Mosaic plaster is one of many finishing materials that differs from others in its interesting appearance. The composition includes stone chips, so after drying, the plaster acquires a special grainy texture. Such a coating for walls and columns was in demand even in ancient Greece, it is no less popular now.

- Features and scope

- Advantages and disadvantages

- Types of mosaic plaster

- Diameter

- Material

- Necessary tools

- Surface preparation

- Technology and application conditions on plinths and facades

- Environmental conditions

- Rules for applying plaster

- The use of plaster indoors

- Drying and Finishing

- Mixture consumption and damage restoration

- Material cost

Features and scope

Decorative mosaic plaster is a building mixture based on acrylic resin or other cementitious base with the addition of natural stone chips. A variety of rocks (marble, granite and others) act as a filler. In addition to crumbs, glazing pigments are introduced into the composition, giving the desired shade to the plaster. Also, the material may include additional materials: lime, gypsum, silicates, silicone, latex, cement - which help it gain the necessary performance properties.

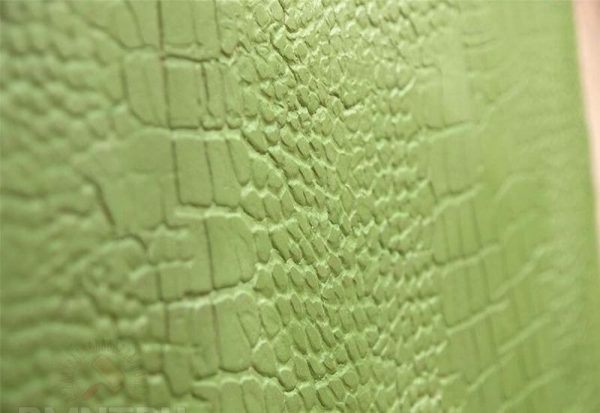

Mosaic plaster may include one or more types of rocks, and after hardening turn into a coating with a relief surface and interspersed with colorful pebbles, transparent glass.

Most often, for its production, different sizes of round-shaped elements without sharp edges are used, which eliminates unpleasant sensations during tactile contact.

This type of plaster is well suited for the facade, basement and other types of exterior structures, as well as for facing internal walls, columns, frescoes, niches and other parts of the interior. Since the material is not afraid of ultraviolet light, they can be used to decorate multi-story buildings and office buildings: it will retain the brightness of colors for many years.

to contents ↑

Advantages and disadvantages

Stucco based on natural stone has a lot of advantages:

- resistance to temperature changes, moisture, precipitation, wind, chemicals;

- the ability to wash the coating, including water under pressure and solutions with detergents;

- vapor permeability, the absence of harmful effects on the microclimate in the house, the exclusion of moisture accumulation under the coating and the multiplication of fungus, mold;

- long service life while maintaining an attractive appearance;

- universality: suitability for surfaces of stone, brick, cement, concrete, gypsum plaster, starting plaster;

- a large assortment of fractions, color schemes, basis, the ability to create a unique interior, matching different styles;

- concealment of base defects: cracks, bumps, other defects;

- high plasticity and elasticity, the ability to withstand shrinkage and even small earthquakes without damage;

- resistance to mechanical stress, the absence of scratches and chips even with long-term use;

- ease of installation, the ability to create conventional finishes and various artistic elements;

- seamlessness, formation of monolithic smooth surface without joints.

The cost of the material is quite high, this is its main drawback. Resin-based mosaic plaster is not applied to walls insulated with mineral or glass wool - you will have to choose a different finishing material or change the insulation. Dismantling the coating is difficult, so if you want to radically change the interior you have to work hard.

to contents ↑Types of mosaic plaster

Depending on the application, the plaster is divided into groups:

- for external works (front);

- for internal works (decorative);

- universal.

In addition, the material is classified by the size of the particles included in its composition, as well as by the type of base and filler.

to contents ↑

Diameter

According to the diameter of the stone chips, mosaic plasters can be:

- coarse-grained (1.5–3 mm);

- medium fractional (1.2–1.5 mm);

- fine-grained (0.9–1.2 mm);

- fine textured (less than 0.9 mm).

Material

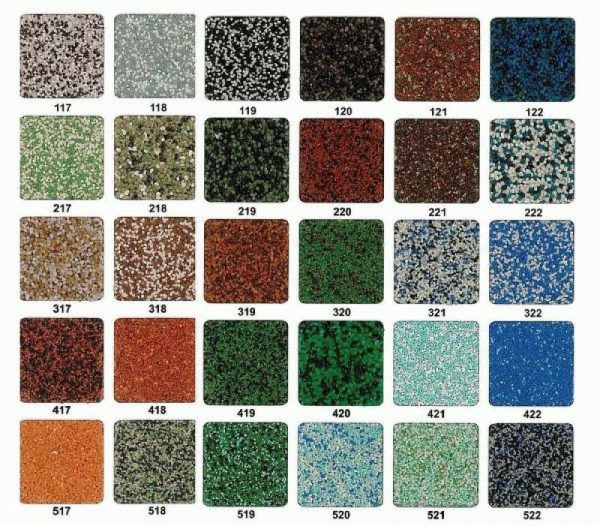

In the manufacture of mosaic plaster, various types of rocks can be used. Each determines the appearance of the material, its physical properties and technical characteristics. The most popular are plasters based on marble, quartz, granite, malachite, lapis lazuli, onyx, so on the packaging you can see the mark "marble", "quartz", etc. On sale there are mixed materials containing several types of rocks at once.

Plasters also vary depending on the binder, divided into the following types:

- Acrylic The composition contains polymer acrylic resins, due to the presence of which the material acquires plasticity, resistance to shock. Such plasters are easy to apply, inexpensive, and therefore very popular among finishers.

- Mineral Based on lime, cement, gypsum. For exterior work, mainly cement plasters with the addition of a small amount of lime are used, for interior use - gypsum. All mineral mixtures are characterized by vapor permeability, high strength at low cost.

- Silicate. They contain potassium glass, perfectly cling to the base, quickly harden, take any form. They have increased strength and wear resistance. The price of such plasters is an order of magnitude higher than that of mineral and acrylic.

- Silicone The composition of these plasters contains artificial rubber (silicone resin). They are usually used for interior decoration due to the average resistance to mechanical damage. The products form a strong elastic coating that is easy to clean and completely not afraid of moisture.

Necessary tools

To perform plastering work, you should purchase the basic material in an amount corresponding to the dimensions of the room, as well as tools and consumables:

- grater and grater;

- trowel and spatulas of different sizes;

- textured rollers, dies, stencils;

- masking tape;

- base plaster;

- primer and brush;

- polyethylene.

Surface preparation

Mosaic plaster is able to smooth out small defects of the base, but in general it should be as level as possible and not have large differences. The old coating is removed, cracks and pits are sealed with starting plaster. It is better if the latter has a white or other very light color, otherwise a rough coating can change the shade of the main finish. Check the evenness of the wall using a level or plumb vertically, horizontally, diagonally.

After leveling, a priming is performed, the purpose of which is to increase the adhesion of the plaster with the base and a more dense laying of the mixture. The primer is applied in 2-3 layers with an interval of a couple of hours so that it has time to dry out. Brush randomly, forming a light ribbed relief. You can use a sand (quartz) primer with a shade close to the color of the plaster.

to contents ↑Technology and application conditions on plinths and facades

External work requires careful observance of the sequence of actions and taking into account the recommendations of specialists.

Environmental conditions

Late spring is best for plastering if the weather is dry. The maximum permissible moisture content is 60%.You can not plaster facades, plinths in rain, snow, wet and cold weather, as well as in extreme heat. Ideally, if the temperature outside is 22-25 degrees.

Rules for applying plaster

First, the finished plaster mix is mixed well. If the composition is sold in dry form, dilute it with water, as indicated in the instructions, beat with a construction mixer or drill with the appropriate nozzle.

The solution is applied to the surface of the base or facade with a gusset using a spatula on a small area from corner to corner. Rub the mass with a trowel, holding the tool at a narrow angle, without strong pressure. They drive the trowel vertically or randomly, but not in circular motions, without rubbing (preferably from the bottom up).

The second layer is applied without waiting until the first is dry. They act in a similar way, forming a coating with a total thickness of 4–8 mm. After they take the grater, smooth the surface so that there are no voids between the grains, and the wall becomes smooth, smooth.

Strong pressure on the grater is not necessary, since this leads to the release of glue slurry and the appearance of strips from the edges of the tool. To form the corners, wait for drying, then carefully treat them with a grater. For drying, close the plaster with plastic wrap for 3-4 days, then remove the film.

The solution is applied to the metal in the following sequence:

- Any foci of corrosion are removed from the base.

- A special primer with anti-corrosion properties and a granular structure is applied.

- The plaster is applied in 2 thin layers (no more than 2-3 mm each).

If you plan to design a multi-colored facade, the borders of the joints of flowers are pre-sealed with masking tape. Mosaic plaster of a certain shade is applied with an overlap on the adhesive tape, immediately remove the protection after finishing work. Then a new strip of adhesive tape is glued to the already treated base, and the second shade is applied. As a result, the junction of the two colors will be smooth and beautiful. To create patterns on raw plaster, roll with stencil roller.

to contents ↑The use of plaster indoors

A material with a small fraction of the filler is well suited for interior decoration. Most often it is used for offices, private homes, balconies, corridors. No less relevant is the plaster for the kitchen in the area of the sink, apron. Looks great mosaic coating on corners, arches, in addition, it protects such places from damage.

Mosaic plaster is applied to well-aligned walls that have been thoroughly dried beforehand. A prerequisite is the priming of the base with quartz soil of a neutral shade. Usually indoors, only one layer of material is enough. Work is carried out with a spatula, trowel in the standard manner.

to contents ↑After application, the mixture is ground with a grater or rolled with a roller, sponge, rubbed with a trowel. To get an interesting decor, stick the stencil on the wall, fill the inside with plaster, level it and polish it. After complete drying, the stencil is removed.

Drying and Finishing

Drying should occur naturally, without the use of heating devices. Typically, the drying time of the material indoors does not exceed 48 hours. On the street, the process can drag on for 4 days. After curing, it is possible to cover the plastered base with varnish, wax, glazing composition. Such products enhance the radiance and provide additional protection against water, damage, dirt, dust and grease.

to contents ↑

Mixture consumption and damage restoration

The consumption rates of the material vary depending on the type of filler fraction. The approximate mass flow rate per square meter of surface will be as follows:

- fraction 0.5–1 mm - 2-3 kg;

- fraction 1–1.5 mm - 3-4 kg;

- fraction 1.5–2 mm - 4–5.5 kg;

- fraction of 2-3 mm - 5-7.5 kg.

to contents ↑Damage to the material occurs quite rarely due to its high strength. If this happened, you need to carefully remove the problem area, treat the chipped place with a primer and apply the same color plaster, carefully rubbing the joints.

Material cost

Estimated price of the material is 120–150 rubles / kg. It can increase when included in the composition of expensive components, for example, natural marble chips or silicate composites. The cost of finishing a square meter of the wall varies from 250 to 900 rubles or more.

Mosaic plaster has a number of features and has unique characteristics. It must be applied and dried correctly, and in this case the finished coating will be durable, pleasant to the touch and incredibly beautiful.