Cracks often appear on newly completed buildings or an updated stucco layer. The cause is uneven shrinkage or groundwater exposure, as well as a number of other factors. To avoid such problems, you need to consider the progress made. Elastic plaster is a novelty in the construction market, which helps to maintain an attractive finish and to avoid repeated repairs.

- Description of material and history of occurrence

- Advantages and disadvantages of plaster

- Specifications

- Where elastic plaster is used

- Types of elastic plasters

- Application of the composition

- Necessary materials and tools

- Surface preparation and priming

- Surface reinforcement

- Application of facade plaster

- Leading manufacturers

- Operation and maintenance

- Composition storage

Description of material and history of occurrence

Elastic plaster is often called rubber. Of course, there are no traditional rubber components in its composition, but the properties really resemble this flexible, plastic material that can bend without damaging the surface. Like rubber, elastic plaster is able to elongate when stretched by 15% or more, is not covered by cracks during movement, displacement, vibration of the base.

Today, flexible plaster is in the range of products of most well-known manufacturers of building mixtures. In relation to facade work, the material competes with classic mineral plasters, which even with small shrinkage of the building begin to deteriorate. Due to the low elasticity and elasticity, mineral mixtures cannot withstand difficult operating conditions and quickly cease to give the necessary protection to structures.

The main component of flexible plaster is acrylic resin - a substance invented in the mid-20th century. Like other artificial resins, it is characterized by flexibility after hardening, which is why it is now widely used for the manufacture of a variety of building materials: plasters, paints, stone. Initially, paints were created on the basis of acrylic, water and pigments, into which mineral filler was then added (up to 70% of the total mass). The filler may be:

- natural and synthetic fibers;

- stone crumb;

- quartz sand.

to contents ↑To improve the technical characteristics of the mixture, various modifying additives and plasticizers were introduced into it. Some hardening plasters contain a certain amount of cement, which in combination with acrylic makes the coating incredibly resistant to mechanical stress.

Advantages and disadvantages of plaster

The plaster is available in finished form, does not require mixing components. After application and drying, it forms a seamless coating resistant to weather conditions. The advantages of an elastic mixture are as follows:

- available in various shades and in white version, can be tinted in any color, painted after drying;

- easily lays down, does not require special knowledge for plastering, dries quickly;

- can serve as decorative plaster, if necessary, is subjected to embossed processing;

- environmentally friendly, does not emit harmful substances even when heated, does not emit an unpleasant odor;

- possesses high adhesion with most building materials (concrete, wood, brick, any porous substrates), does not lag behind walls;

- can be applied even to a layer of insulation, for example, foam, as well as other types of plaster;

- universal, suitable for facade work, decoration of internal walls and partitions, cladding of new buildings and restoration of old buildings;

- not afraid of exposure to the sun, water, not destroyed by the expansion of ice, can be used in damp rooms;

- permeable to water vapor and gases, does not change the conditions of the optimal microclimate in the room;

- maintains temperature differences within –50 ... + 60 degrees, does not spoil from freezing and thawing;

- It is considered non-combustible, provides fire safety of structures;

- the color does not fade, does not fade over time;

- prevents the appearance of mold, mosses, lichens;

- It serves several decades without loss of operational characteristics;

- it is easily cleaned of dust and dirt, washed with ordinary water.

to contents ↑There are few disadvantages of elastic plaster. This material cannot be called cheap - its cost is quite high, and a full finish of the building can cost a decent amount. In addition, it is not suitable for roughing with a thick layer, but is intended only for finishing or decorative finishing. Elastic plaster does not like seams, joints, therefore it is advisable to produce cladding on each surface in one go.

Specifications

“Rubber” plaster may have different technical characteristics, which vary depending on the manufacturer. The average parameters of materials of this type are as follows:

- consumption - 0.5–2.7 kg / sq. m (depending on the type, evenness of the base);

- drying time before treatment - 12-24 hours;

- time to set full strength - 14-30 days;

- water absorption rate - less than 1%;

- mass fraction of solids - from 70%;

- tinting - in any RAL colors;

- the possibility of dilution with water - up to 2%.

to contents ↑

Where elastic plaster is used

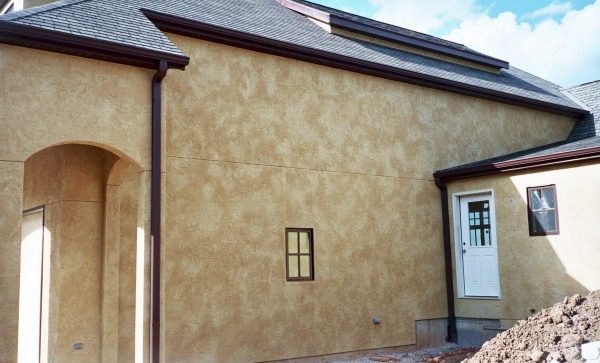

Most often, plaster is used as facade - it produces the finishing of the outer side of buildings, structures, structures. After drying, a kind of dense, but breathable membrane is formed on the surface, which does not pass water, protects the walls and does not become cracked during shrinkage and basement movements.

Plaster has a high rate of extensibility, so it can be used even on the most difficult sections of the facade. The material is ideal for new buildings, buildings located in seismically active zones. Elastic compounds are perfect for finishing decoration of insulated buildings as part of plaster systems.

The elastic mixture is suitable for wet rooms: bathroom, toilet, pool, basement, bath. The plaster layer can both stretch and shrink, so it can be used for facing corridors, halls, stairwells. Gypsum stucco is coated with plaster, products made of polyurethane, polystyrene, walls with many seams, joints are finished in order to obtain a seamless coating. If necessary, floor coverings are glued to the elastic plaster: parquet, carpet.

to contents ↑Types of elastic plasters

The material is available in two versions:

- Flexible acrylic plaster. This mixture is intended for finishing and protecting rooms, facades, other internal and external structures. It is made on the basis of acrylic resin, designed for work on concrete, brick, stone, galvanized steel, other metals, plates, plastic. The material is resistant to humidity and freezing temperatures.

- Elastic decorative plaster. In addition to protecting surfaces, the product has another purpose: giving an aesthetically attractive look.The decorating effect is achieved by incorporating a filler with a different shape and size of grains, as well as by applying special techniques for processing the plaster layer.

to contents ↑Most often, decorative plasters include structural polymer fibers, and somewhat less often, natural stone chips. With the help of such mixtures, various effects can be provided to the surface: imitation of gypsum, “fur coat”, “fleece”, “bark beetle” and others. Tinted decorative plasters work using sgraffito technique.

Application of the composition

For high-quality application of elastic plaster, it is necessary to monitor the fulfillment of a number of conditions. Work with such compounds can be carried out at a temperature of + 5 ... + 30 degrees, their use at negative temperatures is unacceptable. If plaster is applied to the facade, it is important that the wall is closed from wind, draft, precipitation, direct sunlight.

Humidity during surface cladding should not exceed 80% for outdoor use, 65% for indoor use. The material is used only in the design of vertical surfaces, in which the vertical deviation does not exceed 20-25 degrees. Elastic plasters must not be mixed with other building compounds, putty, paint.

to contents ↑Necessary materials and tools

Typically, plaster is applied to the walls with a wide metal spatula or trowel. Also, a plastic or polyurethane grater is useful for rubbing it. To give the surface a relief, use special graters, figured rollers and even improvised means. To paint the dried layer, you need paint, painting tools, for mixing the solution - a bucket, a construction mixer. You will also need a primer, reinforcing canvas, adhesive, dowels, antiseptic, rough plaster mix.

to contents ↑Surface preparation and priming

Elastic plaster has a high degree of adhesion with different surfaces, but without their careful preparation this figure can be reduced. Thanks to preparatory measures, the reliability, durability, durability of the finished coating is increased, the application of plaster is facilitated. Also, preparation helps to reveal defects, which are then eliminated.

First, dirt, protruding masonry mortar, other contaminants, and peeling old coating are removed from the surface. Be sure to clean off the enamel and oil paints, cracked putty and plaster. Chalk, lime are washed off with water, the affected areas are cleaned and treated with an antiseptic. Cracks are embroidered, carefully covered with cement mortar. Oil stains are removed with a solvent.

During the preparation, metal parts are covered with special insulating means, and fastening elements, screws are immersed in the wall by 1-2 mm. After drying, the base is treated with a primer, which is especially important with its high porosity. Otherwise, the base will draw water from the plaster, and the quality of the finished layer may decrease. The primer also helps to bind residual dust, strengthen the base and improve adhesion.

to contents ↑The primer is applied to 2 layers with complete intermediate drying. Then, if required, the substrates with sharp changes are plastered with mineral (polymer-cement) compositions along beacons, the joints are sealed with elastic sealants, and they are compared with the common surface. Only then the wall will be ready for finishing with elastic plaster.

Surface reinforcement

To strengthen the rough plaster layer on weak substrates, an alkali-resistant fiberglass mesh is used.It is attached to the wall with glue or dowels, regularly monitoring the position and eliminating sagging. Pieces of mesh are overlapped by 10-15 cm, well coated with glue. After the glue has dried, a leveling mortar is applied, then an elastic plaster.

Application of facade plaster

Acrylic plasters are perfectly applied and leveling, so you can work with them with a conventional spatula. Before coating the walls, the composition is thoroughly mixed, if necessary, a little water is added, but not more than 2% of the total volume. Start work from one wall, closing it completely, from one corner to another without interruptions. If the break in the work did happen, the edge of the dried area is abundantly moistened with water to a width of at least 30 cm, and only then continue to plastering. If you ignore this rule, an ugly transition will be visible on the coating.

Immediately after application and leveling, the plaster is rubbed with a grater again from corner to corner. If necessary, in the application of patterns carry out the necessary manipulations with the roller, stencils immediately after leveling the mixture. Then leave the plaster to dry for 12-24 hours, and only then do staining or varnishing.

to contents ↑

Leading manufacturers

In the construction market, various elastic compositions of domestic and imported brands are sold:

- I-Flex from Bayramiks. Finished decorative mixture with fine filler (0.7–1.2 mm). White, can be tinted, applied manually or mechanically, gaining full strength in 28 days. Coating is stretched by 15%.

- Ceresit CT-79. Elastic pebble composition in white with grain up to 1.5 mm, suitable for facades, plinths, garage entrances. Enriched with carbon and polyacrylamide fibers, fiberglass, silicone modifiers.

- Capa-Rollputz-Flex by Caparol. It is used in a wide temperature range, suitable for outdoor and indoor use. Contains grains of a fraction of 0.4–1.5 mm.

- Multiflex Nano and Nano lux from Polymer Megalopolis. Waterproofing acrylic compositions for universal use. They can be used as glue for reinforcing mesh, flooring, waterproofing. They have a high degree of adhesion with concrete (1.6 MPa), are applied by brush, roller, and are suitable for processing pool bowls.

Operation and maintenance

Until hardening, the plaster layer is protected from low temperatures and precipitation for at least a day. After drying, the elastic coating practically does not attract dust, therefore it does not get dirty. Too often, you don’t have to clean the surfaces, but if such a need arises, they are washed with water, a soapy solution, using a rag, sponge, soft brush.

Composition storage

The shelf life of the plaster is 1-2 years, depending on the specific brand. When freezing, it loses its properties, therefore it should be stored only at positive temperatures. It is advisable to place the package with the plaster in a dry, dark, cool place, excluding the penetration of direct sunlight. In the opened packaging, the plaster dries out rather quickly.

When decorating facades, it is important to consider the strength, durability, high quality and beauty of the material. Elastic acrylic plaster meets all these requirements, besides it can be applied with your own hands, which will save repair costs.