Glaze paint is a translucent coating that is used to protect and decorate various surfaces. Its versatility lies in the fact that it can be applied:

- as a finishing coating on plaster or a separate material;

- on textured and on a flat surface;

- for exterior and interior use.

The only factor that limits its application is the presence of certain skills and work experience.

When finishing a smooth surface with this composition, you can get not only color uniformity, but also a variety of its shades. Mixing the color palette gives the effect of a smooth transition, forming fancy patterns that cannot be reproduced or repeated. This allows you to create a unique design in the interior of the room.

Applying such a varnish on the textured surface of the wood gives it a shine and slightly smooths the texture. But on the plaster, paint, on the contrary, emphasizes relief and creates volume.

to contents ↑Varieties of materials

Materials for glazing are distinguished by composition and purpose.

- paints for interior use: acrylic, oil;

- paints for exterior decoration.

Acrylic coatings for interior use have the following characteristics:

- lack of an unpleasant smell;

- moisture resistance;

- resistance to fading;

- antistatic effect, not allowing to accumulate on a dust surface;

- high speed of drying, component from 2 to 4 hours;

- lack of toxic and poisonous substances.

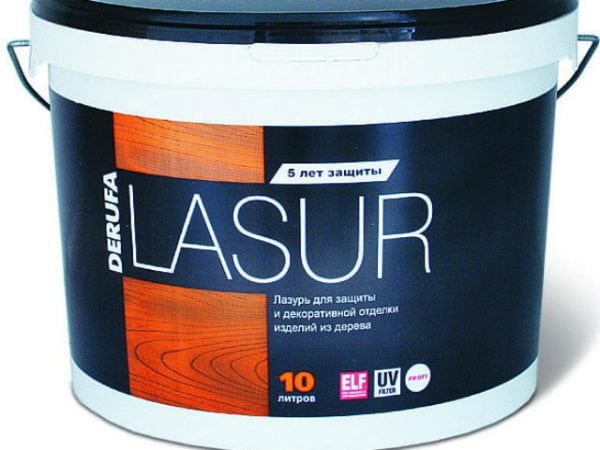

Some companies produce glaze antiseptics that prevent the propagation of pathogenic microflora on treated wooden surfaces and walls.

Oil-based coatings have the following advantages:

- wear resistance;

- ability to withstand mechanical loads;

- resistance to a sharp change in temperature;

- moisture resistance;

- security.

The disadvantage of this decorative composition is its long drying time.

Finishing for outdoor work is characterized by properties such as:

- frost resistance;

- moisture resistance;

- resistance to UV rays;

- the ability to withstand low and high temperatures, as well as their change;

- ability to withstand the reproduction of fungal microflora.

To varnish for glaze of external objects strict safety indicators are not shown. Therefore, their processing of walls or other surfaces indoors is undesirable.

to contents ↑Features of the preparatory phase

In preparation for glazing the surface of wood, you need to carefully clean its old coating with a building hair dryer or spatula. If there are various irregularities or cracks, then it is necessary to apply a layer of putty on the wood, wait for it to dry completely and sand it.

Walls are free of paint with sandpaper or sandblasted.If it is impossible to completely remove the layer of old paint, it can be well treated with abrasive paper and wiped with a dry cloth. If there are oil stains on the surface, they must be treated with a solvent, and then with clean water.

Damaged plaster must be puttied, sanded and primed before glazing.

to contents ↑As a result, after processing, a perfectly smooth and clean surface should be obtained.

Coating

It is impossible to work with decorative varnish or paint at high humidity, air temperature below + 10 ° C and above + 30 ° C.

Glazing compositions are applied to the walls using a sponge or a specially designed mitten. Before starting work, you should conditionally break the wall or other surface into squares of approximately 1 m2, and apply a decorative coating in stages on each of them. To obtain a bright color, 2 or 3 layers of glaze are applied. To get a blurry pattern on the plaster, dilute it with water.

Apply decorative varnishes and paints with large strokes directed in different directions, avoiding the formation of direct joints. When processing large volumes of wall surfaces, it is better to work together. One master applies the composition, while the second handles the joints by shading.

Wood glaze can be carried out:

- spray gun;

- sponge;

- with a brush.

Depending on the type of paint, its first layer is best diluted with oil, water or a solvent. This will improve wood adhesion by penetrating deeper into the wood.

It is possible that after the first treatment the surface becomes rough. This is eliminated with fine sandpaper, and then another layer of undiluted glaze is applied. If the wood surface is too porous, another coat of varnish may be needed. After this, care must be taken that within three days moisture does not get on the surface and the temperature does not drop below + 10 ° C.

to contents ↑Surface Care

Despite the fact that the varnish or paint is completely fixed on the plaster after 2 weeks, it can only be washed a month after processing. To do this, use a warm aqueous solution and a soft sponge. Do not allow oil, solvents or other aggressive chemicals to enter the surface, which can change the color of the paint or disrupt its integrity.

The wooden surface on which the glazing antiseptic is applied is quite resistant to adverse factors. The paint allows you to preserve its structure and does not lose its color for a long time.

Using a glazing coating that is applied to plaster and wooden surfaces to create an original room design, they can be reliably protected from moisture, mold and destruction. A wide selection of colors makes it possible to choose the right option to implement all your ideas.