If the concrete wall has lost its strength, it can be strengthened without disassembly. This will help stop the destruction, which inevitably occurs over time, will contribute to sealing, will not allow moisture to penetrate. There is an effective technology - concrete injection. It will restore the bearing capacity of the wall and increase its waterproofing properties.

- Technology features

- Types of structures

- Foundations and basements

- Cracks and seams in concrete

- Brickwork and walls

- Injection Solutions

- Epoxy resin

- Polyurethane resin

- Silicate resin

- Cement-sand composition

- Acrylate gel

- Injection steps

- Training

- Injection

- Filling Schemes

- Waterproofing

- The final stage

Technology features

Injection is a modern method of restoring the strength of concrete, stone structures, strengthening brickwork, as well as a method of waterproofing joints. The injection technique is based on the penetration of a special solution into all voids - in cracks, cracks, pores and holes. The composition is introduced under strong pressure by using special devices.

The hydrophobic material is pumped into the insulated object or placed between the surface and the outer layer. This helps create a waterproof membrane between the environment and the structure. Also, the insulating layer will serve as a protective frame, reliably strengthening the building.

The advantages of injecting over major overhauls with complete dismantling are obvious:

- the ability to reduce construction restoration costs;

- the ability of solutions to close even large cracks, sections of structural delamination;

- creation of a monolithic layer without seams, joints;

- Strengthening the strength of the walls, foundation;

- elimination of emergency leaks;

- safety for humans in contact with solutions of drinking water.

Of the minuses, it is necessary to indicate the high cost of equipment for injection, but it can be rented. It is impossible to carry out work without proper experience, this can provoke even greater destruction of buildings. Only professionals should entrust the process.

to contents ↑If the reinforcement does not have rust, the damage is moderate, then the method of injecting the base is carried out in a standard way. When the damage is more serious, remove the destroyed areas and seal them with special mixtures.

Types of structures

Injection waterproofing is a universal method with a wide scope. Most often, it is used on old objects made of brick, concrete, stone. Here are the main purposes of the technology:

- filling cracks, voids, capillaries inside buildings and structures (including defects formed during violations of the construction technique);

- insulation of cold joints on concrete, reinforced concrete structures;

- repair of deformation joints;

- installation of internal waterproofing in order to remove capillary suction;

- isolation of grounded objects.

Injection is used for complex structures - pools, parking lots, sewers, metro, but no less often used for residential buildings and their individual parts.

to contents ↑Foundations and basements

Repair of the foundation is carried out using cement, cement-sand mortar.Also, compounds based on siloxanes and silicates are suitable for this purpose. Thanks to this technique, the insulation properties of the foundation are enhanced, it will be protected from the negative effects of external factors. This mainly relates to destruction from temperature extremes and groundwater.

The selected composition is pumped under pressure into the damaged areas of the foundation so that it penetrates even the smallest pores, cracks. Further, the finished object is carefully checked by engineers: water flows should no longer have a destructive effect on the material.

In the same way, cellars are injected. The work allows vertical isolation and horizontal soil cutoff to protect the structure from the penetration of capillary moisture. Thus, you can restore the room without digging and parsing old masonry.

to contents ↑Cracks and seams in concrete

Concrete injection is used more often than the repair of other building materials. The technique helps to waterproof the cold and moving joints, to prevent the growth of cracks. After termination, water will no longer penetrate through defects. With satisfactory quality of concrete, such manipulations are sufficient for its serious strengthening. But with a poor condition of the material, severe corrosion of the reinforcement, part of the structure has to be removed, after which it is restored with cement or epoxy resin.

to contents ↑For optimal repair of cracks, joints in concrete, it is important to choose the right composition for injection. Microcement is best suited, which has the desired viscosity, it has almost no shrinkage, and you can work with the material at any ambient temperature.

Brickwork and walls

Injecting structures and individual brick structures several times increases the quality of construction, creates complete water resistance, but does not change the normal vapor permeability. Also, the technique greatly increases the reliability of the brick, making it resistant to the influence of damaging factors. The injection method of repair does not require large expenses, which inevitably arise when disassembling old masonry and erecting a new one.

For bricks, work is most often carried out using microcement. It helps to create an airtight curtain. This is achieved by pumping solutions from the inside of the building. There is also a method of strengthening the structure from the outside, it is less costly.

to contents ↑Injection Solutions

The choice of composition is based on the requirements for its properties. Here are the most important of them:

- moderate or low viscosity;

- excellent penetration;

- high degree of adhesion to the surface;

- resistance to corrosion;

- lack of significant shrinkage;

- long service life.

All the listed qualities are in compositions based on epoxy, cement, polyurethane resin, as well as the latest waterproofing materials.

to contents ↑Epoxy resin

Material of this type has only one drawback - it is not cheap. Epoxy has high strength and adhesion, chemical resistance, gives a strong seam, dries quickly. The resin is able to completely repair the damaged surface even with a significant degree of destruction. It can also glue together parts of structures into a single whole, close cracks (large and small), strengthen joints, fill cavities and indentations. After injecting concrete and other materials with epoxy, the load-bearing capacity of structures increases several times.

to contents ↑Polyurethane resin

These types of resins are used if the defects are small (up to 1 mm). A feature of liquid polyurethane is the rapid penetration into small pores, which helps to reconstruct concrete, stone, brick. The resin also creates additional insulation, even wet seams can be treated with the material, and it can be used to stop the flow of water.

to contents ↑Polyurethane resins contain hydroactive polyurethane. After contact with moisture, it sharply increases the volume, forming a spongy structure.The foaming time of the product is low, so it is often used to eliminate accidental leaks.

Silicate resin

This type of resin hardens even faster than polyurethane, has minimal shrinkage. They have high mechanical strength, are harmless to humans and the environment. Silicate resins are widely used to stabilize soils, adjacent rocks, fill cavities and defects, and organize a waterproofing layer. The material can be mixed with microcement.

Cement-sand composition

With these solutions you can fill any cracks and pits in concrete, masonry, as well as equip insulation from moisture. It is only important to choose a fraction of cement that will coincide with the masonry in strength. Typically, cement is used for significant damage, because it is reliable and the cheapest. There are special microcements and polycements for injection, they are characterized by a special degree of grinding. Such compounds quickly penetrate even into small pores and defects.

to contents ↑Acrylate gel

Acrylic or acrylate gel has a low viscosity and the ability to increase in size after contact with water. It creates a powerful waterproof barrier, fills cracks, dries the space around it. Most often, gels are used for such purposes:

- rehabilitation of the deformation center;

- cutting off capillary moisture;

- sealing of any structures with the membrane method;

- injection of brick buildings, stone structures.

Injection steps

For work, you should purchase or rent special equipment. When hiring specialists, they will come with existing devices. The following devices are used:

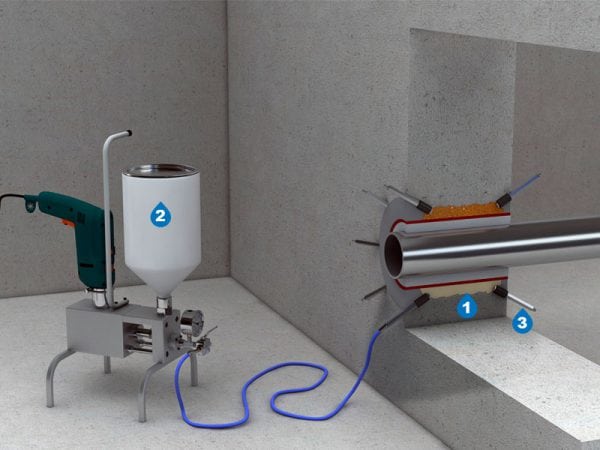

- Injection pump. The cost of sediment for cement is high - up to 100 thousand rubles, 2-3 times less than the price of devices for injecting epoxy or other types of resins. The cheapest are hand pumps.

- Packers for injection. These are pipes that feed the composition into concrete or other base material. Their price is low, the products are consumables.

The injectable composition itself is also purchased for work, the price per kilogram is 400-1000 rubles. Additionally, a protective tape (from 250 rubles per roll) will be needed.

to contents ↑Training

The preparatory phase includes a thorough inspection and identification of surface problems. All stratification zones should be removed and rust removed from the iron structures. The easiest way to do this is with a grinder. In the presence of rust, the quality of work will decrease, the compositions will grapple with the base worse.

Injection

First, a specialist will drill several holes along the crack. They are staggered. Then packers are inserted into them, pump hoses are connected to the latter. Manually or automatically, the solution is fed into the holes. It is important to enter a precisely measured quantity, otherwise the cracks can move apart more.

to contents ↑Filling Schemes

It is possible to carry out work on the injection of concrete or other materials according to the following schemes:

- horizontal - from two sides, from the center to the edges;

- vertical - from bottom to top;

- ceiling - from anywhere in the center.

Waterproofing

Since many structures are operated in conditions of high humidity, it is required to ensure their moisture insulation. A special technology is used for this. First, polyurethane resin is poured through the packers, which creates a porous structure. Next, these pores are sealed with epoxy. So you can provide high-quality waterproofing.

to contents ↑

The final stage

At the end of the work, the packers are removed, the surfaces are covered with a durable film for the duration of the complete polymerization of the compositions - up to 2 weeks. Then you can proceed to the decorative finish, if necessary.The room will be reliably protected and strengthened, the process of its destruction with timely repair work will stop.