Aerated concrete is becoming increasingly popular in private buildings, in many cases displacing brick. It is much easier to work with it, and the houses are durable, warm and comfortable to use. The technical characteristics of the material are not quite ordinary, so the external and internal wall decoration will have a number of features. Aerated concrete plastering is the most common way of facing, which is carried out taking into account many nuances.

- Features of aerated concrete

- Plaster requirements for aerated concrete

- Types of plasters for aerated concrete

- Mineral plaster

- Silicate Plaster

- Silicone plaster

- Acrylic plaster

- Cement-sand plaster

- Lime-cement plaster

- Gypsum plaster

- Popular stucco manufacturers

- Stucco Tools

- Features of plastering

- How and with what to plaster aerated concrete inside the house

- Foundation preparation

- Priming

- Beacon Installation

- Throwing a "fur coat"

- First layer processing

- Forming angles

- Finish finish

- Plastering aerated concrete outside the house

- Surface preparation

- Padding

- Reinforcement and Alignment

- Finish finish

- Hydrophobization

- Optimal conditions for applying plaster

Features of aerated concrete

Aerated concrete is cellular concrete, throughout which small pores are evenly distributed. In the production of the material, cement, quartz sand and special blowing agents are used, as well as gypsum, lime. When a blowing agent (often aluminum) interacts with a cement or lime mortar, the latter foams with the formation of a porous structure.

Due to the presence of many internal cells, aerated concrete has good thermal insulation, no worse than wood. Its thermal conductivity is lower than that of a brick. Aerated concrete houses are being built very quickly, since it weighs a little, and the complexity of the work is reduced. In buildings made of aerated concrete creates a favorable microclimate. Among other advantages, it is worth noting the fire safety of the material, as well as the ability to do the laying with your own hands, without involving professionals.

Aerated concrete is insensitive to environmental factors. However, its bending strength and mechanical stability are not high, so cracks and chips appear over time. Aerated concrete blocks require mandatory finishing from the outside and from the inside, because:

- blown by air currents, which greatly reduces the amount of heat in the house;

- have an unaesthetic appearance;

- have high absorbency;

- susceptible to corrosion in winter;

- characterized by not too high soundproofing ability.

To improve the quality characteristics of the blocks, plastering with the use of special solutions is recommended. Plastering walls of aerated concrete will increase the durability of buildings, give a beautiful appearance and protect against destruction. If you do not use plaster, after a few years, the blocks will darken, begin to delaminate, so the facade finish is best done on time.

to contents ↑

Plaster requirements for aerated concrete

Since aerated concrete blocks have open pores, the finished structure from them is vapor-permeable.On the one hand, this is a plus, because condensate will not accumulate inside the house, mold will not develop. On the other hand, pores increase hygroscopicity, and absorbed moisture begins to destroy small cells. In connection with such properties, the main requirement for stucco for aerated concrete is its moisture resistance - the ability to reliably protect walls from moisture, but without violating vapor permeability.

According to SNiP, the vapor permeability of materials in heated buildings should increase from the inner layers of the walls to the outer. Only in such conditions will the supporting structures function normally. The vapor permeability of aerated concrete is 0.11-0.23 mg / m. h Pa, therefore, the plaster should be characterized by an indicator of 0.12 mg / m. h. Pa and more. Other requirements for stucco for aerated concrete are as follows:

- excellent adhesion to the base;

- frost resistance from 35 cycles and above;

- good compressive strength, elasticity;

- resistance to atmospheric factors;

- sufficient decorative properties.

Types of plasters for aerated concrete

Several types of plaster mixes are suitable for processing aerated concrete slabs, so the master always has a choice.

to contents ↑Mineral plaster

Most often, mineral compounds are used for plastering aerated concrete. There are special thin-layer plasters for aerated concrete on sale, in addition, many mixtures can be made independently. Advantages of mineral plasters are low price, low weight, high vapor permeability. Plasters are available in white or gray, but they can be painted or tinted.

Usually mineral compositions contain white cement, quartz sand, marble chips, lime. Various polymer components are introduced into the factory plasters to improve their properties. Home-made solutions are usually made from cement, lime paste and sand, or only from sand and lime. The latter option is not too successful, since the moisture resistance of the plaster will be low.

to contents ↑Silicate Plaster

The role of the binder component in such compositions is played by liquid potassium glass. It seriously increases the life of the plaster (up to 25 years) and optimizes its other technical parameters.

As a result, the solution will have such advantages:

- implementation in finished form;

- ease of application;

- resistance to moisture;

- high vapor permeability;

- the possibility of coloring and tinting;

- the presence of decorative properties;

- the possibility of application as a topcoat.

Silicone plaster

A plaster mix based on organosilicon polymers is considered ideal for finishing work with aerated concrete. Its operational and technical characteristics are at a high level. Plaster repels water, while it is vapor permeable, resistant to any atmospheric factors. It is easily applied, does not lose external attractiveness for a long time.

Silicone plaster is highly elastic, does not crack even from vibration and shrinkage of buildings. Silicone-based mixtures are sold ready-made in buckets, and there are already painted options on sale. Even in construction stores you can find decorative silicone mixtures with a variety of structural fillers. The downside is the high price of such materials.

to contents ↑Acrylic plaster

Acrylic compounds, like previous polymer plasters, have excellent decorative properties and considerable strength. However, for aerated concrete this is not the best option, because acrylic plasters have low vapor permeability. After application indoors, condensation will accumulate on the plaster layer. This will lead to a gradual detachment and cracking of the coating.

to contents ↑The conclusion is this: acrylic plasters can be used for work on aerated concrete only subject to the availability of internal waterproofing.It is also important to equip good ventilation, which eliminates the low vapor permeability of the material.

Cement-sand plaster

The usual cement-sand mixture without the introduction of additional additives is not very suitable for facing aerated concrete. Standard solutions are too dense and heavy for the blocks, and their adhesion to the surface is small. When applying plaster to aerated concrete, the latter begins to absorb moisture, which only reduces adhesion. As a result, the integrity of the finish is broken, cracks appear on the surface.

The vapor permeability of standard cement plasters is lower than that of mineral mixtures with various modifiers. Since this indicator is lower than that of concrete itself, the creation of a normal microclimate in the room will be impossible, which violates building codes. Modern manufacturers change the properties of cement mortars by introducing various synthetic additives.

to contents ↑Lime-cement plaster

The introduction of lime solves the problem of low plasticity of cement mortars, their ability to crack and poor adhesion to aerated concrete. The lime component helps to increase vapor permeability, and this indicator will be at a sufficient level, and the coating will not violate the natural microclimate in the room. The finished plaster is durable, flexible, environmentally friendly, and adheres firmly to the base. The price of lime-cement plasters is low, in addition, you can cook them yourself.

to contents ↑Gypsum plaster

Gypsum mortars are widely used for interior decoration of aerated concrete. They have many positive aspects:

- harden quickly and gain full strength;

- practically do not shrink;

- not susceptible to cracking after solidification;

- have a high level of vapor permeability;

- plastic, easy to apply on the base;

- keep their shape, do not flow;

- do not bear fire danger, are environmentally friendly;

- do not give moisture to porous substrates;

- lightweight, do not burden the structure;

- do not require the application of finishing putty;

- easy to repair, polished;

- give a very smooth finish.

It is impossible to use gypsum mortars for plastering facades or walls in wet rooms. They are very afraid of water, which is quickly absorbed and then destroyed. Gypsum does not tolerate frost, temperature changes and has a shorter service life than mineral and synthetic plasters.

Typically, gypsum mixtures are used to decorate interior walls and partitions with a flat surface to make the layer as thin as possible. When perlite is added, gypsum plaster can be used to insulate aerated concrete walls from the inside of the room.

to contents ↑Popular stucco manufacturers

If you decide to use factory building mixes for plastering aerated concrete blocks, you should pay attention to reliable, proven brands:

- Ceresit CT 24. Mineral composition with high ductility. Easy to apply, can be applied with a layer of 3-30 mm, withstands temperature extremes within –50 ... + 70 degrees. The plaster tolerates up to 100 freezing and thawing cycles, can be painted 7 days after application.

- "Founces Startwell T-21." Cement and lime based plaster. It is not subject to shrinkage, does not deteriorate from water, has a high degree of adhesion with aerated concrete blocks. It does not freeze for a long time, which makes it possible to work with a new portion up to 3 hours. The temperature range of operation of the plaster is –50 ... + 65 degrees, frost resistance - 50 cycles.

- Ceresit CT 77. Composition based on acrylic with the addition of mineral components. It is used for external cladding of aerated concrete subject to good ventilation of the premises and the presence of internal waterproofing. Plaster allows you to make a thin, durable coating that does not respond to environmental factors, tolerates up to 100 freezing and thawing cycles.

- Baumit SilikonTop.Highly flexible silicone compound that adheres firmly to the aerated concrete base. It gives an elastic protective layer that does not deteriorate even from regular contact with water and repels dirt. Available in white and color shades (about 200 options).

- Weber Pas S Another silicone plaster for indoor and outdoor use with a decorative effect (fur coat and bark beetle). It does not deteriorate from moisture, ultraviolet radiation, temperature changes. It is tinted in 218 flowers. It allows you to create a reliable thin-layer coating, ideal for aerated concrete and facade insulation systems.

- Baumit SilikatTop. Silicate plaster for facade applications. It is available in various forms in terms of grain size (1.5-3 mm) and color (200 species). Allows you to get a durable coating with a high degree of vapor permeability and moisture resistance.

- Baumit MPA 35 Fine. Lime-cement plaster for facades, can be applied manually and by machine. It has high vapor permeability, is not afraid of moisture due to the presence of special modifying additives. The maximum fraction of the filler is 2 mm, the layer thickness is 10-20 mm.

- AeroStone Plaster mix for aerated concrete and gas silicate based on cement, lime and polymer components. It has high vapor permeability, maintains a comfortable microclimate in the house. It is applied with a layer of 5-10 mm.

- Krasland "Thin-layer plaster". Plastic, water-, frost-resistant composition with cement, quartz sand, hydrated lime and modifiers. Allows to apply an elastic, non-shrink layer, not subject to cracking.

Stucco Tools

To finish aerated concrete blocks, standard tools are used that are suitable for other plastering works. You will need any convenient container for mixing the mortar, as well as a construction mixer or drill with a nozzle. The following devices will be needed:

- a plaster bucket or trowel for pouring mortar onto the surface;

- construction grater, trowel or trowel for rubbing the base;

- spatulas of various sizes, including angular and serrated, for applying mortar and processing walls;

- metal or plastic beacons for laying an even plaster layer;

- a rule or rail for smoothing the solution between the beacons and checking the quality of work;

- level for assessing the state of the plane and the installation of beacons;

- reinforcing mesh to strengthen the plaster layer;

- brush and roller for applying soil.

Features of plastering

Aerated concrete blocks are often brought to the customer immediately after production. During this period, a large amount of moisture is inside the blocks, which did not have time to weather. In addition, when applying plaster, moisture also seeps into aerated concrete, as well as liquid from precipitation.

Drying of aerated concrete walls should last at least 6 months, and in the same period, their main shrinkage occurs. The best option would be to leave the structure alone and not proceed with plastering for six months. Also, it is impossible to produce simultaneous plastering of walls from the inside and outside: this will lead to a violation of the microclimate in the house.

to contents ↑First, they finish the walls indoors, after a few months they begin facade work. In regions where the damp climate prevails, only highly plastic compositions with the highest vapor permeability are used. In any case, the ability to remove steam from the outer plaster should be higher than the inner!

How and with what to plaster aerated concrete inside the house

If you first treat the internal surfaces of the building, the moisture from the solution and the water that remains in the aerated concrete blocks can evaporate unhindered. If you ignore this recommendation, there is a risk of cracks and delaminated plaster areas. In addition, the house will constantly increase humidity, and condensate will accumulate between the aerated concrete blocks and decoration.

Masters use the usual technology of plastering or techniques to ensure complete vapor barrier.In the second case, a plastic film is attached between the layers of the solution, which greatly reduces the vapor permeability of the walls. Also, instead of the film, coloring of the finished finish with oil paint or impregnation with a special primer is used.

According to conventional technology, almost any mixture, including gypsum and for facade work, is used for internal plastering. The main thing is that their vapor permeability is lower than that of aerated concrete itself. In rooms with high humidity, waterproofing compounds or very dense mixtures are used (for example, standard cement plasters).

to contents ↑Foundation preparation

Aerated concrete without careful preparation differs in low adhesion to plaster mixes, besides it literally absorbs water from them. This material is very even and smooth, but sometimes there are large chips and dents on individual blocks. They are covered with glue for aerated concrete, which was used during installation. It is best to mix it with a small amount of concrete dust that appears when cutting blocks. After filling the recesses, the excess glue is removed with a spatula and allowed to dry. Badly sealed seams are treated with the same composition, then rubbed with a construction grater to remove flaws.

Further, as part of the preparatory measures, do the following:

- sweep away all dust and debris from the surface of the wall;

- if the blocks are too smooth, stick a thin fiberglass mesh.

Priming

Deep penetration soil with moisture-protective and firming properties is a mandatory tool, without which aerated concrete will deteriorate from the water that accumulates in it. After applying a primer on aerated concrete, a strong but flexible film is created that will prevent water from seeping in, but will not block the pores for the exit of fumes. Among other things, the soil will bind the dust and enhance the adhesion of aerated concrete with plaster. Most often, the following compositions are used as soil:

- "Aerated concrete-Contact-1";

- Knauf Grundiermittel;

- Siltek E-110.

The primer is applied in 2-3 layers, although in dry and warm regions you can limit yourself to even one layer. It is distributed on the surface with a roller or brush, continuous, evenly and with sufficient penetration of the base. After completion of work, not a single dry area should remain.

to contents ↑Beacon Installation

When the thickness of the finishing layer is more than 7 mm, installation of guides is required, which will allow plastering to be perfectly even. Lighthouses are fixed every 60 cm or at a distance slightly larger than the size of the rule. They are mounted on a solution that will be used for the main work, forming small piles from it and controlling the position with a level.

to contents ↑Throwing a "fur coat"

The easiest way to use the first (draft) layer is to use a construction hopper bucket. In its absence, an ordinary trowel is suitable, with the help of which fill the free spaces between the beacons. Start spraying the solution from the bottom of the wall.

to contents ↑Throw each portion as close to the previous one as possible. After processing a plot of about a meter square, the mass is leveled by the rule, moving it from bottom to top by oscillatory movements without strong pressure. Areas that remain poorly filled with stucco are plastered again.

First layer processing

After partial drying of the layer, the beacons are removed. If there is a financial opportunity to leave them, it is allowed not to spend your time on this stage. The fact is that after removing each guide, there remains a hole that will have to be additionally repaired and aligned. Nevertheless, in regions with a cold climate, beacons are sure to be removed, which in the future may become bridges of cold. After sealing the beacon holes, plaster a little with water and pass along it with a grater to remove irregularities.

to contents ↑Forming angles

To make the corners smooth, beautiful and to prevent the appearance of chips, you need to pay more attention to plastering.The ideal option is to fix the perforated profiles on the corners or trim them with pieces of fiberglass. Devices are attached to the solution, on top they are closed with another layer and rubbed with a grater.

Finish finish

The internal aerated concrete walls after applying the plaster can be finished in different ways:

- Painting. For this method of cladding, walls should be made as even, smooth as possible. For this purpose, use a building grater or grater. After applying a layer of acrylic or latex paint for internal surfaces.

- Decorative plastering. Without waiting for the main mortar to dry completely, a layer of decorative plaster is applied, patterns are made on it manually or with a textured roller, or an original pattern is created using a grater. Apply already tinted plasters or paint them after drying.

- Sticking tiles. For tiles do not finish, but immediately attach it to the glue after drying the rough layer of plaster.

to contents ↑

Plastering aerated concrete outside the house

If the front part of the building before finishing remains uncovered with insulation, its vapor permeability is not violated. Nevertheless, a system of additional insulation (foam, mineral wool) is often used, which prevents moisture from evaporating. In this case, the plaster composition with the highest vapor permeability is selected, and high-quality ventilation is mounted inside the house. Since the load on the external walls will in any case be large, reinforcement is indispensable here.

to contents ↑Surface preparation

Typically, aerated concrete blocks are laid on a special adhesive composition, and its excess protrudes from the wall plane. During the preparation of the base, they are planed with a construction grater or cut with a planer, or other convenient tools. Large cracks are closed with glue mixed with aerated concrete dust using a narrow spatula. They allow the base to dry well, then proceed to further work.

to contents ↑Padding

For the outer part of the walls, deep penetration primers, for example, acrylic silicate, are also used. They make the base water-repellent, but do not interfere with the evaporation of moisture. Apply 2-3 layers of soil with a complete intermediate drying, while in no case dilute the composition with water, but use in pure form!

to contents ↑Reinforcement and Alignment

Typically, a reinforcing sheet of metal or fiberglass with 0.1-0.2 cm cells is used to strengthen the finish. The grid is fixed on the applied layer of the solution with an overlap of 5 cm, the corners are trimmed with perforated corners in parallel so that chips do not appear on them. On the protruding layer of plaster spend a notched trowel. In the area of windows and doors, the reinforcing sheet is fixed in parallel with screws. After undertake the following:

- wait until the first layer dries (about 4 days);

- perform the second leveling layer of the plaster, wipe it to smoothness, allow to dry;

- make the last layer, which is ground with an abrasive mesh or fine sandpaper.

Finish finish

To form the topcoat, tinted decorative plasters are used or the already finished lining is painted with suitable facade paints. Mixtures with the effect of bark beetle, fur coat, sandstone are suitable for the processing of aerated concrete. Mashing is carried out according to the manufacturer's recommendations, which are always on the packaging of the material.

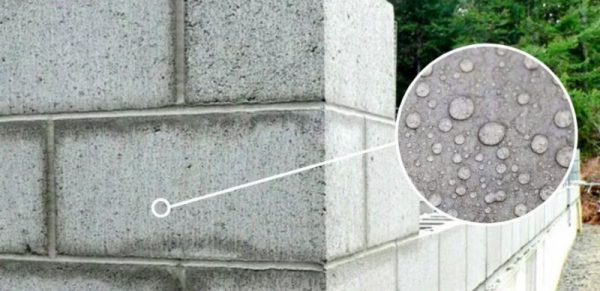

to contents ↑Hydrophobization

About a year after the plastering of aerated concrete, the coating is hydrophobized. As a water repellent, a special transparent composition can be applied on top of the finish, which penetrates the pores and creates a reliable water-repellent layer (for example, Neogard).Means of this type prevent the appearance of efflorescence, cracks, while serving up to 15 years.

to contents ↑Optimal conditions for applying plaster

In order for the quality of finish of aerated concrete walls to be high, it is necessary to observe the recommended temperature range during work (+ 5 ... + 30 degrees). In this case, the indoor air humidity should not be higher than 80%. With external plastering, one should not allow temperature drops below +8 degrees.

Do not work with facades in case of too damp weather, frost, wind or extreme heat. If it was not possible to do all the work in the summer, cover the facade with a primer and leave it until spring. Observance of all the above conditions will allow you to finish correctly, so it will serve for a long time without the need for repair.

aerated concrete must not be plastered with non-vapor permeable plasters! otherwise it will block his ability to give and receive moisture!