Cold galvanizing technology is actively used in modern industry. It has proven itself in the Russian market, and therefore is used in many fields. It is important that the composition provides a really high-quality, durable, reliable protection of metal surfaces from the external environment.

- No 1 Corrosion Protection!

- What are the benefits of cold galvanizing?

- Detailed description

- Application area

- Application Method

- Packing

- Additional Help

We present you the cold galvanizing "AKTERM-ZINK®" - a high-quality composition that guarantees 100% tread action. Our company has mastered its own production of a one-component thin-film zinc coating that has passed all the necessary tests. The Akterm enterprise provides high consumer properties of AKTERM-ZINK® cold galvanizing and provides favorable conditions for the acquisition of this composition.

to contents ↑No 1 Corrosion Protection!

A humid environment is harmful to metal products. With prolonged contact with the liquid, corrosion forms on the surface, which gradually destroys the structure of the product, rendering it unusable. Cold galvanizing AKTERM-ZINK® helps to eliminate direct contact between the liquid and the metal coating, therefore, the likelihood of corrosion is reduced to zero.

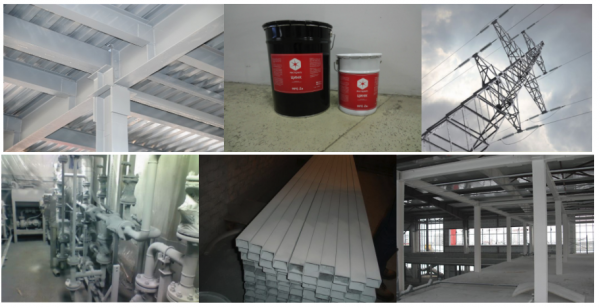

AKTERM-ZINK® is a professional tool suitable for processing both small products and large metal structures used in construction and various industries: at railway facilities, in the energy sector, oil and gas complex, etc. A one-component composition forms a thin film , preventing the harmful effects of negative environmental factors.

The Akterm cold galvanizing technology has 3 active effects:

- barrier function;

- inhibitory effect;

- electrochemical protection.

In practice, the treatment of metal surfaces with this composition helps to avoid the appearance of rust, thereby extending the service life of products and structures, reducing the cost of maintenance.

to contents ↑

What are the benefits of cold galvanizing?

The AKTERM-ZINK® technology has many advantages, and most important of them is ease of processing. The advantages of the composition include:

- lack of need for preliminary preparation of products;

- a simple application method that allows the use of AKTERM-ZINK® even to untrained workers;

- the possibility of applying to both machined and rusty surfaces.

This “AKTERM-ZINK®" differs from the hot-dip galvanizing technology. In fact, the use of this method helps to save time on the dismantling of structures, their processing and subsequent assembly.

to contents ↑Detailed description

The one-component composition has a porous structure. It is suitable for application on products of any size and shape, which does not limit the scope of AKTERM-ZINK®.The composition is compatible with other technologies for protecting metal surfaces: it can be applied to products that have already undergone the process of hot galvanizing.

Other features of AKTERM-ZINK® include:

- Long service life. With proper application, a thin-film zinc coating lasts for 35 years, this period does not depend on the level of atmospheric precipitation or climatic characteristics of the region.

- Smooth and pleasant to the touch texture. The processed metal products acquire a uniform color, and the coating becomes completely smooth, without rough blotches and protrusions.

- Contains up to 96% of the active substance. This helps to achieve an excellent effect the first time, eliminating the need for repeated processing of metal surfaces.

- Resistance to a wide range of negative factors. The composition of AKTERM-ZINK® is insensitive to fresh / salt water.

to contents ↑It should be noted that the top layer of AKTERM-ZINK® after application and drying retains its elastic properties. Due to this, it does not crack under sharp changes in the temperature of the environment. These indicators are stored in the range from –60 to +150 degrees Celsius.

Application area

The performed technological tests and accumulated experience show that the composition of AKTERM-ZINK® is optimally suitable for processing:

- metal elements of vehicles;

- tanks for domestic and industrial liquids;

- large metal structures - bridge and crane supports, building frames;

- bearing racks of gas and oil pipelines;

- metal pipes of various diameters and types.

This list shows that the cold galvanizing of AKTERM-ZINK® is applicable in mechanical engineering, construction, in the construction of port facilities and many other areas. Due to the ease of application, the composition is often used in everyday life, as well as in workshops and in small enterprises, including factories that produce forged products.

to contents ↑Application Method

The use of AKTERM-ZINK® cold galvanizing technology does not cause any difficulties. The composition has a liquid structure and is applied to a metal surface using:

- roller;

- brushes.

On an industrial scale, spray guns with an upper tank position can be used. This simplifies the supply of the composition and its application to the surface, reducing time and financial costs. It is necessary to apply the product at a temperature of –20 ... +50 degrees Celsius. For best results, it is recommended to apply 2 coats. Drying time - 10-60 minutes.

to contents ↑Packing

For the convenience of storage, transportation and use, the single-component composition “AKTERM-ZINK®” is packaged in metal buckets, the volume of which reaches 3, 10 and 20 liters (from 6 to 40 kg, respectively).

to contents ↑Additional Help

Due to the elastic structure, the composition of AKTERM-ZINK® acquires increased resistance to abrasion. This helps to use cold galvanizing technology to process not only static but also movable structures. Due to the safe composition, the method is used in industrial and civil engineering. Suitable for all macroclimatic regions, which is an important difference from similar tools.

If you decide to purchase AKTERM-ZINK® at an affordable price, then call our office at the numbers:

- for Moscow +7 (495) 532-05-26;

- for St. Petersburg +7 (921) 302-59-59.

You can also leave a request on the site using the feedback form. An employee of the Akterm company will call you back at a time convenient for you, advise on all issues regarding the use of AKTERM-ZINK® and calculate the cost of the wholesale and retail lot.

What is the wholesale price (according to the price list)? How can shipping to Kazakhstan and Kyrgyzstan be possible?