The emergency route is the direction of movement of people during emergencies, along which they can get into a safe area. Such sites necessarily comply with fire safety requirements, which is taken into account when carrying out finishing work and acceptance of premises by services. There is even a special paint for the KM0 escape routes, which is recommended for use by the fire department.

- Purpose of paint and basic requirements

- Application of paints

- KM paint 0

- Akterm KM-0 - non-combustible paint from a Russian manufacturer

- Material scope

- Composition and properties

- Technical specifications

- Preparatory Activities

- The main stage of applying Akterm KM-0

- KM 1

- KM 2

- KM 3

- KM 4

- KM 5

- Application

- Security measures

Purpose of paint and basic requirements

In many institutions - kindergartens, schools, hospitals - the walls of the evacuation passages are still painted with rather dangerous paints and varnishes. In the composition they contain a number of flammable additives, which significantly increases the risk of a major fire during fire. Under the new rules, civilian facilities, as well as stairwells, elevators, and vestibules, must be painted with a non-combustible, fireproof paint. The same standards apply to hotels, hostels, cultural buildings, premises of banks, offices.

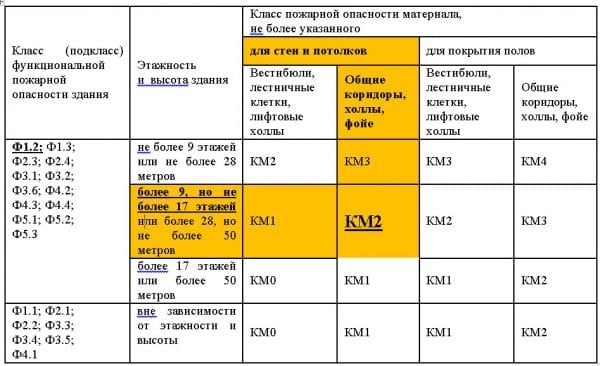

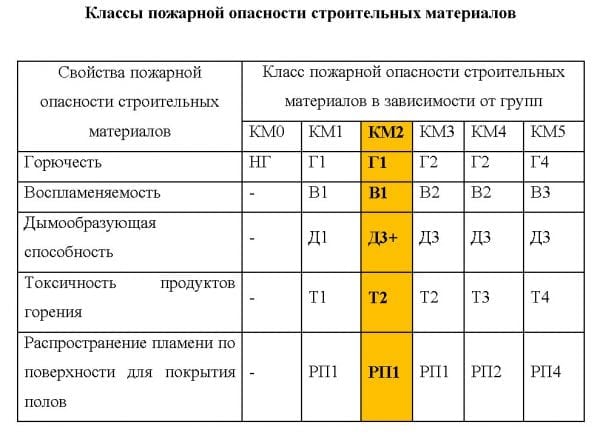

For the gradation of materials hazard classes have been developed (from KM 0 to KM5), while only KM0 class paints should be used at these facilities.

Why do we need such materials? If the coating is a similar product, the flame will not spread. Also the advantages of paints KM0 and KM 1 are as follows:

- form little smoke;

- non-flammable or non-flammable;

- non toxic in smoke.

to contents ↑Fire-retardant paint must comply with GOST standard, have the necessary certificates. Typically, water based paints are paints, but not every water-based material has similar properties.

Application of paints

Application of funds is allowed on the surface of concrete, stone, brick, gypsum, they are suitable for plastered substrates. NG paint (non-combustible) gives a white coating, but it can be tinted in any desired color, so it acts as an interior. For tinting, any pastes or dry pigments for aqueous emulsion products are suitable. The use of the material is permissible on the walls, ceiling, floor indoors.

There are a number of recommendations for the use of paints, depending on the class of incombustibility:

- Entrance halls, halls, cages of stairs of public institutions - KM0 ceilings, KM1 floor.

- Common corridors, halls of the lobby of public institutions - ceiling, walls - KM1, floor - KM2.

- Entrance halls, halls, stairwell cells in buildings of less than 9 floors - ceiling, walls - KM2, floor - KM3; in buildings of 9-17 floors - KM1 for walls, ceiling, KM2 for floor, in buildings of more than 17 floors - KM0 and KM1, respectively.

- Common corridors, foyer halls in buildings of less than 9 floors - ceiling, walls - KM3, floor - KM4, in buildings 9-17 floors - KM1 for ceiling, walls, KM2 for floor, in buildings of more than 17 floors - KMO and KM1, respectively.

KM paint 0

The composition includes water, fillers, water glass, various additives.It is this tool, due to the presence of liquefied glass fibers, that is completely non-combustible; it is intended for effective fire protection of walls and ceilings along the evacuation routes of citizens. Mandatory KM0 is used in rooms with increased fire safety requirements - in child care facilities, hospitals, clinics, in rooms with a capacity of more than 300 people. Its combustibility corresponds to the class of NG (non-combustible), the flame propagation index is 0.

The paint has high adhesion and is used for application on such surfaces:

- drywall;

- concrete;

- putty and plaster;

- brick;

- tree;

- cullets;

- metal.

Since the composition refers to water-dispersion, the product withstands operation even with high humidity. It is environmentally friendly, non-toxic, odorless, highly opaque, vapor permeable. The coating can be washed, it is pleasant to the touch, silky matte, resistant to abrasion. Here are the technical specifications that paint from different manufacturers must meet:

- viscosity - 100 s with a VZ-4 viscometer;

- dry residue - 60%;

- drying time to the 3rd degree - 60 minutes at a temperature of +20 degrees;

- application conditions - humidity up to 80%, temperature + 5 ... + 30 degrees.

Akterm KM-0 - non-combustible paint from a Russian manufacturer

Decorative non-combustible paint “Akterm” KM0 (NG) is a paint and varnish material that is designed to design escape routes. After drying, it forms a fireproof, harmless to humans coating, additionally having sufficient aesthetic properties. The fire hazard class of the paint is 0, the combustibility class is NG (non-combustible).

to contents ↑Material scope

LKM is intended for the prevention of the spread of fire when various surfaces are ignited in these types of rooms:

- stairs

- Lobbies

- corridors;

- halls;

- elevators;

- basements;

- warehouses, including fuel and lubricants;

- refueling;

- garages;

- shopping and business centers;

- houses of culture;

- the shops;

- cafes, restaurants;

- movie theaters, etc.

Ackerm paint is used to color the evacuation routes of people in different buildings, structures, and is also used in other places where it is necessary to prevent the spread of flame. This product is suitable for:

- drywall;

- brick;

- a tree;

- stone;

- glass;

- concrete;

- plaster.

Composition and properties

This water-dispersion paint is made on the basis of an inorganic aqueous binder, improving additives, modifiers, fillers, dyes, fungicides, silver ions. After drying, it allows you to get an excellent matte finish, pleasant to the touch, silky. The dried film has the following properties:

- resistance to UV rays, detergents and disinfectants, water;

- high strength, wear resistance, long service life;

- lack of shrinkage, cracking, detachment;

- sun reflecting ability;

- antiseptic and antifungal qualities.

After application, the paint forms a microporous (breathable) coating, which is environmentally friendly, 100% harmless to humans. LKM has white color, but can be tinted in any shade at the request of the user.

to contents ↑Technical specifications

Ackerm paint is characterized by the following technical data:

- solids content - 53%;

- frost resistance - 2 cycles;

- drying time to the third degree - 60 minutes;

- film resistance to static action of water - 48 hours, detergents - 48, light - 72;

- adhesion - 1 point;

- the degree of moisture absorption of the film is 0.5%;

- impact strength - 0.5 m;

- hiding power - 150 g / sq. m;

- hardness on the M-3 device - 0.35 conventional units;

- density - 1.4-1.7 g / cu. cm;

- viscosity according to VZ-4 - 30 s.

After drying, the film should be smooth, homogeneous without any foreign inclusions, wrinkles, potholes and sagging. Its service life is up to 15 years. The paint consumption for creating a two-layer coating is 240-300 g / sq. m, it depends on the type of base, its porosity and roughness.

to contents ↑

Preparatory Activities

The surface before work needs to be washed, cleaned of dirt, debris, remove old coatings, dust off.Immediately prior to staining, the base should be primed with KM 0 Primer and dried. The paint must be mixed well without dilution with water. The working conditions are as follows:

- temperature - + 10 ... + 35 degrees;

- humidity - up to 80%.

The main stage of applying Akterm KM-0

Paint is applied with a brush, roller, spray in 2 layers. Intermediate drying of the layers lasts 2 hours at room temperature. Until completely dry, the surface should be left unused for 48 hours. If the room temperature is below +20 degrees, the drying period may be delayed for a longer time. If necessary, any pigment paste based on water can be used for tinting the composition.

Do not mix paint with other materials, its properties with respect to incombustibility will begin to deteriorate. When applied to varnished substrates, the surface cracks. Staining the bases in dark tones often leads to the appearance of lightened areas in places of impacts and scratches. If a separate area of the coating is damaged, it must be cleaned to a strong layer, prepare the surface and apply the paint again.

to contents ↑KM 1

This tool can also be used for coloring evacuation exits, in its composition is a base of acrylic dispersion, additives and pigments. It is tinted in any shade. By technical characteristics, the paint differs from the previous viscosity (100 s). It has the following fire safety standards:

- combustibility - G1;

- smoke formation - D1;

- flame spread - RP1;

- flammability - B1 (hardly flammable);

- toxicity of combustion products - T1.

to contents ↑Typically, the material is used to paint escape routes in structures and buildings that are not related to those listed above for KM0 paint. It is applied to any surface and is intended to reduce the speed of flame propagation. It can serve as a decorative coating, durable, resistant to wear and washing.

KM 2

Means of this category are acceptable for painting floors of evacuation passages, as well as corridor walls, the lobby of rooms in buildings up to 50 meters high (9-17 floors). KM2 paint is moderately flammable, belongs to class B2. According to the degree of flame spread, it refers to RP1 - non-spreading flame. The combustibility class is G1 (low combustible), toxicity - T2 (moderately hazardous), smoke emission ability - D2.

KM 3

Paints of a class below KM2 are used only for coloring floors. KM3 class material has such fire characteristics:

- flammability - G2 (moderately flammable);

- flammability - B2;

- smoke formation - D3 (high smoke-generating ability);

- toxicity - T2;

- flame spread - RP2 (weakly spreading).

KM 4

The fire safety parameters of KM4 paint are as follows:

- flammability - G3 (normally flammable);

- flammability - B2;

- smoke formation - D3 (high smoke-generating ability);

- toxicity - T3 (highly dangerous);

- flame spread - RP2.

KM 5

This tool is not used for staining escape routes and exits. The fire safety parameters of the paint are as follows:

- combustibility - G4 (highly combustible);

- flammability - B3 (flammable);

- smoke formation - D3;

- toxicity - T3 (extremely dangerous);

- flame spread - RP4 (highly spreading).

Application

If plastering was carried out on the walls, ceiling, it is recommended to paint them after 2 weeks, not earlier. Surfaces should be completely cleaned if they have already been whitewashed, silicate or adhesive. You also need to remove dirt, dust, rust, grease stains. Pits and other defects must be putty, but not with latex putty (it causes a loss of incombustibility). Before full painting, primed walls with water with KM1 paint in an amount of 10-15% of the total.

The basic composition can be diluted with water, but not more than the viscosity that is indicated in the technical specifications. Any other substances, except water and tinting, cannot be added! Apply KM0, KM1 and other paints with a roller, brush, spray in 2 layers. After each layer, intermediate drying is performed for 30-60 minutes, depending on the temperature. Full drying is carried out during the day. Further wall washing is acceptable after 14–28 days. Paints have a low consumption - 150-200 grams / square meter. It is about applying the product in one layer.

to contents ↑

Security measures

Dyeing should be done in work clothes, gloves, and when sprayed, in a respirator. If the product gets on the skin, in the eyes, they are washed extensively. Waste is disposed of as household waste; paint should not be drained into the sewer.

I didn’t understand a bit whether it is possible to paint the type of km2 enamel on the 9th floor of the wall near the door to the apartment?

KM2 can be painted on the walls on the 9th floor, and KM3 is only a floor