Various parts and elements of mechanisms that are made of metal and are operated in an aggressive environment or high humidity require a special protective coating. A product such as EP-969 enamel is perfectly suited for these purposes - it improves the technical performance of the products used.

Enamel scope

Paint and varnish agent EP-969 enamel is a two-pack material, including a base and hardener, designed to create an electrical insulating and waterproofing coating.

If you follow all the recommendations for applying paint, the products in use will be reliably protected for 3 to 5 years, and sometimes even more (this depends on the specific conditions of their work). The paint provides an improvement in the decorative properties of the surface, which acquires a green color, becomes smooth, smooth, without roughness.

Enamel is sold by many specialized stores and companies, has all the necessary certificates of conformity. The product is packaged in a container of fifty liters, to which a hardener is attached.

The scope of the product is diverse, it is applied to protect:

- steel pipes of heating systems;

- other types of pipelines;

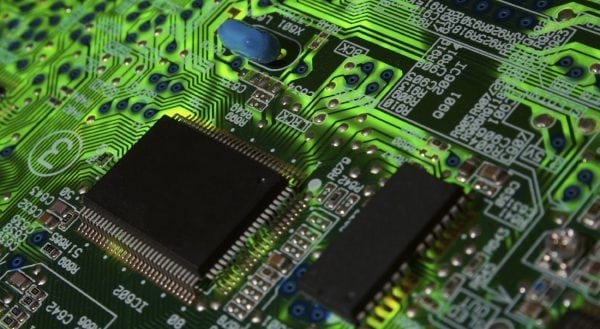

- relay parts;

- microcircuits - ceramic, ferrite;

- products in the radio industry;

- products in instrument making;

- engineering structures.

Especially shown is the use of paint on products that operate at temperatures from 0 to -60 degrees, from 0 to +150 degrees. It is recommended to apply enamel on those surfaces that are operated at high humidity - up to 96%.

to contents ↑Product Specifications

As part of the product - pigments, various fillers, the basis is epoxy resin. This gives the EP-969 enamel the following properties: anticorrosion, moisture resistance, wear resistance.

Among the technical characteristics, it is worth noting the following:

- color - light green, semi-matt;

- drying period: 24 hours at a temperature of 20 degrees, 2 hours - at 120 degrees;

- consumption per square meter of surface - up to 120 grams;

- layer thickness - up to 40 microns;

- the required number of layers is two;

- working viscosity (measured with a VZ-4 viscometer, 4 mm nozzle) - 15 - 16;

- the ability of enamel to be applied to the surface after the introduction of the hardener - 8 hours.

If necessary, the product can be diluted - for this purpose, it is recommended to introduce solvents R-4, R-5.

to contents ↑Instructions for use

Before applying the paint, the surface is cleaned of dirt, oil, grease, dust. The dilution order is indicated in the instructions: it is necessary to mix the enamel in the container, combine with the hardener at the rate of 45 g of base per 12 kg of hardener. After the introduction of the second component, the agent should be thoroughly mixed again, left for an hour. If the enamel is too thick, use the above solvents.

Application is carried out using:

- brushes;

- roller;

- filling;

- pneumatic sprayer.

Do not use paint at temperatures below +15 degrees - this may impair performance. After a day, a second coat can be applied.Keep the material out of the reach of fire, sunlight, tightly closing.

If the product gets on the skin, just wash it with soap. At home, you should use the paint with caution, if possible entrusting the work to professionals.