Epoxy resin is used everywhere - in construction, repair, for the manufacture of adhesives, self-leveling floors, in various industries. In recent years, the manufacture of jewelry based on epoxy - bracelets, beads, brooches - has become increasingly popular.

In general, this wonderful material is suitable for embodying the most daring ideas, in addition, it can be painted in a variety of colors. Dye for epoxy is purchased in the store or made by yourself on the basis of improvised means.

to contents ↑Need for resin staining

Kohler for epoxy, or pigment concentrate - a special tool for dyeing resins, changing its primary color. Tinting is done for the so-called jewelry resins - epoxies designed for creativity.

Typically, such materials have an absolute, crystalline transparency, which allows staining in the most original colors. Also, the product can give shine, make color transitions, overflows.

to contents ↑Specialized paints

In order not to worry about the result of painting, it is better to use products specially designed for this. They are sold in needlework stores, for artists, most often they are acrylic. Epoxy paint can be of this type:

- one-color - on sale there are almost all known colors of paints (blue, yellow, gray and many others, even black and white);

- fluorescent (with a phosphor) - can glow in the dark thanks to special components, it is colored and colorless;

- shade matte - gives the epoxy a noble dullness, which allows you to create stylish jewelry and other products;

- mother-of-pearl or metallic - the finished thing will beautifully shimmer;

- with sparkles - designed to give a sparkling, festive look to products.

Depending on the amount of paint you can provide a completely different type of finished thing. So, if you tint the resin with a drop of dye, the shade of the epoxy will be translucent. A darker color can be made by introducing more pigment. To make the color saturated, deep, transparent resin must first be painted white, then to the desired master.

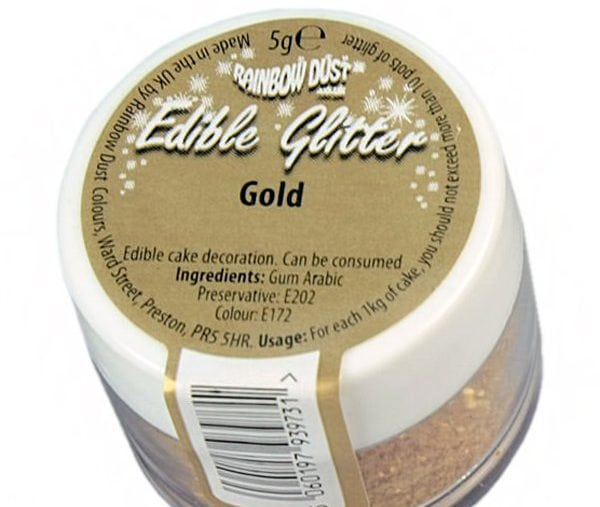

How to tint the material, which paint to choose? The ideal option is to buy a product from the same manufacturer that released the epoxy itself. For example, excellent tinting pastes, powders are produced by Poly Max Dream, MG-Epox-Color. Colors are usually produced in small packages (5-10 g each), their price is 50-200 rubles. An example of paint can be called “Glitter” with sparkles, here are the main colors:

- red;

- green

- black

- white

- brown;

- blue

- golden;

- purple

- orange

The color consumption is small, they are very economical. To obtain a transparent resin add no more than 0.01-0.05% of the paint (percentage of the total mass of epoxy). For painting in an opaque color, 5% of the tint is introduced into the mixture, this amount is the maximum allowable. Different colors can be mixed to get unique shades.

to contents ↑Available tinting

Epoxy can be painted in another way. Pigment substances are not always at hand, sometimes the desired color is not in the store. Home remedies will come to the rescue. It is important that they do not contain water.

You can paint an epoxy with such means:

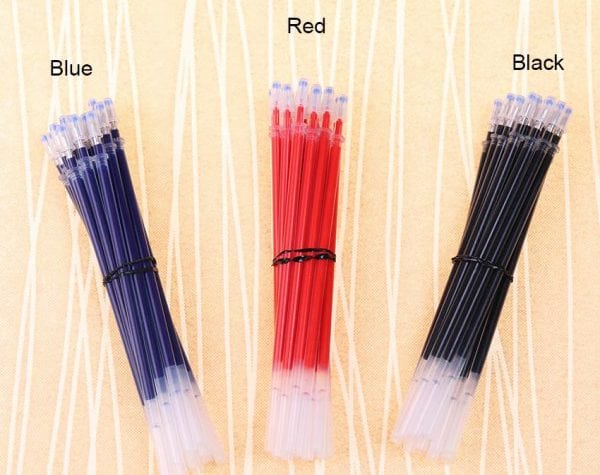

- gel pen ink in any color - you just need to squeeze a little ink into the resin, the shade will be bright, saturated;

- ink simple pens;

- conventional oil or stained glass paints for drawing, as well as nitro-paint, alkyd paint, stain (it is important to introduce a hardener after such means);

- ink for painting polymer clay;

- ink for the printer, activated carbon (give a deep black color);

- talcum powder, powder, crushed chalk, kaolin, tooth powder (will provide white color);

- pharmacy green.

Coloring Tips and the Right Technique

In order for the painting to succeed, you must strictly follow the manufacturer's recommendations on the use of colorings. But what method to use if home-made tools are added instead of purchased components? Here are the rules for using dyes:

- the amount of oil, alkyd paints, nitro paints is less than 10%, otherwise the epoxy after solidification will resemble rubber;

- other substances are added in a volume of not more than 5–7%;

- some expensive resins do not respond to water penetration, but, for the most part, the epoxy does not tolerate even accidental moisture and immediately deteriorates;

- it is necessary to work at a temperature of about 22-23 degrees, in this case, the coloring and curing of the material will take place without problems.

Safety precautions should be followed during tinting. Gloves are put on hands, respiratory tract must be protected with a respirator. If tar gets on the skin, it is washed with soap.

Some resins contain solvents; work with them only in a well-ventilated area. For mixing substances, disposable tableware is used to immediately throw it away.

To work, you need to prepare:

- a small disposable spoon;

- a glass;

- several syringes;

- dyes;

- basis for filling (form).

First, a hardener is added to the epoxy. It is sold separately or complete with epoxy, but the instructions always indicate the exact proportions of the components. Mixing is recommended in small portions, large volumes are very hot, the resin may deteriorate. Next, the product is poured into glasses, depending on how many shades you need to get.

Pigment, pearlescent or luminous paint is introduced into the finished epoxy as soon as possible. Stir the material thoroughly with a spoon for 5-7 minutes, until the mass becomes completely homogeneous. Leave the mixture for 15 minutes at room temperature to exit the liquid bubbles, then pour into the mold. It must be maintained for the necessary time for complete curing, usually a day.

To achieve transparency, it is better to breed epoxy with paint in a glass jar. Then you can immediately see how much pigment should be added, and the result will be perfect.

I tried using different improvised means to paint the epoxy. The resin is painted well. And I will add a hardener - the color disappears.

Use a THETA hardener, it is transparent, like resin. Color will not affect