Very beautiful and original jewelry is made from epoxy - especially when the technology is strictly followed. But even with the most experienced craftsman, the finished product can be a little uneven, there are often leaks on it. Epoxy polishing will help to cope with the problem. This stage will allow you to process jewelry and other manufactured items quickly and with excellent results.

Polishing Epoxy Products

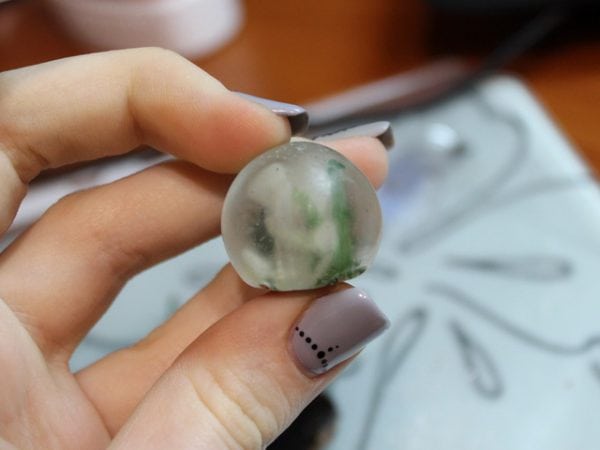

Many needlewomen now make jewelry from epoxy compound. “Home jewelers” know for sure that when a product is removed from the mold (mold), a groove is often formed on the pouring side. It turns out that epoxy as it solidifies slightly decreases in size and changes shape. No less often there is a need for the correction of smooth crystals, pendants, medallions. On their reverse side, stains, sagging, growths may appear. Also, the need for surface treatment is in the presence of such defects:

- excess casting mass;

- scratches and small chips;

- protruding edges;

- uneven, pointed edges;

- hollows.

to contents ↑If the defect is serious, you do not need to despair. You will have to carefully polish the item, and then apply another layer of epoxy. This will hide the flaw without loss of quality. All the cons will be smoothed out, the product will look perfect. Grinding and polishing is the final stage of work, giving completeness to the decoration.

Tools and materials

There are many ways to process finished jewelry at home. This is done manually or by mechanized method. The simplest work tools are a regular nail file, a trowel, sandpaper with fine grain. The manual method is used for grinding the most delicate products, for fine finishes. Larger objects are first polished with an emery cloth with a coarser abrasive, then the edges are cleaned clean, bringing them to the desired smoothness, transparency.

Also, to work with haberdashery, you may need these tools:

- Dremel - a hand tool with a rotating shaft, different nozzles, they can be polished jewelry;

- milling cutter (manicure machine) - works like a dremel, but has a lower number of revolutions.

If pendants, earrings, bracelets are made regularly, it is better to immediately purchase a dremel. It is convenient for them to drill holes for attaching rings, fastening wires. The only drawback is the unsuitability of a powerful device for the most delicate work, for micro-size crafts. Small parts are knocked out of the hands, in addition, there is a risk of injury. Therefore, you should have both a power tool and hand polishers.

to contents ↑Sanding Recommendations

In order not to have to remove too large defects, it is necessary to take preventive measures in advance, work carefully, carefully. Molds are poured slowly, without sudden movements, evenly.This will reduce the risk of grooves. The work table must be set exactly horizontally, then the epoxy will be distributed without sagging, warping.

To achieve a shiny surface, choose molds with glossy walls. The matte base of the molds will give the same “appearance” to epoxy jewelry.

The following is the procedure for polishing work, if defects on the products still formed:

- After shaking the jewelry out of the form, you need to carefully examine it. If there are major defects, rough processing is required first. It is ideal for her to use a polishing machine at speeds up to 1000 rpm. This method will eliminate waves, growths, make the product smoother.

- The second stage gives the decoration transparency. To do this, the item must be polished with a smaller abrasive. Apply professional circles with small grains, as well as special automotive polishing pastes. The circle is greased with paste, first make sure that it is dry, clean, without scratches.

- After using polishes, you can get a transparent, even surface of the hardened resin. Even the smallest flaws will be eliminated.

- At the end of the work, it is recommended to cover the product with a special varnish that protects pigments from UV radiation. It is also required to prevent yellowing.

Some authors advise polishing objects from epoxy with foam rubber circles, mounted on a drill, including small turns. Initially, they are walked along the edges with a fine-grained sandpaper with water, removing large irregularities. Next, foam and polishing paste bring the decoration to shine. If there is no polish, use soapy water. Felt nozzles cannot be used, they can ruin an epoxy item.

How to polish jewelry and other products if there are no special tools? You can take a regular manicure set. Roughnesses are cut off by them, then the surface is polished to the end with a sandpaper manually with water (using grain 600-800). At the end of the work they take a polish, rub it into the subject with the help of a cotton circle. The base becomes completely transparent. After using water-based parquet lacquer, which will give the decoration a complete look. Instead of this material, it is permissible to apply the coating with gel polish, then dry it with a special lamp for nails.

to contents ↑

Safety precautions

The material undergoes full polymerization after 24 hours; some resins can be used only after 48 hours. Sanding can only begin after curing the epoxy, otherwise the product will be damaged. Until the polymerization is complete, the resin is harmful to health, it releases toxic substances. It is equally harmful to inhale dust particles during grinding. Therefore, the mouth and nose should be protected with a respirator, eyes with glasses, hands with gloves. At the end of the work, the room must be thoroughly ventilated and the clothes washed.

Are all epoxies equally well polished? There was experience when the already frozen one remains minimally viscous (between plexiglass and PVC in elasticity). Or the matter is in non-compliance with the proportions (tried to comply). Now they offer resin for 3D floors and Art-array and Etal and others. What do you recommend?