Organosilicon paints are widely used in production. Their feature is high resistance to temperature and other aggressive factors. An example is enamel KO-174, as well as some other paints from the same group.

- Purpose of enamels KO-174, KO-198

- Product Features

- Surface preparation

- Material preparation

- Staining technique

- Safety requirements

- Features of the enamel KO-168

Organosilicon enamels and varnishes are used for painting surfaces of iron and other metals in order to protect them from exposure to chemicals, gases, temperatures, precipitation and extremes. They include a number of special additives that provide the desired properties.

KO-174 paint is moderately heat-resistant, while some other silicone enamels withstand temperatures up to +1000 degrees. The advantage of paints of this group is the protection of products from corrosion, as well as the possibility of application on other materials.

to contents ↑Purpose of enamels KO-174, KO-198

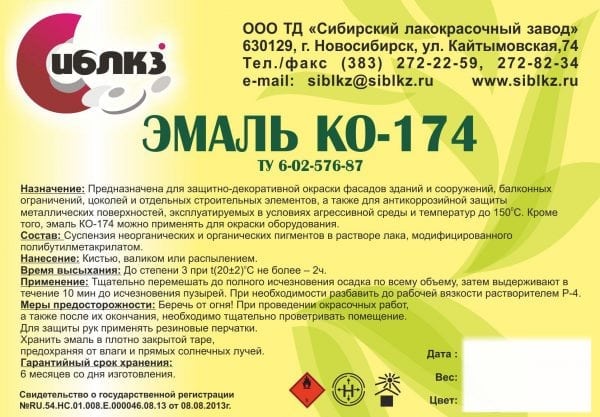

Weatherproof facade enamel KO-174 is used for decorating building facades, as well as for applying to various structures, structures, concrete products, asbestos cement. This material can also be used for painting machinery, equipment. Resistance to atmospheric conditions allows you to operate the paint even in the Far North in harsh climates.

KO-174 creates a coating that, thanks to high-quality pigments, looks quite attractive. The properties of the obtained film are as follows:

- Excellent grip.

- Water resistance, impermeability to moisture.

- Frost resistance (up to 90 freezing and thawing cycles).

- Heat resistance - the ability to withstand temperatures up to +150 degrees.

- No burnout under the sun.

The product is available in different colors, depending on the added dye. Possible shades are gray, blue, white, black, green. There are certificates of conformity for each batch.

Enamel KO-198 organosilicon is intended for other purposes. The description indicates that it is used to protect the metal from the action of mineral groundwater, as well as from chemicals:

- saline solution;

- nitric acid;

- of hydrochloric acid;

- sulfuric acid, etc.

Such properties make it possible to paint tanks, tanks, containers, equipment for chemical production with this material. The tool has anti-corrosion and frost-resistant properties, so it is applied to foundations, reinforced concrete supports, railway platforms, bridges. Enamel can be used in hot tropical climates. Paint color - red, brown, blue, yellow, black, white, gray.

The main difference between these colors is in the purpose. If the first is used in a cold climate for painting facades and structures, the second is intended to protect the metal from the action of aggressive substances and can withstand work in a hot climate. Both products are available in small and industrial containers weighing up to 50 kg.

to contents ↑Product Features

Each enamel, the technical characteristics of which are given below, after drying, gives a beautiful, even film, which is homogeneous, without any impurities. Other technical parameters of enamels are given in the table.

| Indicator | KO-198 | KO-174 |

|---|---|---|

| The share of non-volatile components | 30% | 50% |

| VZ-4 viscometer viscosity at +20 degrees | 15-30 s | 20 s |

| Dry to 3 degrees at +20 degrees | 20 minutes | 1 hour |

| TML hardness | 0.3 cu | 0.3 cu |

| Film Strength on Impact | 50 cm | 40 cm |

| Adhesion | 2 points | 2 points |

| Heat resistance at +300 degrees | 5:00 | – |

| Heat resistance at +150 degrees | – | 3 hours |

| Consumption per m2 | 100-150 g / sq. m | 100-110 g / sq. m |

| Layer thickness | 15-18 microns | Up to 40 microns |

| Number of layers | 2–3 | 1–2 |

| Working temperatures | –60 ... + 300 degrees | –30 ... + 150 degrees |

Surface preparation

Before applying any of the listed paints, the surface should be properly prepared. To do this, it is cleaned of grease, oil, dirt, dust, rust is removed. Old paint is also cleaned off. Preparatory work is done using a sandblasting machine or manual processing, depending on the dimensions of the product. If the surfaces will be operated at moderately hot temperatures (up to +100 degrees), only a rust converter can be used. The rust stains that remain after the completion of all work must be treated again with a converter, then rinse well.

At the end of the preparatory phase, the base is wiped with degreasers (solvent, xylene), thoroughly dried. This should be done 6 hours before painting, if the products are in an open area, or after 24 hours if they are located indoors.

to contents ↑Material preparation

The enamel KO-174 is thoroughly mixed using a mixer, a stick, until the mass becomes homogeneous, there will be no sediment in it. Then hold the paint for 10 minutes before the release of air bubbles. The viscosity should be different, depending on the application method:

- for a roller, brush - 25–35 s;

- for a spray gun - 17–25 s.

If the viscosity is exceeded, solvents are added - solvent, xylene 30% or less. During breaks in painting work, the material is firmly closed, then mixed again, allowed to stand for 10 minutes.

Enamel KO-198 has differences from the previous one in working viscosity and method of application. It is applied with a spray gun, while the viscosity should be 12–20 s. The same solvents are used for dilution. The rest of the procedure for preparing the material is similar.

to contents ↑

Staining technique

Enamel KO-174 is applied by pneumatic spraying using a roller or brush. Staining is carried out in at least 2 layers, the temperature during operation is from –30 to +40 degrees, humidity is up to 80%. If the temperature is minus, you must ensure that it is above the dew point by 3 degrees or more. When working with a spray gun, choose a device with a nozzle of 1.8–2.5 mm, set the pressure to 1.5–2.5 kgf / sq. cm, the distance to the base is 20-30 cm.

Brush usually paint the edges, ends, seams. Staining of the metal should be done in cross layers, the drying time of each is 30-120 minutes, the degree of drying is checked "for sticking." If the temperature is minus, the drying time is extended by 2-3 times. The bases of other materials are painted in 3 layers, each must dry for 2 hours. Final drying of any surface lasts at least 24 hours.

Enamel KO-198 has few differences in the staining technique. The difference is only in the application method - mainly a spray gun (pneumatic spraying) is used. The parameters of humidity, temperature, spray gun settings are similar. If the product is small, a dipping method can be used. The roller and brush are used only for painting hard-to-reach spots. Other important details during operation:

- Metal products are painted on 2-3 cross layers, each is dried for 20 minutes, the final - 4 hours at a temperature of +20 degrees, humidity up to 65%.

- The coating dries to degree 3 within 4 hours, fully polymerizes and hardens in 24 hours.

Safety requirements

Both types of enamels are toxic, as solvents are included. The latter belong to the third hazard class. Painting work is best done outdoors or well ventilated.Workers should wear respirators, gloves. When painting surfaces in enclosed spaces, pits, wells, a gas mask should be worn.

to contents ↑It is important to protect the enamel from the effects of open flame, heat, as they are flammable and flammable. In the working area must be present means to extinguish the fire, it is strictly forbidden to smoke near the place of work. Enamels are stored at a temperature of –40 ... + 40 degrees.

Features of the enamel KO-168

KO-168 paint is used for painting facades of buildings and structures. This material has high anti-corrosion properties, is hydrophobic, resistant to atmospheric factors. The product is available in different colors - green, black, blue, white, gray, red.

Enamel KO-174 is one of the first developed materials related to organosilicon. It was developed over 40 years ago and is still widely used. But the product has a significant minus - pigments are quickly washed out of it, the color fades. Enamel OS-12-03 has now been developed, which repeats a number of properties of KO-174, but surpasses it in resistance to the action of water, the sun. It is the OS-12-03 enamel that is used more and more often, it gradually “captures” new areas of use.