Epoxy resin is one of the best materials for the manufacture of floors, beautiful glossy coatings, countertops. Epoxy hardens after mixing with the hardener, after which it acquires unique properties - resistance to water, strength. Special transparent epoxy resin for pouring is best treated. It allows you to create colorless, crystal clear products - 3D floors, advertising souvenirs and much more.

- Transparent Epoxy - Description

- Features of resin and brand

- The scope of the tool

- Transparent Resin Basics

Transparent Epoxy - Description

Epoxy - an oligomer containing epoxy groups that form crosslinked polymers under the influence of hardeners. Most resins are sold as two-component products - in one package the resin itself (thick, viscous, viscous mass) is in the other, and a hardener (liquid based on carboxylic acids or amines) is in the other. Most often, epoxy resins are made by polycondensation of epichlorohydrin with bisphenol A, they are called epoxy dianes.

Transparent resin from "relatives" is distinguished by optical transparency. She does not hold color, looks like glass. Both components of the mass are completely colorless, which makes it possible to use the mass for casting, to create a coating of walls or self-leveling floors. The highest quality products do not have yellowness, turbidity even after several years of operation. Epoxy for casting has another name - casting compound.

to contents ↑Features of resin and brand

Epoxy for decorative work is characterized by rapid solidification, which is based on the reaction of chemical polymerization (curing). That is why it is recommended to fill it with the floor, forms for various products already after the pictures, images were placed there. After casting, we get an original collage, and the picture will be completely “frozen”.

Transparent epoxy is suitable for volumetric fills - for this purpose, figures, shells, stones, other objects are placed inside the form. This will create a 3D effect.

Any resin for casting is modified - it contains special components that can modify the mass, giving it the desired properties. Also in production are used plasticizing additives that improve the elasticity of the epoxy, they do not allow it to crumble. A carefully selected composition guarantees the non-shrinking service of the finished coating - over time, it will not lose its original shape. Liquid resin has good fluidity to help get rid of bubbles.

What other properties does a product created by filling technology have? Here are the main ones:

- highest strength;

- harmlessness to humans;

- resistance to UV radiation, water, household chemicals;

- lack of crystallization even at low temperatures;

- high wear resistance;

- antistatic qualities;

- heat resistance.

The surface, flooded with resin, looks like liquid glass or ice, a transparent crystal. The specific effect depends on the type and brand of epoxy, because this material is produced by different manufacturers. Which brand is better? The most popular are such means:

- 3DOpti. It is presented in different containers - from 100 ml bottles to 10-20 kg buckets. Hardener included. It is widely used to create various interior items, works of authorship, can serve as a sealant.

- Der 330. Used for the manufacture of bulk floors, mortars, can serve as glue.

- Magic Crystal-3D. It helps to make beautiful 3D-coatings with a gloss effect, suitable for making jewelry. It can imitate ice, stone.

- Epoxy CR 100. It is also used for pouring polymer floors, capable of closing small cracks. Often this material is used to create an intermediate layer during the construction of buildings and other objects.

- Compound K-153. It is used for repair and sealing of electrical products, other items that are subject to vibration and shock loads.

- Epoxy compound 76 Crystal. Allows to produce 3D polymer floors, serves as a binder for colored sand, coatings such as "sand carpet".

- GoldGlass. The ideal solution for creativity, sold in syringes, bottles, banks of various sizes. The resin can be dyed with special pigments of any color.

Which resin to choose should be decided depending on its affiliation. Almost any transparent epoxy can be applied to plastic, metal, glass, wood, ceramics.

to contents ↑The scope of the tool

Compositions based on transparent epoxy are used for the manufacture of jewelry, trinkets, pendants, jewelry, various figurines and decorative elements. What else can be produced with this resin? The list of applications also includes promotional items, souvenirs, countertops, bathroom products, plumbing fixtures.

One of the main areas of use of epoxy is bulk floors with unique patterns. Also, the tool is suitable for creating glazed surfaces, mosaics, volume decoupage. In general, the use of a transparent compound can be broader and limited only by the user's imagination. The material is perfectly combined with wood, stone, beads, sand, dried flowers, insects, coffee beans.

Phosphors (components that glow in the dark), sparkles can be added to the polymer resin. Illumination is often mounted inside the countertops, and the LEDs create a soft, pleasant glow. Special dyes having a small particle size (5-200 μm) are sold for epoxy. They are evenly distributed inside the layer, creating a uniform shade without unpainted zones.

Other areas of epoxy use:

- waterproofing for various industries, sealing and sealing of electrical devices;

- coating the walls and bottom of boats, car parts;

- impregnation of fiberglass, fiberglass, fiberglass and yarn;

- reinforcing plaster, strengthening the thermal insulation of rooms;

- priming of walls, floors, porous surfaces;

- protection of products that are exposed to aggressive chemicals and water.

Transparent Resin Basics

Many masters successfully work with epoxy at home, using adhesives based on it, repairing various objects and products. But the instructions for using transparent material are much more complicated. From the first time it’s difficult to create a perfectly smooth, even surface with your own hands, you will have to train. A thorough study of the information will help ensure excellent fill quality without bubbles and other defects (oil stains, chips, tubercles).

It is strongly not recommended to start training on injection technology in large areas. This will require special preparation of the base, a perfectly mixed compound, even, layer-by-layer application.

Masters in bulk floors use the technique of rolling each layer until the moment when polymerization begins.The worker walks on spikes that do not allow the floor to be damaged, rolling is also not easy - he needs a gear roller for polymer coatings. It looks like a massage comb. After applying the roller, all air bubbles are removed from the mass. It is easy to guess that it is problematic to carry out such work yourself.

For the manufacture of jewelry, pouring small items (badges, labels, souvenirs, natural material) requires much less effort. It is necessary to prepare such tools and materials:

- a form with or without a separator;

- epoxy resin and hardener;

- dyes;

- a wooden stick;

- disposable tableware.

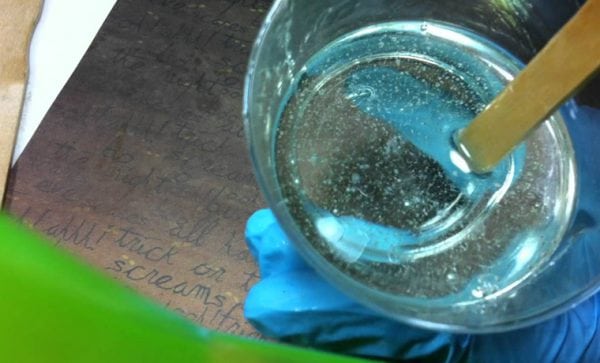

Usually, 40 ml of hardener is required per 100 g of epoxy, but the proportion may be different, depending on the manufacturer's recommendations. The resin mass needs to be slightly warmed up without removing from the packaging. To do this, it is placed in warm water (water temperature - 60 degrees) for 10 minutes. After spread the product in dry disposable dishes or other containers, which can then be discarded. For 3 minutes, the mass is thoroughly kneaded.

For direct work and obtaining the ideal result, it is necessary to observe the following conditions:

- the temperature in the room is 25-30 degrees;

- low humidity - up to 55%;

- absence or minimal content of dust, pollutants in the air, on the working area.

Other conditions will negatively affect the final result. Moisture is especially harmful to transparent epoxy - the resin deteriorates not only from direct ingress of water, but also from high humidity. All work surfaces are set horizontally in level, otherwise the finished product will be uneven. It must be remembered that the form will remain in one place until complete polymerization, and it must be placed where it is convenient. After pouring another layer, if possible, cover the product from dust.

The procedure is as follows:

- add the hardener to the mixed resin in the proper ratio;

- mix the product for 15 minutes, but without heavy movements;

- if there are air bubbles, they must be removed by immersing the mass in vacuum or by heating the resin with a burner flame (it is important not to overheat the mass above 60 degrees, otherwise it will deteriorate);

- remove the bubbles adhering to the surface of the resin with a toothpick - pierce them, it is also permissible to pour a little alcohol on the mass;

- leave the finished layer to dry.

During the first 30-60 minutes, it will be seen how high-quality the filling turned out to be. If the mixture exfoliates, the density of the components is not the same, the proportions are chosen incorrectly. It will also cause the appearance of surface stains, spots. Full polymerization lasts 24-48 hours, depending on the brand of epoxy and the thickness of the layer. It is not recommended to make it more than 1-2 cm, especially for beginners. Any contact with the uncured mass will result in rejection.

Acceleration of resin hardening is permissible. For this purpose, after initial curing (after 1-2 hours at +25 and above), you can transfer the form to the dryer at a temperature of +70 degrees. After 6-8 hours, the product will be ready. For the first time, it is not recommended to use portions of resin more than 200 g. It is on such a quantity that you can specify the operating procedure, pour time, and besides, the indicated weight is completely poured into one layer.

The time between pouring individual layers should not be less than 18 hours. Further, the surface of the previous layer is sanded with sandpaper with very fine grain, after which you can perform the subsequent application of the compound. The time until active use of the multilayer product is at least 5 days.