Plaster wall decoration is the most popular way to level surfaces. In addition to rough plaster, masters often use decorative, which not only evens out, but also gives the base aesthetics and an attractive look. A rather beautiful effect is created if plastering a fur coat is applied - an interesting material with which it is quite possible to work with your own hands.

- Fur coat plaster - what is it

- Plaster composition

- Mineral plaster

- Acrylic plaster

- Silicone plaster

- Scope of a fur coat

- Advantages and disadvantages

- Wall preparation

- Solution preparation

- Materials and Tools

- Plastering with various tools

- Manual styling

- Broom and stick

- Brush

- Grid

- Master OK

- Textured roller

- Mechanized application

- Manual sprayer

- Industrial compressor

- Coloring and tinting

- Popular manufacturers

- Knauf

- Lacra

- Elbrus

Fur coat plaster - what is it

Fur coat decorative plaster got its name due to its resemblance to fur products, in particular, sheepskin. The finished surface seems to be “fluffy”. This effect is achieved by introducing into the composition of the pebbles, other solid components of different fractions. After application to the wall, the material dries up with the formation of a rough layer, which resembles a slightly rolled up, crushed sheep’s wool.

to contents ↑Textured plaster coat is sold in every hardware store, this is a fairly popular product. It is sold in the form of a dry mixture for dilution with water, packaged in bags of 10-25 kg. Most brands produce gray and white plasters, although after drying any of them can be painted in the desired shade.

Plaster composition

Most often, sand-cement mixes are found in stores, although the composition does not have to include these components. Much better, but more expensive than acrylic or silicone resins.

Mineral plaster

Cement (plain or white) and sand are present as a base in mineral mixtures. Some plasters additionally contain lime. To optimize the properties of the material, polymer additives are introduced that increase moisture resistance, fire resistance, elasticity, frost resistance. In addition, the composition includes antifungal components that prevent mold from multiplying.

Mineral plaster coat is cheaper than other textured materials, because its components have a fairly low price. It is environmentally friendly, completely safe for humans, resistant to temperature extremes. Most mineral mixtures do not support combustion and are classified as fireproof. Their disadvantage is the tendency to crack, especially when subjected to mechanical stress, vibration, linear deformation. The rigidity of the plaster can be completely smoothed out by adding plasticizers, which give it increased ductility.

to contents ↑Acrylic plaster

Plaster coat based on acrylic resins is a modern synthetic material with high elasticity. Such a mixture after drying forms a durable layer, resistant to shocks and vibrations, therefore, it is ideal for regions where there are earthquakes and places located near airports and railways.

As a filler, the composition of acrylic plasters includes pebbles of different fractions. Small particles make the material suitable for internal work, larger ones make it possible to obtain significant embossment, therefore they are suitable for facade decoration.

Improving additives, for example, bactericides, fungicides, adhesion promoters or substances that increase resistance to ultraviolet rays, are also introduced into acrylic plasters. Acrylic materials are not used where open flame sources are located. Resins can ignite from intense heat, which is the main disadvantage of the material.

to contents ↑Silicone plaster

Silicone resin blends are more expensive than others. They are practically devoid of the disadvantages of acrylic and mineral compounds. Polymer resins give the solutions high strength, wear resistance, excellent elasticity and the ability to withstand any load. Among the shortcomings, in addition to the high price and high cost of large-scale repairs, it can be noted the long drying of the plaster layer, which is important to consider when working with it.

to contents ↑Scope of a fur coat

Like other textured plasters, a fur coat is ideal for facing facades and socles of buildings, structures, especially if the fraction of pebbles in it is large. The fur coat can be trimmed and the internal walls in houses and apartments, applied to columns, bas-reliefs. For this purpose, fine-grained material with a smoother texture is ideally suited. Plaster coat with any composition is suitable for work with all building bases:

- concrete;

- aerated concrete;

- brick;

- drywall, etc.

Advantages and disadvantages

Stucco with a fur coat effect has many advantages that determine its popularity:

- Ease. Despite the presence of pebble filler, the material is lightweight and does not burden building structures. Before performing a layer of plaster it is not necessary to strengthen the foundation.

- Profitability. Most mineral compounds have a low cost, so repairs will not result in a significant amount. To work manually you do not have to buy expensive tools, and you can apply the plaster yourself. Acrylic and silicone plasters are more expensive, so they are not always economical to use.

- Environmental friendliness. All compositions with the effect of a fur coat are environmentally friendly, do not harm a person, even when heated they do not emit toxic substances.

- Excellent technical properties. Materials of this type are not afraid of the rays of the sun, do not fade, do not deteriorate from water, temperature changes. They have a high degree of adhesion to all surfaces, immediately adhere to them and are not subject to destruction.

- Heat and sound insulation. After applying the plaster, the wall receives additional insulation, high-quality insulation from extraneous noise. The fur coat can be applied as an independent insulation (in a temperate climate) or in combination with other types of heat-insulating materials.

- Seamlessness. The finished coating will have no seams, joints, so cold bridges are not formed in it, moisture does not accumulate in defects.

- Vapor permeability. The material allows the walls to breathe, does not violate the indoor microclimate.

- Maintainability. If a separate area is damaged, the fur coat can be restored without problems. As a result, the appearance of the new site will be indistinguishable from the rest.

- Easy to apply and care. You can master the technology even without experience in finishing work. After drying, the plaster layer can be washed, as it does not deteriorate from water, and with the use of detergents.

Professionals highlight a number of shortcomings that are inherent in textured plaster. For example, cement compositions without additional processing do not have a long service life, although silicone mixtures last several decades without spoiling the appearance. Some designers consider the fur coat an obsolete type of finish and prefer to use more modern methods and materials.

Among the disadvantages is the quick contamination of the stucco structure - dust penetrates into the relief bends, so you will have to wash the walls more often. In comparison with specialized heaters, the fur coat loses, because the foam inside the foam gives additional thermal insulation properties to the foam and mineral wool. To get a decent level of insulation, you will have to apply a thick layer of plaster, which is not always possible.

to contents ↑Wall preparation

Prior to the start of surface finishing with stucco, proper foundation preparation is required. Initially, the walls are cleaned of dust, dirt, and grease stains are wiped off with a solvent. If there is an old falling off plaster, it is considered, as well as paint. Cracks, pits close up with ordinary cement mortar. As a result, the wall should become smooth so that the differences do not exceed the size of the plaster grain.

If the base, on the contrary, is too smooth, then the adhesive force with the solution may decrease. In this case, create artificial irregularities - they treat the surface with a chisel or make small notches with a grinder with a special nozzle. Then, to remove dust and increase adhesion, the wall is coated with a primer. Among other things, the soil will help strengthen the base and reduce the risk of mold and mildew propagation. The tool is applied with a roller or brush, and sprayed onto the surface with notches from the spray gun. Allow the primer to dry (at least 4 hours), then proceed to the main stage of work.

to contents ↑Solution preparation

Before use, dry building mix is diluted with water according to the instructions. It is enough to pour a measured portion of the composition into the water, mix it with a construction mixer, and the plaster will be ready. Acrylic and silicone compounds are usually sold ready-made in jars. Before applying them just need to be mixed with a wooden spatula.

to contents ↑If you decide to make the plaster yourself, connect 3 parts of sifted sand with 1 part of cement, fill the mass with water (200 ml of liquid per 1 kg of dry matter). The construction mixer beat the solution well, after 5 minutes repeat this operation and introduce a portion of the filler of the desired fraction.

Materials and Tools

Fur coat plastering can be applied in different ways, and depending on the particular method chosen, the list of accessories for work varies. In addition to the plaster itself, primer, container and mixer, it is necessary to prepare:

- a roller, brush, broom or net;

- building grater;

- sprinkler;

- compressor.

Plastering with various tools

The process of plastering surfaces with a fur coat is quite simple, it is important only to familiarize yourself with its sequence and nuances in advance.

Manual styling

Typically, non-professionals use hand tools in their work, which are inexpensive and allow you to get the desired texture without any special costs. Such devices are well suited for small areas.

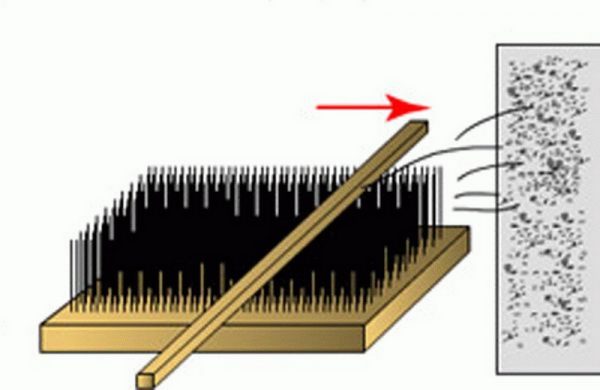

Broom and stick

For this method, you don’t need to buy tools at all, because it’s easy to get an ordinary broom and a simple wooden stick. A broom is required to spray the plaster on the wall. At first, the “tool” is dipped in a plaster mass, then it is dipped on a stick, holding the latter not far from the wall parallel to the ground level. When biting impacts under the action of centrifugal force, drops of plaster fly to the wall and firmly attach to it.

Work with a broom and a stick is quite long and laborious, therefore this method has long been considered obsolete and is rarely used. It will take a huge amount of operations of the same type to coat the entire wall with a fur coat.It is better to practice this technology if you plan to finish a small surface. In addition, the broom from manipulation quickly fails, and on the base there may be places where the plaster will fall in an insufficiently thick layer.

to contents ↑Brush

This method also does not belong to the category of modern ones. It does not make it possible to apply a thick plaster layer, but is used only to make thin coatings that do not serve as noise and heat insulation. To work, you need a stiff brush and a small wooden board. The sequence of actions is as follows:

- flat rectangular brush dipped in plaster;

- turn the tool with its bristles up, placing it horizontally;

- move the plank over the brush toward you;

- the hairs of the brush bend, then straighten and “shoot” with plaster directly on the wall, forming the desired relief.

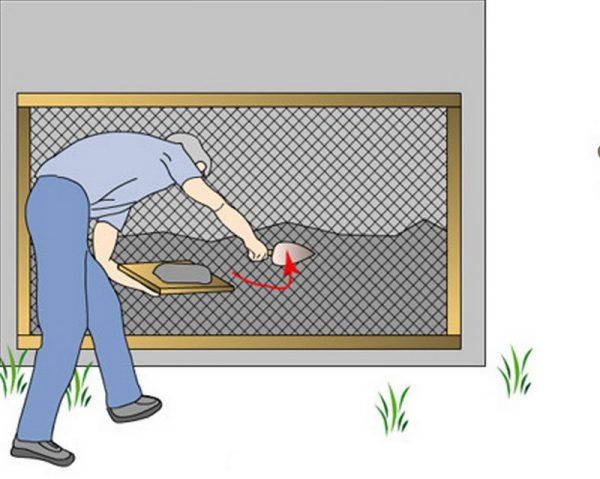

Grid

With the help of a fine mesh netting, you can also create an invoice on the wall. The grid is fixed at a small distance from the surface, then with the help of a trowel, a solution is sprayed so that its portions fly through the cells. The plaster breaks on the fly and forms a unique pattern. After completion of the work, the grid is removed.

Master OK

A construction grater (trowel) will also serve as a tool for applying a fur coat. In addition, a spatula with which the plaster is applied to the trowel is required for work. Next, they press the trowel against the wall so that it imprints in the solution, and abruptly tear it off. A rough textured surface is formed, which is then slightly smoothed with a grater moistened with water.

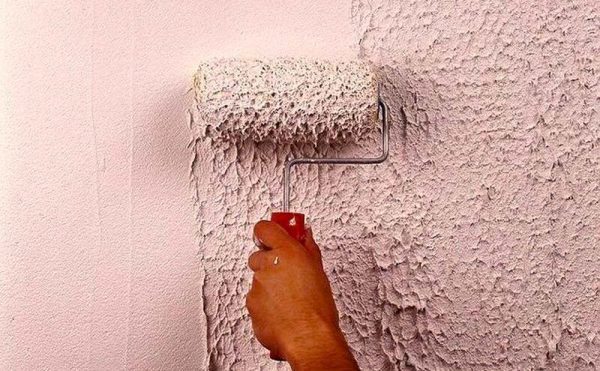

to contents ↑Textured roller

Using the roller, you can quickly and easily achieve the desired relief on the plastered wall. Even large areas are treated with a roller in a short time. First, the plaster is applied to the base with a spatula, gently distribute it and align with the rule. Then rolled with a textured roller over the entire treated area, resulting in a beautiful pattern. If work is carried out with the internal surfaces of the building, as the surface dries, the relief is slightly leveled with thin sandpaper.

Mechanized application

Professional finishers use special equipment to cope with the plastering work faster and without unnecessary labor.

Manual sprayer

Hand-operated plastering machine is a popular fixture, which greatly simplifies the task of the master. The capacity of the machine is filled with the ready-made solution, after which they begin to rotate the handle. The latter engages the shaft, which is located under the tank. Metal tendrils attached to the shaft “shoot” with stucco particles directly on the wall. The size of the drops is adjusted by adding water. The result of the work will be more uniform, high-quality than when applying the mass with the above devices. Manual sprayer can be used for applying plaster both outdoors and indoors.

to contents ↑Industrial compressor

The method using the compressor is the most modern and effective, because plaster with its help is sprayed on the wall in a matter of minutes. For a minimum time period, you can process significant areas of walls or other surfaces. The finished coating will be smooth, smooth and very beautiful, its service life will increase.

Plaster is sprayed out of the hose under the influence of air flow, which is supplied under pressure. It is not difficult to operate the equipment, however, its price is quite high, so buying an industrial compressor for home use is not always advisable. Using equipment, you can change the texture of a fur coat. If you need to get a fine coating, make the plaster more liquid, prepare a thick solution for a large relief.

to contents ↑Coloring and tinting

Plaster coat requires staining, as it itself is white or grayish in color.You can paint the finish after it dries or add pigments to the composition at the kneading stage. Tinting gives a more reliable, aesthetic result, although it requires more thorough mixing of the mixture.

The easiest way is to add some paint to the plaster. Dry pigments such as powdered coal, manganese, red iron ore, cobalt glass are also suitable. After applying the plaster, it will not have to be painted, and the pigment color will remain for a long time. There are few disadvantages of this technique. You will have to carefully measure the amount of dye, because otherwise, different portions will look different.

Painting an already dried surface is rather laborious, because its texture is rough, with bulges and pits, therefore it is poorly stained. It is best to carry out all the manipulations with the help of a spray gun, in extreme cases, use a fleecy roller. Painting with a brush is not a very rational solution, which will require a lot of time and effort. The technique has other disadvantages:

- only the surface layer of the plaster is painted, so the durability of the coating is reduced;

- if cracks appear on the plaster layer, they will be ugly in the eye, and the lack of paint inside will only emphasize the defect;

- if the plaster is gray, it is problematic to paint it in light shades, only painting in bright, saturated colors is possible.

Popular manufacturers

Most modern manufacturers produce coatings with the effect of a fur coat. Below are examples of the most popular plaster mixes with this texture.

Knauf

For plastering like a fur coat, the Knauf line has a high-quality mineral mixture - Diamant. It is implemented in 25 kg packages and has a lot of advantages:

- suitable for exterior and interior decoration;

- includes grain fractions up to 5 mm, so it gives an even, beautiful coating that is easy to paint;

- made in white, can be repainted many times;

- It is applied by any manual and automatic tools;

- has moisture repellent properties;

- resistant to vibration due to high elasticity;

- differs in economical consumption;

- easily tolerates environmental factors, is not afraid of mechanical damage;

- withstands up to 50 freezing and thawing cycles.

Lacra

Domestic Lacra plaster contains mineral components, water-based acrylic dispersion, as well as functional additives and titanium dioxide. Due to the last specified component, the mixture is characterized by increased whiteness, therefore it is easily tinted with any pigments and painted even with light colors.

Lacra has the ability to level the base, so it can even be applied to walls with a moderate amount of defects and drops without prior alignment. The finished coating is resistant to atmospheric factors, permeable to vapors, breathable, it does not violate the indoor microclimate. The composition is odorless, after drying it is not afraid of damage and can be washed.

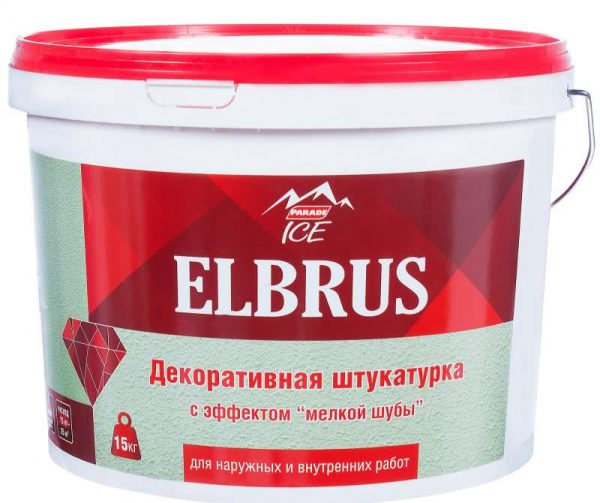

to contents ↑Elbrus

This decorative plaster is also produced in white and is ready for use, sold in buckets of 15 kg each. It is ideal for concrete, stone, brick foundations, and after drying it looks optically voluminous. The effect of a fur coat with such a mixture is easily achieved using a roller. "Elbrus" is characterized by low consumption, high strength and long service life.

Fur coat plastering is an excellent solution for interior walls and facades. Thanks to originality, it will be able to make housing unusual, memorable, moreover, it is very practical in everyday use.