AK-511 paint is intended for marking on the road, which is required by the rules of the road, and helps to ensure the safety of drivers. In the use of paint has its own characteristics that must be considered when working.

- Paint purpose

- The composition and properties of the material

- Product Features

- Color schemes

- Preparation for work

- Application Methods

- Storage and safety

Paint purpose

Enamel for marking the road AK-511 is made in accordance with GOST R 52575-2006 and is used for applying safety lines on public roads. Enamel is intended for those routes where intense and moderate movement is observed; it is excellent for the following coatings:

- cement concrete;

- asphalt concrete.

Horizontal road markings made using paint are widely used in areas near warehouses, parking lots, parking lots, airfields. The black material is not used for marking roads, but for unmarking the old markings (it paints over it). In order to provide marking with retroreflective properties, additives are added to the enamel - special glass beads. According to GOST, it is permissible to apply funds on the carriageway of category 1–4 roads.

to contents ↑The composition and properties of the material

The composition of the marking enamel contains various pigments, fillers, diluted on an acrylic copolymer with the addition of modifying additives. Material properties are indicated in the certificate of conformity and other technical documentation. Here are the main ones:

- high brightness factor;

- providing excellent visibility for drivers in the dark and daytime;

- quick drying - in just 15-30 minutes;

- good grip;

- high wear resistance and hiding power;

- no damage during sudden changes in temperature.

Important! The markings applied to the road will last a long time - it is resistant to water, dirt, fuel and lubricants and other chemicals, salts.

When glass beads are added, the markings are clearly visible even in bad weather. This reduces accident rate on the road.

to contents ↑Product Features

Specifications reflect the basic parameters of AK-511 paint, which should be studied before using it:

- the created coating is smooth, even, with a uniform texture, without extraneous inclusions;

- viscosity according to the device VZ-246 viscometer at a temperature of +20 degrees - 80-160 s;

- solids content - 75%;

- coating adhesion - 1 b;

- enamel full drying time at a temperature of +20 degrees - 30 minutes;

- brightness coefficient - 70%;

- the density of the material is 1.4 g / sq. cm;

- milling degree - 70 microns;

- light fastness of the coating - 8 hours;

- resistance to the action of water - 72 hours, to the action of a solution of sodium chloride - 72 hours, to the action of gasoline - 20 minutes.

Color schemes

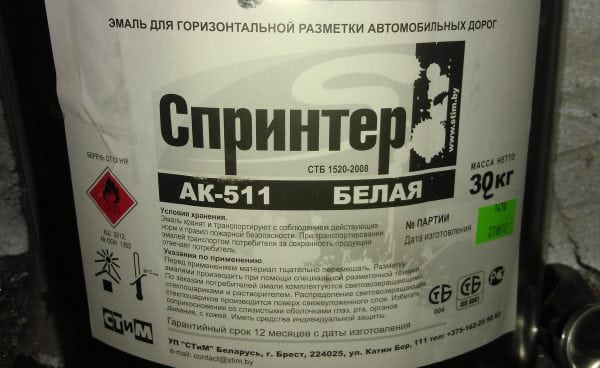

AK-511 paint is white, according to GOST it should not have extraneous shades, it is matte. AK-511 Sprinter enamel is also available, in which color pigments are added. Colors of paint - yellow, orange, black, red.

to contents ↑Preparation for work

Work with enamel should only be in dry weather. The coating is maximally cleaned of dirt and dust. Air temperature + 5 ... + 30 degrees, air humidity does not exceed 85%.

The paint is well kneaded before application until the residue completely disappears. To eliminate the bubbles after stirring, leave the material for another 10 minutes. Various diluents can be used for dilution. What to dilute is indicated in the instructions for use - you can use toluene, P-4, acetone, ethyl acetate, butyl acetate. The amount of solvent from the total mass of the material does not exceed 15%. If there is a break in work, the product must be tightly closed, and once again kneaded.

to contents ↑Application Methods

You can apply the product with a roller, brush, spray. The distance from the spray nozzle to the surface is 20-30 cm. The operating mode is selected depending on the brand of device. Usually enough 1-2 layers of paint. Consumption is 400-600 g / sq. m. Glass beads are mixed with paint at a rate of 300 g / sq. m cover.

to contents ↑On a wet road surface, application is not allowed, nor can the material be diluted with water, gasoline, kerosene. Washed equipment with toluene. Drivers will be able to use expensive 15-30 minutes after applying the enamel, depending on the air temperature (the higher it is, the faster the coating dries).

Storage and safety

The shelf life of the product is 6 months. It should be stored in tightly sealed containers, protecting from water, direct sunlight. Storage temperature - within –30 ... + 40 degrees.

Security measures are as follows:

- paint is toxic due to the presence of solvents in the composition, hazard class - 3, maximum concentration limit in the air of the working area - up to 150/50 mg / cu. m;

- Workers should wear gloves or apply protective pastes to their skin;

- respiratory organs must be protected with respirators or gas masks;

- fire safety measures should be strictly observed - do not smoke, exclude sparks;

- in case of fire, extinguish with sand, asbestos blankets, foam, water.

The material is produced by Khimprom-M LLC. Also on sale you can find paint from the manufacturer NPK "Paint". Enamel is available in containers of 20, 27, 55 liters.

Interested in paint AK-511 white.