Hard putty for a wooden floor - a material designed to eliminate minor defects, seal small cracks, level the work surface. Its main purpose is to play the role of an intermediate layer, which contributes to a better quality application of the finishing composition. After solidification, the mass is able to hide the irregularities of the flooring made of wood.

- What should be a quality mixture

- Varieties of putties

- Acrylic

- Oil

- Polymer

- Solvent based

- Self-preparation of the composition

- First option

- Second option

- Third option

- Performance of work

What should be a quality mixture

The main feature that wood putty has on wood for the floor is the ability to carry out several types of work with it:

- surface leveling;

- closing cracks between the boards;

- filling seams when assembling parquet;

- redecorating a wooden flooring.

With the help of a high-quality and correctly selected mixture, it is possible to effectively carry out all the work associated with sealing joints during the laying of the components of a new floor covering. The composition will also allow you to prepare a wooden surface for laying linoleum or laminate.

to contents ↑Varieties of putties

The modern market of building materials provides the consumer with the opportunity to choose any desired composition, focusing not only on its price, but also on quality. The variety is so great that, before proceeding with the selection, you should familiarize yourself with some of the features of the proposed materials. It depends on them how high-quality, reliable and durable the coating will be.

to contents ↑The wooden floor is the cleanest environmentally friendly coating. It is able to delight the owner’s look over the years, periodically requiring only a small cosmetic repair. It is for this purpose that special putty has been created and is being successfully applied.

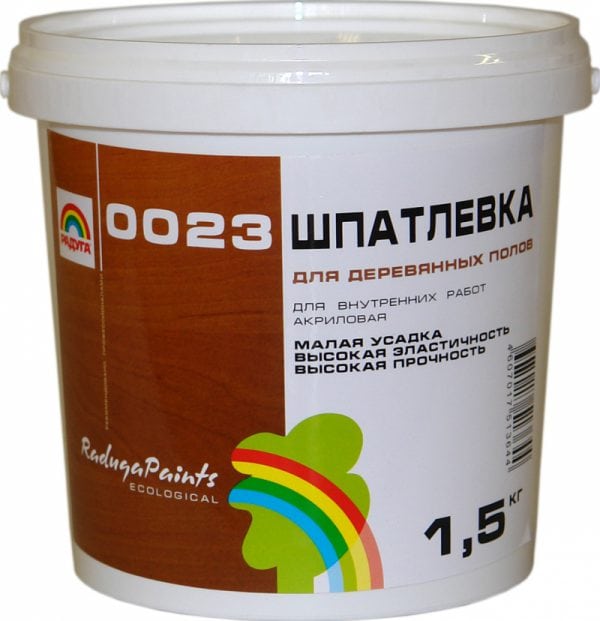

Acrylic

This mixture for the treatment of wooden floors is intended for sealing joints, joints or cracks found on the surface. It is very convenient for her to grout the seams when laying a new coating or to restore a long-installed one. It has excellent moisture resistance and is completely harmless to the health of those living in the apartment.

During the work, the acrylic mixture shows itself as flexible and easy to use, fireproof and resistant to damage. It easily lays on the surface only if the floors are thoroughly cleaned of dirt and dried.

to contents ↑Oil

It differs in that it dries for a very long time. She found her fans because of the elasticity and ease of operation, but they use it only in cases where there is no need to complete the process of laying or repairing wooden floors in the shortest possible time.

Polymer

It is made on the basis of water and serves to fully level the surface and fill cracks and cracks. The main distinguishing feature is that such a putty composition dries quickly enough, does not crack and does not fail after some time.

Polymer putty is not used when working with cork and floorboard.

to contents ↑Solvent based

Mixtures for puttying are made with a solvent, in which wood dust is present. Its rather small particles are carefully mixed with the adhesive to obtain a homogeneous mass, the consistency of which resembles thick sour cream. It is perfect for working with a wide variety of species, including exotic ones, of wood. It is a success with the masters of laying parquet. The solvent on the basis of which this composition is made allows the putty to dry very quickly and gain a fairly high degree of strength in a short time. All of these qualities have made such a composition most in demand in the construction of a warm floor.

to contents ↑Self-preparation of the composition

When deciding how to putty a wooden coating before starting laying the laminate, many consumers come to the conclusion that it is better to prepare the mixture for work. The whole point of the process is to first strengthen the floors (if there are "walking" boards), then build a frame of thin bars, and then proceed to fill the free space between the lags with a composition made on the basis of PVA. This is a great way to level the floor before laying laminate or linoleum.

to contents ↑First option

To prepare the composition, you need a sufficient amount of fine wood sawdust and PVA glue. The thick mixture is poured between the bars, leveled with a rule or a large spatula and allowed to dry thoroughly. After drying, the resulting surface (which can be considered ready for laying a new coating) will be quite stiff and strong, there will be no cracks and irregularities on it.

to contents ↑Second option

Animal glue (10% of the total mass), liquid drier (2.5%) and turpentine or glue kerosene (12.5%) are used. This means that to prepare 1 kg of the mixture you will need 200 g, 50 g and 250 g of the listed substances, respectively. This putty needs to be welded:

- Heat the animal glue, add soap to it.

- Slowly, constantly stirring, introduce drying oil, turpentine and drier into the resulting hot mixture.

- When the mixture thickens and becomes a homogeneous mass, carefully introduce a small amount of chalk.

Stir the composition during heating until the putty resembles thick sour cream. It can be putty until the moment when the prepared putty begins to cool. To warm the cooled mass, it is enough to use a water bath, which will provide a gradual and uniform heating.

It is important that self-prepared putty meets the basic requirements for such formulations. It must be flexible and durable. In addition, the highest quality of such a mixture is high adhesion. It is she who guarantees the long term of exploitation of the floor without swelling and cracking. An equally important detail is the uniformity of the mass.

to contents ↑Third option

There is another simple recipe for making putty on wood with your own hands. It is prepared on the basis of PVA glue. To implement the plan you will need:

- PVA glue;

- water;

- dry mix for finishing putty.

In the prepared container, it is necessary to pour glue (about 1/3 of the total estimated mass of the composition), add 2/3 of water to it, then gradually introduce any finishing putty, not forgetting to constantly stir. Dry putty should be introduced in small doses, thoroughly kneading, until a homogeneous elastic mass is obtained.

Now it can be applied evenly on the surface to be restored and allowed to dry completely. It will be possible to start processing with fine sandpaper no earlier than after 12-15 hours.After restoration using such a mixture, the old surface will look perfect, and any paint will lie on it perfectly.

to contents ↑Performance of work

Puttying the floor with your own hands is an occupation that requires certain skills. Using puttying, you can qualitatively update the existing flooring made of wooden boards during cosmetic repairs. Even repeated application of the paint composition to the surface requires preliminary puttying, which will help to make the floor even and smooth.

You can work only on a dry wooden board, from which not only dust and dirt are removed, but also the previous coating. When preparing the floor with your own hands for puttying, it is necessary to carry out degreasing.

Putty is applied in a thin layer using a special steel spatula. It is important that during the work the mixture fills all the existing cracks and cracks. You should pay attention to the thickness of the filler layer, because after complete drying the floors will have to be sanded. The number of layers of the applied composition depends on the degree of damage to the coating. Each subsequent (after it completely dries) is again polished. This continues until there are no bumps and depressions on the floor surface.

The use of wood putty is not always suitable for existing flooring. Therefore, after all the gaps between the boards are filled, plywood sheets are laid on top of the old coating, and linoleum is laid on them or a laminate is laid.