Aligning the walls is an obligatory stage of finishing work, without which it is impossible to give the base smoothness and prepare it for the finish facing. Often, cement-lime plaster is used for repairs at this stage - a durable, easy to apply and inexpensive material that is trusted by professionals.

- Where is cement-lime plaster used?

- Variety of formulations

- Lime plaster

- Lime-gypsum plaster

- Lime and clay plaster

- Lime-cement plaster

- Additional additives

- Advantages and disadvantages of the mixture

- Necessary tools

- Proportions of cement-lime mortar for plaster

- Cement-lime mortar preparation

- Surface preparation for processing

- Installation of plaster beacons

- Rules for applying lime formulations

- First step

- Second step

- Third step

- Ready plaster mix prices

Where is cement-lime plaster used?

Mortar based on cement and lime can be called a universal material for starting finishing. It is well suited for outdoor and indoor use, it is used in residential and industrial premises, warehouses, garages and outbuildings. This type of plaster can be used in the repair of facades of buildings, balconies and loggias, and with the introduction of special water-repellent additives, even for facing bathrooms.

Without enhancing moisture resistance, cement-lime mortar for wall plastering is not recommended in basements or other damp rooms.

to contents ↑According to SNiP, lime plaster in its pure form or mixed with gypsum is not suitable for places where air humidity exceeds 65%.

Variety of formulations

As binders, not only lime and cement can be added to the composition of plasters, but also clay, gypsum, and a number of artificial additives. The specific material used determines the properties of the solution, its strength, ductility and other technical characteristics. In most formulations, sand is also added, which prevents the plaster from cracking after drying.

Lime plaster

Lime plaster is widely used for leveling walls and ceilings in rooms with low and normal humidity. It is ideal for finishing masonry, which absorbs water well: the solution on the bricks dries quickly. When applied to wooden surfaces, on the contrary, inconveniences arise: the work is rather complicated, the mass lays down poorly and dries for a long time.

Without the introduction of additional substances, lime plaster has a low strength. You can store the finished mixture for up to three days, but its plasticity is gradually reduced. When applied, lime and sand based plasters are grayish in color, but after drying they turn white, therefore suitable for wallpaper or painting.

to contents ↑Lime-gypsum plaster

Such a building mixture is suitable only for internal work when applied to stone, wood, fiberboard, brick and cement substrates. It is important that the rooms have normal humidity: gypsum strongly absorbs water, and the composition based on it will not last long if it is not dry.

Subject to the specified conditions, the plaster has the following properties:

- high strength;

- quick drying;

- elasticity.

Gypsum seriously reduces the drying time of the mixture, so you need to breed it in small portions, and work as quickly as possible. Gypsum is added in small volumes to the finished plaster, which is then used for 10-15 minutes.

If the solution has become too thick, it is better to discard it and start a new batch, since the elasticity of the mass drops dramatically, and the finished coating will quickly crack. The introduction of water into the mixture that has already begun to set is erroneous, since the plaster will lose its strength.

to contents ↑Lime and clay plaster

Clay-lime mortar is used mainly in dry rooms. It is well suited for leveling brick, stone, wooden walls. Usually it is used in private homes, in summer cottages, in the decoration of farm buildings and industrial buildings. The advantages are environmental friendliness and low price of the solution, as well as the ease of working with it.

Lime plasters with added clay do not differ in high strength, therefore it is recommended to introduce sand, cement, gypsum in them to increase the durability of the finished coating. Complex kneading of the solution also becomes a disadvantage, because clay requires preliminary soaking for a day or more.

After soaking, the mass must be thoroughly kneading, adding water until a creamy consistency is obtained, wiping through a sieve so that there are no lumps, plant residues, solid inclusions. After sand and lime should be introduced into the clay, which increase the strength and plasticity of the solution. If you add a sufficient amount of cement to such a plaster, it will be moisture resistant and suitable for outdoor use.

to contents ↑Lime-cement plaster

This material is the most durable and is considered universal. It can be used for facade decoration, cladding socle, walls in rooms with high humidity. The composition sets in within 1-2 hours, so even a beginner can work with it.

Thanks to lime, it has increased elasticity in comparison with the usual cement-sand mixture, has excellent adhesion, reliably sets to the base. The coating will be resistant to various kinds of damage, it is easy to apply the material, it is suitable for any substrates, including concrete walls or masonry.

to contents ↑Additional additives

In any of these solutions, you can add other components that change the operating parameters for the better:

- quartz sand - increases decorativeness, resistance to chemicals;

- marble chips - enhances strength, makes the coating elegant in appearance;

- metal dust, shavings - increases impact resistance;

- mica - reflects ultraviolet radiation;

- polystyrene granules - provide thermal insulation properties.

to contents ↑

Advantages and disadvantages of the mixture

The advantages of cement-lime plaster are obvious:

- Graspability. The material is excellent for construction and repair, as it lies exactly on most of the applied substrates and is characterized by a high degree of adhesion with them.

- Plasticity and elasticity. Thanks to these properties, the plaster is easy to apply, quickly leveled, and after hardening does not crack, withstands shrinkage of buildings and structures.

- Vapor permeability. The ability of the plaster to “breathe” allows it to maintain a normal microclimate in the room, to exclude the accumulation of moisture and the multiplication of fungus, mold.

- Cost. Most brands of ready-mixed building mixtures have a low price. If you make the solution yourself, you can save even more.

Disadvantages of cement-lime plaster are also available. After completing work and drying, you can notice that the coating has acquired minor irregularities. To prevent this from happening, you should make the cladding multilayer, and wait until the previous layer has dried and only then apply the next.Usually 1-2 hours are enough, but with high humidity in the room this period can be up to 24 hours.

to contents ↑Lime-based plasters, especially with a small proportion of cement, may not seem hard enough. It must be remembered that the strength of the coating increases over time, and wait for the set interval before driving in nails or other mechanical operations.

Necessary tools

To work with plaster, you will need a bucket or other container, a drill with a mixer, a trowel, a spatula, a spatula or a trowel, a grater. With self-preparation of the composition, it is better to prepare a sieve to exclude the ingress of foreign impurities into the solution.

Proportions of cement-lime mortar for plaster

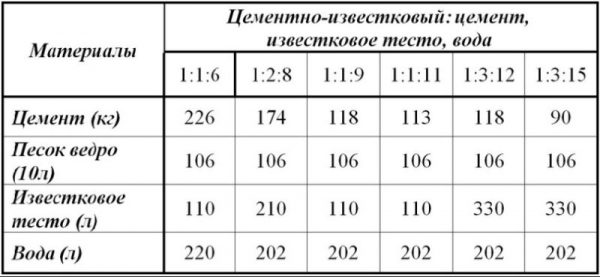

So that the result of the plastering works does not cause complaints, it is necessary to use high-quality components. It is better to purchase cement for the brand M-400, which does not have lumps, is friable. As for the proportions, 0.2-0.4 parts of lime and 3-4 parts of sand are usually taken for 1 part of cement.

The exact number of components depends on the required density, strength and ductility (indicators are regulated by the norm of sand, cement and lime, respectively). Another option for preparing the plaster is to mix 1 part cement, 1 part lime milk and 6 parts sand.

to contents ↑Cement-lime mortar preparation

After combining the dry components in the right proportions, the composition is diluted. For this, water is poured into a clean container, a powder mixture is gradually introduced (approximately 4.75-5.25 liters of water per 25 kg of mass). Mix the product with a construction mixer or drill with a special nozzle. After obtaining a homogeneous mass, it is left for 5 minutes to infuse, then knead again.

to contents ↑Surface preparation for processing

Before applying the plaster to the wall, you need to carefully prepare it. The process involves removing the old decorative coating. Also be sure to tap the existing layer of rough plaster to immediately remove the falling pieces.

If the plaster is peeling off, it will have to be completely cleaned off. After they clean the base from dust and contaminants, they are primed with a deep penetration composition. When it is required to strengthen the wall, a special metal or fiberglass mesh is applied (for example, in old houses or on supporting structures).

to contents ↑Installation of plaster beacons

Plaster beacons are needed to simplify the process of leveling walls. These are perforated strips of various thicknesses made of metal, which are easily installed on walls. Installation begins from the edge of the wall (approximately 30 cm from the corner). Using a level, draw a vertical line, apply several portions of the mixture along it and put the first beacon.

Similarly act on the other end of the wall. Top and bottom into the lighthouses are twisted by a self-tapping screw, nylon threads are pulled between them. Under them, the remaining lighthouses are landed on the solution every 1-1.5 meters.

to contents ↑Rules for applying lime formulations

In order to qualitatively perform plastering work, you must follow the sequence of actions at each stage.

First step

The first layer of plaster is called a spray. It is needed to maximize the filling of all pores, pre-treat the base and improve the adhesion of the plaster to the wall. The solution should not be too thick. It is thrown on the wall surface with a trowel, rubbed carelessly so that the layer thickness is 3-4 mm.

to contents ↑Second step

The second layer is called soil, it is the main one and has a thickness of up to 5 cm, but not less than 1.5 cm. The plaster for it is quite thick. It is applied after the first layer has dried with a trowel or a trowel, and the excess is removed with a metal spatula.After the layer is leveled, but leave it a little rough. In parallel, check the flatness using a level or plumb line.

to contents ↑Third step

The third layer is needed to eliminate small chips and other defects and the final leveling of the surface. The consistency of the mixture should be as if sprayed. The mass is applied to a slightly moistened base, the thickness of the layer is 2-3 mm. After the surface is rubbed with a construction grater.

to contents ↑Ready plaster mix prices

The cost of plasters based on cement and lime is from 6 rubles per kilogram, or from 150 rubles per package of 25 kg. Gypsum compounds are more expensive (from 230 rubles / 25 kg), reinforced moisture-resistant products - from 270 rubles / 25 kg.

Cement-lime mixtures are the most suitable option for leveling facades, interior walls and other surfaces. They are durable, reliable and inexpensive, because they are appreciated by finishers and builders.