Cracks on the plaster are a serious nuisance that can happen immediately after the fresh mortar dries, or may appear on a long-standing finish. In any case, it is necessary to clarify how to repair cracks in the plaster on the wall and what methods can be used to get rid of them.

- Causes of Cracks

- Single layer wall treatment

- Primer neglect

- Use of low-quality or old mix

- Incorrect solution mixing

- Lack of reinforcing frame

- Wall pollution

- Clay and sand plaster

- UV and heat

- Moisture

- Cracks in damage to supporting structures

- Foundation deformation

- Building shrinkage

- How to prevent cracking

- Ways to eliminate defects on different surfaces

- Plaster repair

- Brick repair

- Repair of drywall constructions

Even professionals are faced with defects in cladding, so even before you start plastering the walls, you need to carefully consider all the nuances of the work.

Causes of Cracks

A network of small cracks or large defects can form both in houses with a long service life and in new buildings. The main reason for damage to the finish in old houses is considered to be deterioration of structures, subsidence of walls and their deformation. In new buildings, various errors in plastering, as well as the natural shrinkage of the main elements, can provoke a problem. Nevertheless, there can be several exact reasons for the appearance of cracks, and the task of the master is to find and eliminate their influence.

to contents ↑Single layer wall treatment

Wall alignment works are carried out in several stages. The process of plastering is not easy: during it 2-3 layers of mortar with different texture and consistency are applied to the surface. In this case, the technology will be respected and the risk of cracking is minimized. If the wall is finished with only one layer of plaster, after drying it can become covered with a grid of defects.

Primer neglect

Any plastering work begins with a thorough preparation of the foundation. After cleaning the surface, they begin priming - applying a primer (primer). This tool increases the adhesion force of the base with the plaster, and also contains antiseptic and fungicidal additives. As the primer with deep penetration dries, they begin to plaster. If you forget about the use of a primer, the plaster may crack.

Among other things, soil is called the middle plaster layer, which follows the spray. It adheres well to the wall and gives the surface extra strength. Skipping this stage of work is also impossible, because it is the primer layer that takes up most of the load when the walls shrink.

Use of low-quality or old mix

The use of fresh plaster, the expiration date of which is normal is a prerequisite for the quality of work. Old mixtures may lose some properties, as a result of their strength, wear resistance, adhesion are reduced.If the expiration date is approaching, it is better to look for another mortar.

Poor quality plastering is another possible cause of cracking. Cement in the solution must meet the standards, and its proportion should not exceed 1/3 of the total mass. In contrast, a small amount of cement causes the mortar to creep off the wall. It is good if polymer components are introduced into the composition of the plaster: such a mixture is more expensive, but an order of magnitude more elastic and less cracking.

Incorrect solution mixing

Dry building mixes always have detailed kneading instructions, which are reflected on the packaging. To prepare the composition, you need to take only clean cool water without impurities, strictly control its volume. It is also important to introduce the dry mass into the water in small portions and immediately mix the plaster with a construction mixer. After the initial kneading, it is necessary to leave the material under the lid, after a few minutes, beat it again, and only then apply as directed. If you do not observe the proportions or mix the plaster manually, it will be poorly applied and will crack in the future.

Lack of reinforcing frame

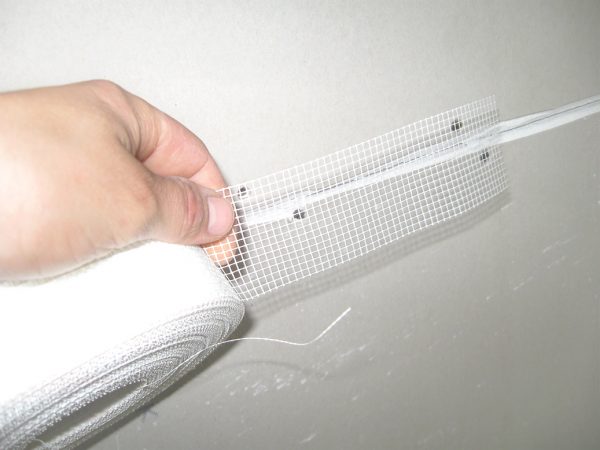

When the plaster is applied on fragile substrates, as well as on surfaces with seams, it can crack without additional reinforcement. Gluing of a sickle when plastering drywall, other materials when decorating under wallpaper is considered mandatory. The mesh will reduce the risk of flaking and cracking after drying. The thicker the layer, the stronger the reinforcing fabric should be. Most often, fiberglass materials are used, and there are also plastic and even metal sickles on sale.

Wall pollution

When the plaster cracks upon drying, the cause is often poor wall preparation before applying the mortar. Left greasy spots, dust, dirt reduce the adhesion of the material to the substrate, as a result of which it begins to exfoliate. Therefore, before plastering, it is important to thoroughly clean the walls with water and a detergent or solvent.

Clay and sand plaster

Clay-sand building mixtures are considered greasy due to the properties of clay. They are difficult to apply to walls, poorly smeared and do not always have a sufficient degree of adhesion. If the wall has many irregularities, it will be problematic to level it with similar plaster, and in places of bulges the material will completely peel off. It is recommended to perform rough leveling with cement mortars, and only then use clay ones.

In some rooms humidity is constantly increased, or temperature differences are observed. Cracks under these conditions appear more likely, since clay plasters do not tolerate moisture well. It is better to use them only in dry rooms, and in the bathroom and kitchen to decorate the walls with moisture-resistant polymer or cement compounds.

Beginners often make a mistake: apply too thin a layer of plaster (less than 0.5 cm). When it dries, moisture evaporates in a short time, and the material does not gain the necessary strength. In order for the process to proceed more slowly and evenly, the layer must be made thicker (from 1 cm). This will reduce the risk of delamination and cracking of the solution.

to contents ↑UV and heat

After applying the plaster, the wall should gain strength and strength. For this, optimal conditions are created in the room: the temperature is not higher than +25 degrees, the absence of drafts. It happens that direct sunlight falls on the coating, and this often happens during facade works.

In addition to the harmful effects of UV radiation, there is a rapid loss of moisture in the solution, as a result, the finish dries unevenly. The result is the appearance of a network of cracks after drying.It is better to carry out plastering work on the street in cloudy but dry weather, and close the windows with blackout curtains in the house.

Moisture

Excess moisture in any form is dangerous for plaster: it greatly violates the quality of the coating. Water can get on the finish in the following ways:

- from a solution if a lot of liquid was added during its dilution;

- from a wall that remained wet after priming or applying the previous plaster layer;

- from air (if the humidity indicator exceeds 70–75%);

- with a mismatch between the vapor permeability coefficients of the base and finish.

to contents ↑Any of the factors listed above can cause disturbances in the drying process of the plaster layer, as a result of which it will lose its integrity.

Cracks in damage to supporting structures

This usually happens in homes with significant wear and tear, the operation of which lasts for decades. Sometimes the situation is so serious that only major repairs of housing, including supporting structures, will help. First, the degree of destruction of the walls is assessed, then they are reinforced, and only then they begin to finish. If the base is not strong, the decorative layer will quickly crack.

Foundation deformation

In private homes, cracks can be caused by foundation problems. If it is deformed, it will inevitably affect the appearance and condition of the walls. In such a situation, it is necessary to repair the foundation, since without it all attempts to repair the cracks will not succeed.

Building shrinkage

Within 1-2 years, new buildings tend to shrink, and we are talking about concrete and brick buildings. Even the solution, which serves as a layer between the individual blocks, is able to dry out, which causes cracking of the plaster. If you use superelastic compounds to decorate new homes, such problems will not arise.

How to prevent cracking

In order to avoid troubles with the finished wall decoration, you must carefully observe the plastering technology at all its stages. Professionals give beginners a series of tips to help prevent cladding cracking:

- The air temperature in the house should be optimal - from +10 to +25 degrees. If the air is too hot, any plaster will crack. It is strictly forbidden to use heat guns, fan heaters and other devices to accelerate drying: they contribute to uneven drying of the walls.

- Drafts, direct sunlight in a plastered room should be strictly excluded. Otherwise, the quality of the finish will drop dramatically.

- Cement plaster is applied with a layer of about 2 cm. For gypsum plaster this figure may be slightly lower - 1.5 cm. If you plan to make thicker layers of the mixture, all work is performed after the beacons are installed. The use of reinforcing mesh, which will increase the adhesion force of the plaster to the substrate, will increase the work efficiency.

- There are standards for the thickness of the layer and relative to the base material. For example, even strong polymer compositions when applied to stone, concrete, brick should have a thickness of more than 5 mm. If wood plastering is carried out, the minimum figure increases to 9 mm.

- Before applying each next coat of finish, they check how firmly the previous one has grasped, whether cracks have appeared on it. Hoping to cover the cracks with a new portion of the solution is not worth it: they need to be fixed and the work redone.

- Different types of plaster have their own characteristics in mixing, dilution, application, drying, care. The manufacturer always indicates them on the packaging. Do not ignore such tips so as not to know the problems with the operation of the finish.

to contents ↑

Ways to eliminate defects on different surfaces

The decorative finish in the presence of cracks loses its attractiveness, its functionality also turns out to be reduced. Of course, you can glue the cracks with wallpaper, lay them with tiles, but under them the base will continue to collapse. Sooner or later, moisture will seep through the cracks, mold will start there, and the lining will begin to exfoliate in areas. Therefore, first you need to get rid of the cracks, and then continue the finishing work.

to contents ↑Plaster repair

Most often, plastering the walls is carried out using cement-sand mortars, which without additional additives have too little elasticity. Therefore, cracks on such compositions are not uncommon. Usually they are formed with a very thick layer of plaster, due to excessive humidity or dry air, as well as with a high sand content in the product.

Immediately after drying, cement plasters should be primed and putty, but sometimes small cracks appear even after such a multi-stage lining. A good option for eliminating defects is to remove the top layer and reinforce the wall with a spider line - painting glass canvas. Fiberglass mesh is also suitable for this purpose.

After gluing the reinforcing material on a special glue, it is primed and putty. You can also use cullets for painting, however, such a cladding is not suitable everywhere.

Other options for repairing plaster with small cracks:

- A mesh of tiny defects is treated with deep penetration impregnation. It will strengthen the layer of plaster, will not allow cracks to grow. After the soil has dried, a thick layer of dispersion paint is applied and the finishing work is started.

- Small areas of damage to the plaster are covered with a thin layer of cement and PVA glue in a ratio of 1: 1. The tool is applied with a brush, smeared well, allowed to dry.

- In new buildings on the walls, large, deep cracks that are able to reach the base are closed as follows. First they are embroidered - the edges are knocked down with a chisel and hammer at an angle of 45 degrees. Remove weak adjacent pieces of plaster, residual dirt, dust. A solution is prepared on the basis of sand, cement, fine gravel or crumb brick (for outdoor work, a little slaked lime is introduced into the composition). The crack is sprayed with water from the spray gun, close it with a spatula, filling all the voids with plaster. Excess cut off flush with the wall. After drying, the area is ground.

- Wide through cracks are covered in the same way, but formwork is done to prevent the solution from flowing out. Prepare it from plywood, boards so as to cover the entire damaged area. They screw the mold with screws to the wall and remove it only after the plaster has finally hardened.

Brick repair

If the cause of cracks is a violation of the masonry technology, then completely get rid of the problem will only be a radical way. Otherwise, the kinks will appear in the masonry between the individual elements and, as it were, tear the plaster from the inside, gradually deepen, expand.

During the repair, all plaster is removed from the crack and from adjacent areas, the defect itself is expanded to masonry. Next, close the problem area with such means:

- Cement based mortar. Prepare a composition of sand, cement, dilute it to the consistency of thick sour cream. You can also purchase dry tile adhesive and prepare the solution according to the manufacturer's instructions.

- Suture sealant. They buy high-quality acrylic or polyurethane sealant and glue gun, fill the crack to the base. The excess is removed with a rubber spatula dipped in soapy water.After the sealant has dried, the repaired area is plastered again. Silicone sealant is not suitable for this purpose, since plaster almost does not adhere to it.

Repair of drywall constructions

Gypsum boards are a popular, reliable finishing material that is often used to align curved walls. It is easy to work with him, but beginners often make mistakes that cause cracking of the GKL finish. For example, with improper installation or weak fixing of the frame, the sheets are in an unstable position, so cracks are constantly formed. Only one way out: remove the GCR and attach again.

When defects on the finish appear as a result of the flood, increased humidity, the decision will be even more cardinal: you will have to change the deformed sheets of drywall. The problem with improper sealing of joints between GCRs is easier solved. The old putty is removed from them, a strong reinforcing tape is glued, the glue is allowed to dry and putty again. An even more reliable way is the full reinforcement of GCR with fiberglass, however, this option will cost more and will be quite labor-intensive. After pasting, the fiberglass needs to be putty and sanded, and only then proceed to the finish.

Before starting the plastering work, it is important to study in detail all the features of the walls and operating conditions, specify the age of the house and determine the type of decor. This will help to comply with the nuances of technology and prevent the appearance of cracks in the plaster, as well as increase the service life of the finish at times.