In the construction and repair, completely different materials are used, and concrete is the most popular and sought-after of them. It has several varieties that differ from each other in characteristics and appearance.

- What is clear concrete?

- The history of transparent concrete

- Advantages and features of the release

- Properties of clear concrete

- Scope of transparent concrete

- Cost and brands

- Do it yourself

- Materials and equipment

- The composition and preparation of fine concrete

- Material forming

- Finishing

Unique and unusually beautiful is the latest generation material - transparent concrete, which can transmit light and make the interior stylish and attractive.

What is clear concrete?

Conventional blocks are made on the basis of cement, crushed stone, sand. They have a grayish color and a matte texture. Transparent concrete is capable of transmitting light, and its composition is slightly different:

- light or dark cement;

- fine sand;

- fiber optic fibers;

- special additives - modifiers, plasticizers.

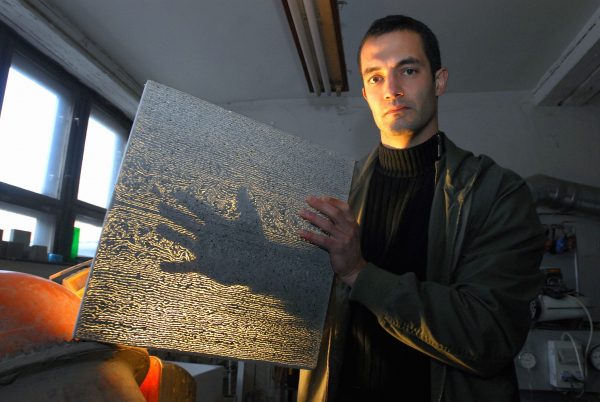

Coarse-grained aggregates or internal reinforcing agents are not used for the manufacture of transparent concrete - to obtain a durable material, the introduction of optical fibers with a diameter of 2 microns to 2.5 mm is sufficient. It is these fibers that give concrete aesthetic appeal without loss of density.

to contents ↑The history of transparent concrete

Light-conducting concrete was invented when trying to invent a more beautiful building and finishing material. Despite the fact that he came into fashion only in recent years, the development itself has been around for many years. Transparent concrete was invented in 1935 by the Canadian Bernard Long, but only in the 90s of the last century was patented under the name Litracon and gained improved technical parameters.

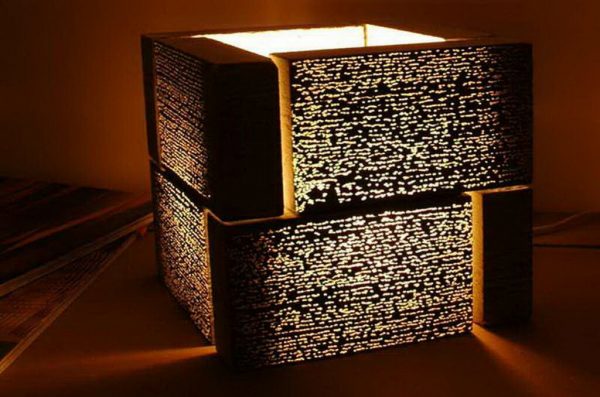

The creator of modern technology is the Hungarian architect Aron Loskonsi, who came up with the idea of introducing light-conducting fiber fibers into concrete. The first product of this material was a cube lamp weighing about 10 kg, after which the substance began to actively capture the market and displace analogues.

Advantages and features of the release

Clear concrete is an environmentally friendly material containing only safe components. All of them, including optical fibers, preliminarily undergo an environmental review for the content of harmful substances. Litracon is made in plates and blocks of different sizes, which allows you to easily select the right products for specific conditions of use.

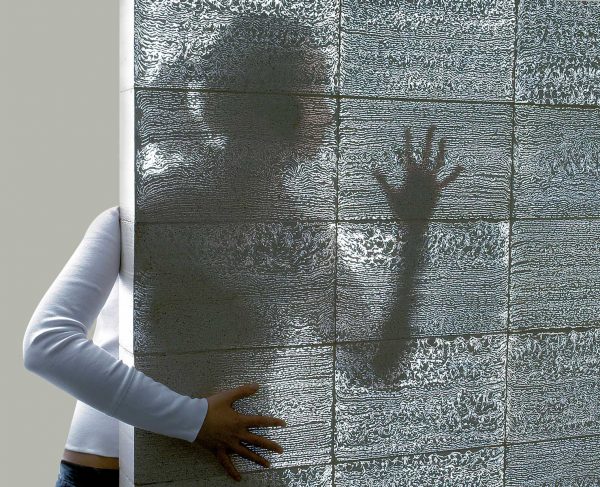

Concrete with fiber fibers is widely used in interior design and construction, although it is not suitable for creating monolithic structures, because it does not receive maximum strength. It is also impossible to do it in the formwork directly on the construction site, due to the complexity of production. You have to buy concrete in a ready-made form. For release technology of vibrocasting or pressing is applied. The solution is poured into the form layer by layer, alternating it with fiberglass.It is even possible to perform a certain light pattern, which gives uniqueness to the finished material.

to contents ↑Properties of clear concrete

Glowing concrete is a full-fledged composite material, which has good technical characteristics. Here are the main ones:

- bending strength - 2 MPa;

- compressive strength - 35 MPa;

- water resistance index - W4 – W8;

- frost resistance - 75 cycles;

- water absorption - less than 6%;

- average density - 2300 kg / cu. cm;

- thermal conductivity - 2.1 W / m / degree;

- sound insulation - up to 48-52 dB;

- combustibility class - NG.

Ultraviolet radiation does not adversely affect transparent concrete, but it is not resistant to silicate corrosion in a humid environment, and therefore requires treatment with protective agents for outdoor use. As such compositions, waxes for stone, silicate or lithium impregnations, and silicone-based solutions are used.

Transparent concrete is subject to grinding, cutting holes, polishing and other activities at the request of the user. The thickness of the plates usually does not exceed 20 cm, although even through two-meter blocks a light beam will pass. During the day, the plates let in sunlight, at night - rays of artificial light.

to contents ↑Scope of transparent concrete

The original material is very popular among designers and planners, both in the field of low-rise and industrial construction. Transparent blocks give a unique look to buildings, alternating with other materials. They are great for high-tech, modern buildings.

No less well the material fits into the interior of houses, apartments, suitable for finishing house buildings. From it you can do:

- stairs

- partitions;

- countertops;

- sinks;

- benches;

- fountains;

- wall niches;

- lighting;

- bar counters.

to contents ↑With transparent concrete, you can decorate the interior walls and floor, equip zone fences from it and even install plumbing, however, the price of each finished product will be considerable.

Cost and brands

Transparent concrete of foreign brands Litracon and Lucem is sold on the market, as well as one Russian - Lumikon. The first two companies do not produce material, but are distributors of European manufacturing plants, so the cost, taking into account delivery, will be very high, for example:

- prefabricated panel 120 x 40 x 2.5 cm - about 90 thousand rubles., 120 x 40 x 20 cm - up to 320 thousand rubles;

- a plate 125 x 65 x 5 cm - 85–90 thousand rubles;

- countertop - from 80 thousand rubles.

The Russian company performs a full cycle of production of transparent concrete directly in the Russian Federation, in addition, it specializes in individual production of products. The main colors of concrete are dark gray, gray, sandstone, white marble. The price per square meter, depending on the thickness of the plate, is 30–65 thousand rubles.

to contents ↑Do it yourself

Due to the very high cost of the material, many try to make it with their own hands. The process is simple, but it has important nuances that must be taken into account. The main difficulty is to comply with the laying vector of fiberglass material, because it must be located in a special way.

Materials and equipment

To work, you will need:

- construction mixer or concrete mixer;

- finished formwork;

- Portland cement M400;

- fine quartz sand;

- pure water;

- plasticizer;

- fiber optic threads.

to contents ↑The length of the threads should correspond to the thickness of future plates or blocks, and the diameter should be equal to 0.5–2.5 mm. It is impossible to ignore the introduction of plasticizers: they help the structure to become sufficiently dense, homogeneous.

The composition and preparation of fine concrete

For the manufacture of cement, cement is combined with sand in a ratio of 1: 3, adding water in the volume of half the mass of cement. For 1 cubic meter of concrete, 1300-1500 kg of sand, 450-500 kg of cement, 200-250 liters of water are needed. The dosage of the modifier should be consistent with the manufacturer's recommendation (usually 1–6%).

Mix the solution only in special equipment (mixer, concrete mixer) in small portions so that the mass is homogeneous. With manual kneading, it is almost impossible to achieve this effect. Ready concrete should be movable, but not too fluid with no signs of delamination. Mixing with most of the liquid lasts about a minute, then water is added to normal, after which the solution is mixed for another 5-8 minutes.

to contents ↑

Material forming

The formwork should have the form of a box and be equipped with sliding walls that can smoothly move upward as the lower layers of concrete solidify. Any formwork configuration can be done, but for beginners it is better to choose the simplest rectangular shape.

The block is poured with a mixture in several stages. The first layer is made thin (1 cm), the optical fiber is immediately distributed over it, slightly recessing it. The bundles should completely cover the surface of the solution, while you can draw any patterns with them, execute logos or just lay them horizontally / vertically. After setting, a new layer of concrete of the same thickness is carefully poured, compacted, an optical fiber grid is laid, placing it across. Repeat the work, moving the box until the desired dimensions of the product are achieved.

As the last layer solidifies, the formwork is removed. The finished concrete slab is allowed to finally dry at a humidity of up to 95%, a temperature of about +25 degrees. Under these conditions, the drying time will be 3-5 days.

Finishing

Upon reaching 80% strength, concrete can already be further processed. It is necessary for the material to obtain the necessary light conduction, because after stripping it remains covered with cement milk and does not transmit light. Grinding of all side faces is carried out with diamond disks with different grain sizes, after polishing the working surface to a mirror shine. Any products can be cut from the finished plate: tabletops, decor elements, lamps - it all depends on the capabilities and imagination of the master.