Protection of materials from corrosion is a guarantee of their long service life. For this purpose, various coatings are used, thanks to which the surface becomes resistant to the action of damaging factors.

- Description and purpose of enamel

- Enamel composition

- Specifications

- How to apply enamel

- Proper storage

- Breeding order

- Enamel application

- Consumption rate

- Basic mistakes when using

HV-0278 primer-enamel is a high-quality metal protection agent, due to which the product life is prolonged in any climatic conditions.

Description and purpose of enamel

HV-0278 primer-enamel is a type of primer that additionally has the properties of an enamel, a rust converter, that is, it combines all three means in one. This paint and varnish product is not a novelty in the market: the manufacturer Antikor-LKM has been producing it for more than 15 years.

Scopes of a primer are various:

- Covering any structures in industry, everyday life.

- Painting of machines, units that are exposed to steam, gas, chemicals, reagents, liquids with temperatures up to sixty degrees.

- Painting of metal surfaces (steel, cast iron) on which there are soot zones.

- Work on sections of rust, the depth of which does not exceed 100 microns.

- Processing lattices, garages, car parts, fences, gates, stairs, products with large dimensions and a complex profile.

- Primer for parts that do not require a decorative coating.

- Creating a base for refractory coatings.

The cost of soil-enamel is about 120 rubles per liter, produced in packs of 1 - 25 liters. The service life of the material after creating the coating film is about 5 years. If necessary, you can purchase more modern tools that last up to 15 years, but their cost is much higher. In recent years, the manufacturer began to produce XB-0278 primer-enamel with the addition of pigments - you can buy a tool in black, blue, blue, gray, brown, yellow.

to contents ↑Enamel composition

The chemical composition is represented by the main component - perchlorovinyl resin, a number of additional fillers. This resin is used in the manufacture of pipes, bathtubs that regularly come in contact with an aggressive environment, while creating varnishes and paints with corrosion protection.

Other enamel components:

- epoxy resin;

- alkyd resin;

- pigments

- plasticizers;

- corrosion inhibitors and rust converter.

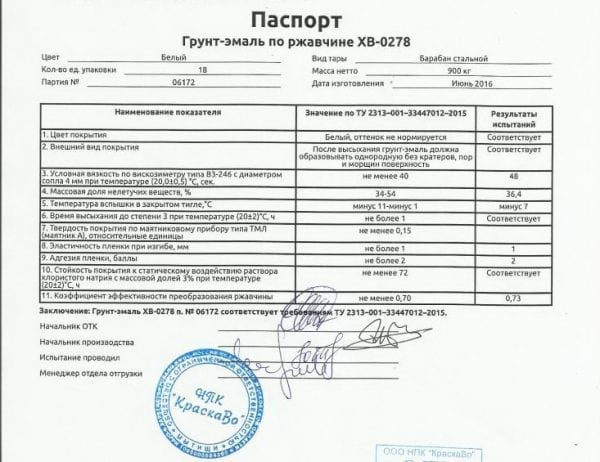

Specifications

The paint and varnish product is produced in accordance with GOST, its composition and technical specifications are approved by official certificates. The description of the product indicates the specific properties of the enamel itself, the quality of the resulting protective film after application.

The main indicators of primer-enamel are as follows:

- conditional viscosity - VZ-246;

- the amount of non-volatile substances - 35% in non-ferrous products, 31% - in black;

- consumption rate per 1 m2 - up to 150 g;

- the drying time of the product is 1 hour (temperature - about 20 degrees).

The resulting film is dense, uniform, matte. Her technical indicators:

- layer thickness - 20 - 25 microns in the first, 20 - 40 - in subsequent ones;

- the number of layers on the product is two to three;

- the degree of milling of the layer is not more than 40 microns;

- bending elasticity of the coating - from 1 mm;

- film adhesion - 2 points;

- hardness according to the pendulum device - 0.15;

- resistance to sodium chloride 3% - from 72 hours;

- rust converter efficiency (coefficient) - 0.7.

How to apply enamel

Priming should be done after preliminary preparation of the surface, which may be rusty. Loose rust should be thoroughly rubbed before separation. It is necessary to remove the remainder of the previous coating, scale, dust, dirt, using solvents.

to contents ↑Proper storage

In order for the coating to be of high quality, the storage conditions of the product must be observed. It can be transported by any means of transport, but the air temperature should not exceed 30 - 35 degrees Celsius.

to contents ↑During transportation and storage, strict observance of the conditions for the protection of enamel from atmospheric precipitation is required. Storage does not allow exposure to sunlight or moisture. The container is tightly closed during storage. Permissible storage temperature: from -25 to +30 degrees. Compliance with the conditions guarantees excellent properties of the product up to six months from the moment of production.

Breeding order

How to dilute enamel? For dilution using solvents R-4, R-4A. The same means can be used for preliminary preparation and cleaning of the surface from pollutants. It is permissible to use diluents R-670A, R-670.

Specific dilution rates are not indicated, the viscosity of the finished product is determined by the application method. When applied directly by roller or brush, the mixture may be thicker than when sprayed from a spray bottle.

to contents ↑The solvent is added in small portions, each time thoroughly mix the mass. After applying the primer to the surface, the solvent evaporates quickly, and the coating remains strong. You need to work with solvents by wearing a pair of gloves, protecting the respiratory system with a respirator, and skin with thick clothes.

Enamel application

Apply XB-0278 primer-enamel in different ways:

- airless spray;

- pneumatic spray;

- roller;

- with a brush;

- dipping into the product.

Air temperature during work: from -10 to +30 degrees, humidity - 80%. The first layer should be dried for 1 to 2 hours (temperature - twenty degrees). The remaining layers are applied every hour. Two or three layers are sufficient to provide a stable coating, the first serving as a rust converter, the second as an anti-corrosion primer, and the third as a decorative coating.

to contents ↑Consumption rate

Typically, the consumption is not higher than 100 - 150 g / square meter of surface (the figure is for the first coat of primer). Subsequent layers will require a little less enamel - up to 100 - 120 g.

Basic mistakes when using

Most often, users allow such erroneous actions when working with a primer:

- Application of only one coat. Some to save only one layer of the product - this is the wrong decision. Two or three layers are necessary according to the instructions to ensure proper coating quality. Part of the enamel is absorbed into the rust, and solid components remain on the surface. Achieving a good protective film will not work.

- Dry spray. This method is suitable if an experienced specialist will perform the work, and the equipment will be specially configured. Otherwise, the adhesion and resistance of the coating will decrease.

- Use of unsuitable solvent. You can use only those tools that are indicated in the instructions and are compatible. Other solvents will violate the properties of enamel, will dry for a long time. White spirit can not be used for primers!

- Early use of the product.After completing the coating, you should wait for the complete polymerization as the solvent dries and the primer itself. The quality of the film will otherwise be impaired.

- Application on a smooth surface. To ensure good adhesion (adhesion), the surface should be rough, but free of contamination. Enamel is specially designed for surfaces with rust. Smooth materials should be pre-treated by roughening.

Compliance with all the tips and the implementation of staining strictly according to the instructions will allow for a long time to preserve the integrity of the products, protect them from corrosion.