves, glasses, durable clothing.It is important to provide forced ventilation in the room so as not to breathe in gelcoat vapors.

This material has high flammability and can cause a fire. Work with him near any sources of fire is strictly prohibited. If a fire occurs, use suitable extinguishing methods - dry sand or chemicals, water fog, spray foam from a fire extinguisher.

to contents ↑How to use the material - rules

To apply the product with your own hands, you can use spray guns, spray guns, and brushes. The ambient temperature should not be below +18 degrees, otherwise the material will dry for a long time, curing will occur with violations. As a result, the service life of the coating will decrease. The upper acceptable threshold is +25 degrees.

Before starting gelcoat mix well. Since it is sold in large containers, it is advisable to cast a portion into a small container. There, the material should be diluted with a catalyst according to the proportion specified in the instructions (usually 2%). Then the solution is mixed again.

Brush application is usually used to paint small areas, more significant work is carried out mechanically. The coating is done in two layers, each of which must be applied with maximum accuracy. This is necessary to prevent the appearance of air bubbles - they reduce the surface quality. How much does each coat dry? 4 minutes is enough, and you can spray a new layer of the product. The final coating should have a thickness of 0.5 mm, optimally 0.8 mm.

to contents ↑

Types of gelcoat

The gelcoat classification is based on their constituent resins. Materials of the premium class are made on the basis of epoxy resin; they cost an order of magnitude more expensive. Gels obtained by the synthesis of polyester resins are cheaper. Less popular are compounds based on other resins:

- orthophthalic;

- isophthalic;

- neopentyl glycol;

- vinyl ester.

A separate line is the matrix and slow-burning (self-extinguishing) gelcoats. The former are used for the manufacture of matrices, or ingots. In the latter, special flame retardants are added that do not allow the coating to burn.

According to the method of applying to the surface, the materials are as follows:

- internal - cover the inside of the product to smooth out defects, there is no gloss in them;

- external - applied to the external side of the subject, so they should have higher decorative qualities;

- topcoats - are intended for the inner fiberglass surface in order to impart special decorative properties (include wax in the composition).

Also, all gels are divided into structural, elastic, high-temperature. They are colored and white, as well as colorless. If the material does not have a shade, it can be painted in any color by adding special pigments.

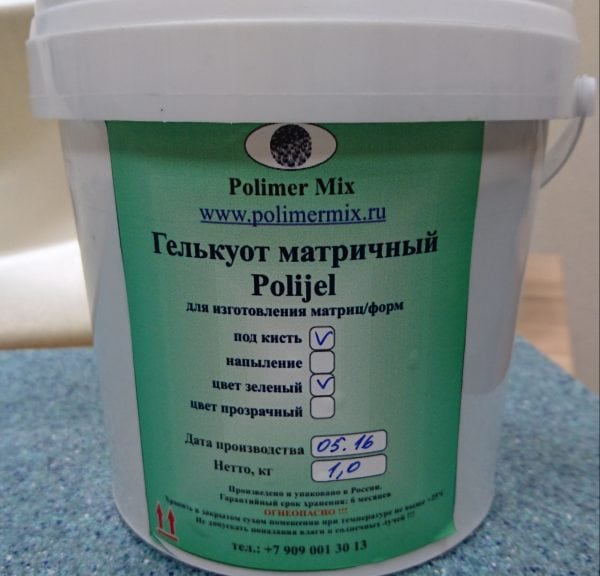

to contents ↑Matrix gelcoat

Matrix types of gel are gel-like products consisting of a resin, a dye, as well as a number of additives. Such gelcoat always has an extended service life, allows you to create molds for pouring and protect products from harmful environmental influences. Gelcoat prescriptions include masking the structure of fiberglass and imparting decorative properties.

Matrix gelcoat can be external and internal, from the last make the first coating layer. Then, fiberglass and resin are applied to the base. After removing the product from the matrix, an external decorative layer can be applied to it. Before the manufacture of the matrix make models of plywood, polystyrene. It is important that the base of the layout is smooth, then the finished coating will turn out to be of high quality. The product should be easily removed from the mold without damage, for which its interior is covered with wax. If the shape is unusual, the layout is prepared from several parts (detachable matrix with partitions).

A thicker matrix gelcoat is applied in a thicker layer than conventional material - from 1 mm. In some cases, instead of fiberglass, a glass veil is used, it allows you to create elegant contours and bends of the finished coating, if necessary according to the layout. Also, glass mats are suitable for the operation of the matrix gelcoat, fiberglass for larger, coarse products.

to contents ↑Matrix resins

Most of the produced grades of resins have high strength characteristics and are characterized by excellent physicochemical properties. How to replace such materials? There are no analogues, only such resins reliably protect the base from damage by ultraviolet, do not shrink, and are heat-resistant.

Here are the most popular brands of matrix resins:

- G 300 TPB - thixotropic resin based on orthophthalic, is characterized by high heat resistance, resistance to hydrolysis. It is used to create hulls of cars and ships, wind generators.

- S 599 TE - polyester resin, used for the manufacture of thermoplastics, withstands the highest temperatures.

- AROPOL One Shot - allows you to create high-quality molds for pouring gelcoats, characterized by a complete lack of shrinkage.

How exactly do matrices? For this, various matrix gelcoats are used, for example, MAXGUARD GT - based on vinyl ester resin. The material is applied with a brush or spray in two layers. When the last layer hardens, we carry out the Skin coat layer - it includes glass mat and another powder-bound mat. Polyester resin acts as a binder. At the third stage, the matrix is laminated using the same polyester resin. General drying is carried out within 24 hours, after which it is ready for use.