There are special paints and enamels that are designed to protect boats, ship bottoms from moisture. In shipbuilding, such materials are indispensable, because they significantly increase the service life of products. A popular tool of this type is the HS-436 enamel - it is used specifically to protect the underwater part of ships from destruction.

- Enamel Description

- Scope of application

- Composition, cost and properties

- Technical specifications

- Application Technique

- Safety and storage

Enamel Description

XC-436 paint is a two-component vinyl-epoxy-based material that is used to paint the steel surface of the vessel - its bottom, hull. It is indicated to protect the metal from corrosion, which inevitably appears from being in water. The coating also reliably protects the base from harmful effects:

- fuel oil;

- oils;

- salts;

- gasoline and other petrochemical products.

The enamel film is high strength, it retains properties for at least 4 years, subject to the staining technology (in four layers). A coating made in three layers should be renewed every 2 years. The material is produced in accordance with TU 2312-011-60414707-2014.

to contents ↑Scope of application

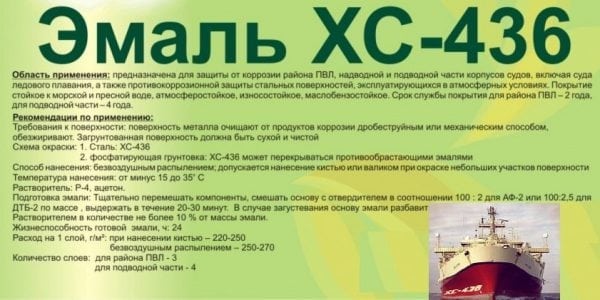

The paint was created specifically for application to ship hulls - in the area of immersion in water, as well as in the variable waterline area (at the interface between the air and water). Due to its high strength, the coating can be used even in ice waters, therefore it is used on icebreakers.

to contents ↑XC-436 is also widely used for painting port facilities, bridge supports, locks, moorings, landing stages. The material is excellent for application to underwater parts of pipes. They can also cover the internal parts of the hulls, individual sections in the hold.

Composition, cost and properties

The composition of the material includes the basic composition and hardener. Enamel contains various fillers, target additives, pigments to give the desired color (green, red-brown, black), which are diluted in epoxy-vinyl resin.

The paint is packaged in containers of 25 and 50 kg, in small packaging is not produced. Due to the presence of solvents, the material itself has a sharp unpleasant odor, after curing it ceases to stand out. The most famous enamel manufacturers:

- Paint

- Khimprom-M.

- Spectrum.

The price, depending on the manufacturer, is 100–150 rubles / kg. In addition to these properties, enamel protects surfaces from atmospheric changes, mechanical damage.

to contents ↑Technical specifications

Main technical specifications:

- coating - smooth, smooth, glossy, without pockmarks, wrinkles, pits;

- color - as indicated in the instructions, the exact depth of the shade is not regulated;

- viscosity on a VZ-4 viscometer at a temperature of +20 degrees - 30 s;

- solids content - 40–45%;

- drying time to the third degree at +20 degrees - 3 hours;

- milling degree - 80 microns;

- coating elasticity - 1 mm;

- adhesion to the base - 1 point;

- the flash point of the enamel base in a closed crucible is from –18 to –22 degrees;

- impact strength according to the device U-1 - 50 cm;

- resistance to chemicals at a temperature of +20 degrees: for gasoline - 24 hours, for technical oils - 24 hours, for a NaCl solution of 3% - 24 hours.

to contents ↑As a solvent, acetone, P-4 can be used, they are added no more than 1/10 of the total weight of the paint. After opening and dilution, the material is suitable for use for 8-12 hours at room temperature.

Application Technique

The tool is prepared as follows. The base is combined with a hardener - 0.02-0.025 hardener units are taken per unit of base. As the latter, AF-2 (at any temperature) or DTB-2 (only at temperatures above 0 degrees) is used. After the enamel must be thoroughly mixed and aged for 20-30 minutes, so that the hardener is evenly dispersed. If the normative viscosity is exceeded, solvents recommended by the instructions are added.

Metal surfaces must be well primed before painting. For this purpose, any soil can be used for metal, the layer thickness is less than 20 microns. Before priming, the surface is cleaned of rust and other contaminants by sandblasting. If there is a strong old coating, it can not be removed (it is permissible to leave coatings on an epoxy, vinyl base).

The material should be applied with a brush, airless spray. The rules for using enamel are as follows:

- temperature during work from –15 to +35 degrees, humidity - less than 80%;

- the drying time of the first layer is 3 hours, then the subsequent layers are performed;

- use the same solvents to clean the tools.

The consumption of paint per layer is 250 g / sq. m for airless spraying, 220–250 g / sq. m to use a brush.

to contents ↑Safety and storage

The material is flammable, toxic, due to solvents. Do not work with it near sources of heat and fire. Staining is carried out under condition of good ventilation or with sufficient purge in open areas. Workers must use personal protective equipment — respirators or gas masks, gloves, and durable clothing. If enamel gets on your skin, it is washed with soap with a large volume of water.

Material should be stored without access to the sun, moisture, away from heat sources. Storage is carried out in a special room, the shelf life is 1 year from the date of issue. The standard storage temperature is from –40 to +30 degrees. At temperatures below –25 degrees XC-436 can withstand no more than a month.