White paints are used in painting, decoration, construction and everyday life. White zinc and titanium found application in all areas of artistic activity associated with the creation of a paint layer on the surface of the product or canvas. In construction, whitewash is used for painting surfaces and as a pigment for some water-soluble paints.

- White paints and the history of their creation

- White paint characterization

- Application

- Painting sequence

- Coloring metal products with white paints

- Professional Tips

White paints and the history of their creation

Much earlier than the appearance of zinc white, mankind learned to make lead white. This type of paint was known to the ancient Greeks and Romans. Lead white was used everywhere until the 19th century.

Due to the toxicity of white paint based on lead, humanity has not abandoned attempts to create alternatives to it. So zinc whitewash was invented. But, having appeared in 1780, they did not receive distribution, due to the high cost of the process of their production, and only 60 years later, relatively cheap white paints based on zinc were obtained.

Following this, in 1912 titanium whitewash was discovered. These paints first appeared in Norway. White titanium differs from other white paints in that they are completely non-toxic and have good covering qualities.

to contents ↑Thus, new titanium and zinc compounds replaced lead white.

White paint characterization

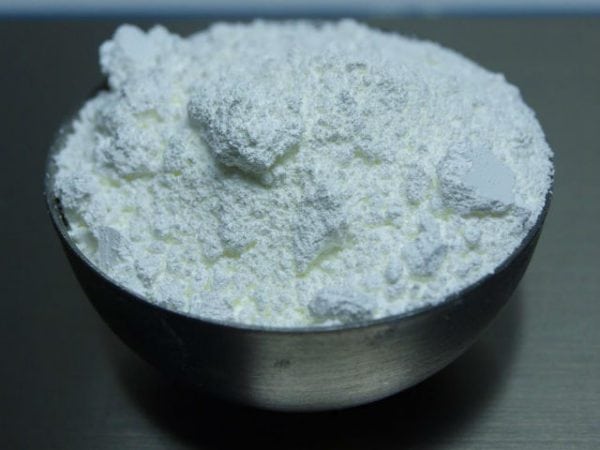

Zinc whitewash goes on sale in the form of ready-made or thick-grated paints. Thickly grated materials must be diluted with oil varnish before use. Other diluents are unsuitable for this purpose, since as a result the painted surface will acquire a yellowish tint.

For this material in its pure form, a snow-white color with a bluish tint is characteristic. The quality and whiteness of this material is completely dependent on the raw material from which the pigment was obtained. Store this product in a closed form, as it absorbs moisture from the environment. Zinc white pigments do not ignite and do not deteriorate under the influence of microorganisms.

This coloring material has a lot of positive qualities:

- Good resistance to direct sunlight.

- High level of compatibility with many colors in a colorful palette.

- Possibility of application in all areas of painting and arts and crafts.

- Low toxicity.

Zinc white has negative qualities:

- dry for a long time;

- differ in low covering ability;

- the paint layer created by white is prone to cracking;

- require a large consumption of oil solvents.

Dense whitened whitewash is used to obtain colorful compositions for coating wooden, metal and plastered surfaces of walls and ceilings.

Lead white had a pure snow-white color, which did not lose its brightness under the influence of sunlight.The positive qualities of these paints include:

- plasticity, which allowed the paint to maintain strength and not spill, even if it became necessary to roll the canvas;

- good resistance to moisture;

- ability to quickly dry the paint layer, after application to the surface.

Lead whitewash has the disadvantages that have made it less popular:

- high toxicity;

- do not mix with all paints;

- over time, the paint layer loses its brightness.

All these negative aspects have led to the fact that lead white is not used for industrial purposes.

White titanium is beneficial in that they:

- create a matte and very durable surface;

- able to withstand the effects of atmospheric moisture and direct rays of light;

- have the highest brightness of all modern white inks.

Titanium compositions have one drawback: when dried, they create a brittle surface of the paint layer.

to contents ↑The last alkyd paints appeared, they are the product of complex chemical synthesis.

Application

Due to the high toxicity, lead white is not used in everyday life. Oil-based zinc whitewash, alkyd and titanium compounds are used to paint surfaces in order to isolate them from moisture.

For painting plastered walls and ceilings, water-soluble paints based on zinc white are used. It should be noted that the walls are now rarely covered with white color, most often such paint is used to cover the ceiling.

to contents ↑

Painting sequence

The ceiling is painted as follows:

- The first thing that needs to be done before the start of the painting is to put on protective glasses, and gloves on your hands, and you should also cover your hair with a handkerchief or cap (this is done in order to avoid getting paint flowing from the ceiling into the eyes and on the hair).

- It is necessary to provide air access to the room. After staining, the room should be well ventilated.

- To clear a ceiling of layers of the old cracked and falling off plaster, paint, dust, grease, drips.

- Apply new layers of plaster, level the ceiling. Painting is carried out only on a perfectly flat surface.

- Grout the surface with sandpaper until the ceiling acquires the desired smoothness.

- A surface having enhanced absorption properties is covered with two layers of drying oil. In the interval between coatings, the primers are allowed to dry.

Coloring metal products with white paints

There are two industrial methods of applying whitewash of any kind on the surface of metal products. The first of these involves the complete immersion of a metal part in a container containing zinc or titanium white (lead white is not used for industrial purposes).

The second method of industrial painting the surface of the metal involves applying a coloring layer of zinc, alkyd or titanium compounds to the entire area of the product using a spray gun. For this purpose, solvents are added to the paint in the required amount, after which the coloring composition is filtered. Only then can you start applying the paint coat.

In everyday life, staining is done using a roller or brush (cars are not allowed to be painted in this way). Also, white stain is not used for coloring household items.

to contents ↑Professional Tips

- Staining materials must be stirred before use. If they are thickened, you can add natural drying oil to zinc white or oil varnish. Oil paints are diluted with white spirit, turpentine or a special solvent for oil paints (all this can be purchased in specialized stores selling goods for artists).

- Paints are applied to a primed surface.

- High-quality staining can be achieved by applying two layers of paint coating.

- A new coat of paint is applied only to a well-dried surface, otherwise the film formed by the previous layers will be broken.

- If lead whitewash is used in artistic activities, safety precautions must be taken and the room periodically ventilated.

White paints are used in everyday life more often than all others.

This is due to the fact that they are mixed with other colors to create the necessary shades. It is important to remember that it is worth combining only those materials that are created on the same basis.