Manufacturer Sika (Switzerland) produces a variety of types of sealants based on polyurethane and other components. The products are intended for professional and home use, characterized by excellent quality and moderate cost. Sicaflex sealant is especially popular on the market: it is well suited for exterior and interior use, characterized by durability and high strength.

- Description of the tool and scope

- Characteristics of sealants

- Technical specifications

- Sealant mechanical properties

- Expense of funds

- Sealant Application - Features

- Terms and conditions of storage

- The main advantages of sealants

- Instructions for use

- Preparatory stage

- Seam filling

- Bonding parts with sealant

- Tool cleaning

- Rules and restrictions

- Restrictions on the conditions of use

Description of the tool and scope

Sicaflex is a one-component suture sealant, universal flexible polyurethane adhesive, cured by moisture from the air. Sikaflex 11FC + is suitable for all types of work in homes, apartments, other buildings, suitable for outdoor use. The possibilities of its application are diverse:

- filling of vertical, inclined, horizontal seams;

- soundproofing between concrete and cladding;

- fastening prefabricated elements, fixing the upholstery;

- gluing steps, window sills, sills, skirting boards, panels, door parts;

- sealing joints between sections in wooden and metal structures;

- arrangement of ventilation systems, emergency protection;

- elimination of voids;

- sealing and thermal insulation of pipes.

Characteristics of sealants

The Sicaflex sealant is represented by a one-pack composition, which is completely ready for use, you just need to cut the nose and put the container in the gun. After hardening, the sealing joint maintains elasticity, therefore it does not crack with time even under the influence of vibration, deformation vibrations. Other sealant characteristics:

- high adhesion with most building materials (concrete, metal, wood, PVC, ceramics);

- resistance to negative factors: precipitation, friction, scratching, shock;

- no harm to metal - the sealant does not provoke corrosion, therefore it is suitable even for materials subject to rust;

- comfortable to apply texture, not forming sagging when working with vertical bases.

to contents ↑After mounting structures using this sealant, additional treatment with cement or other bonding solutions will not be required - Sicaflex reliably glues all elements and serves for many years.

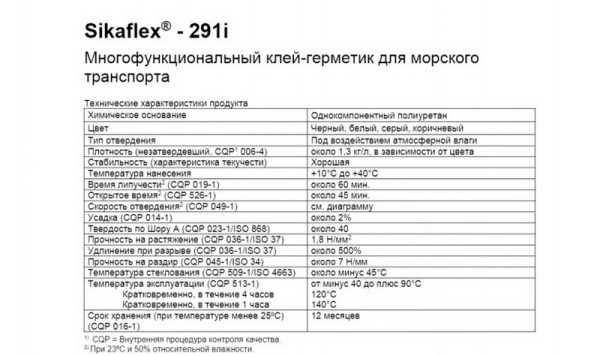

Technical specifications

When choosing a sealing composition, it is necessary to evaluate its technical characteristics. At Sicaflex sealant they are as follows:

- the density of the solution is 1.35 g / cubic cm;

- time to film formation at a temperature of about +23 degrees, humidity 50% - 65 minutes;

- elasticity - 0.6 MPa;

- hardness (Shore) - 35 A;

- elongation at break - 700%;

- the temperature during operation of the seam is from –40 to +80 degrees.

The composition should be applied at a temperature of + 5 ... + 40 degrees, otherwise its technical parameters may change, adhesion may decrease. The curing rate of the sealant is quite high (2 times more than other brand products - about 2 mm seam per day).

Sealant mechanical properties

Sikafleks can be used at a construction site, in the repair of structures that are characterized by small shifts, and where a high rate of elasticity is required. It withstands deformations up to 15%, without losing properties. Characteristics of the composition:

- allows to perform waterproof joints of high strength;

- provides optimal abutment, completely closes even the smallest cracks;

- suitable for all types of seams, and for pipes, upholstery, can replace glue;

- after drying it is suitable for grinding, drilling, other types of machining;

- has tremendous tensile strength;

- Available in different colors: white, gray, black.

to contents ↑If the sealant is applied to a smooth material, it is better to first prime the base - this will seriously increase the degree of adhesion. Sikaflex is perfect for joints from 10 to 35 mm, although it can also be used for the smallest cracks, and with sealing cords for wider ones.

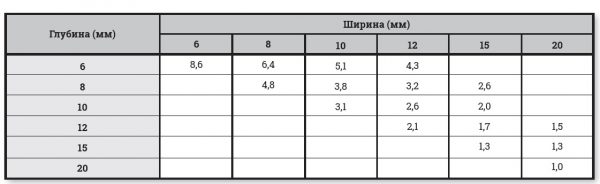

Expense of funds

Sealant requires proper application, observing the depth and width of the seam. For joints on the floor, the ratio of these indicators should be 0.8 / 1, for facade joints - 2/1. Material consumption varies from 0.2 to 0.6 kg / sq. m and depends on the conditions of application, the composition of the base, type of construction.

Sealant Application - Features

For ease of work, you should purchase a gun for sealant - the device should be suitable for 300 ml tubes. Also, the product is available in "sausages" of 600 ml, for which a special gun is intended. The tube nose is placed in the tool so that the composition is fed with maximum contact with the inner surface of the joint. This will prevent air from entering the seam and prevent the formation of voids.

To improve adhesion and accelerate solidification, Sicaflex is applied with a layer of optimal thickness without making it too voluminous. To make a straight line, the borders of the seam are pre-glued with masking tape. The main thing is to remove it until the sealant has solidified, otherwise the seam may be damaged.

Terms and conditions of storage

The sealant is suitable for 12 months from the date of manufacture (the date of manufacture is indicated on the package). Storage conditions must be observed:

- temperature from +10 to +25 degrees;

- dry room;

- the exception of freezing, exposure to direct sunlight.

The main advantages of sealants

Sicaflex is ready for use, therefore, additional containers, mixing of the components or the introduction of a hardener are not required. The sealant cures without the formation of bubbles, its consistency is optimal for any seams. The tool is considered universal: suitable for sealing joints and use in the form of glue. Other advantages of the composition:

- elasticity;

- suitability for deformable and stable substrates;

- no harm even to delicate materials;

- high mechanical resistance, weather resistance;

- excellent resistance to wear and aging;

- anticorrosion properties;

- vibration absorption, shock.

to contents ↑

Instructions for use

Before work, it is important to qualitatively prepare the surface, otherwise the degree of adhesion of the product with the base will decrease.

Preparatory stage

All contact surfaces must be clean, degreased, dry. Any residual dust, dirt, as well as fragile, crumbling particles and traces of cement milk, greases should be removed. Non-porous, smooth substrates are recommended to be treated with a special Sika Cleaner-205 cleaner, and then apply Sika Aktivator-205 adhesion promoter with a clean rag. If necessary, remove contaminants by fine abrasive grinding.

When working with smooth surfaces and PVC, the Sika Primer-215 primer is used, which is applied with a regular paint brush to completely dried substrates. Before sealing, wait at least 30 minutes, but not more than 8 hours from the end of the preparatory work.

to contents ↑Porous materials (concrete, cement mortars, bricks) can also be primed with primer to reduce the absorption of the sealant. The primer does not replace thorough preparation and removal of dirt, grease, but it improves the strength characteristics of joints and increases their service life.

Seam filling

In wide or too deep seams, a cushioning cord of polyethylene or other material is placed, introducing it to the desired depth. After they take a gun with inserted sealant and squeeze out the composition, forming an even seam and excluding air. Remove previously pasted masking tape while the sealant is still soft. Smooth the product with a spatula moistened with water, but better with a special smoothing fluid, which helps to make the joints perfectly smooth.

Bonding parts with sealant

Often, Sicaflex is used as an adhesive. Before gluing, both contact surfaces should be well cleaned and sanded if necessary. The product must be applied in stripes or dots with an interval of 1–2 cm, press the product with your hands, fixing it in the required position.

If required, you can fix the structure with masking tape, wedges, supports for several hours after applying the sealant. If it is necessary to change the position of the parts, it is allowed to detach them from each other, but only for a few minutes, while the sealant has not yet seized. It is possible to put the product into operation after 1–2 days, the exact drying time depends on the thickness of the adhesive layer.

Tool cleaning

All used tools must be cleaned immediately after completion of work. Organic solvents or special products Sika Remover-208 or Sika Top Clean-T are used for this. After the sealant has dried, it will be necessary to remove its residues mechanically.

Rules and restrictions

There are a number of rules that must be followed when performing sealing work with Sicaflex:

- It is not necessary to apply a covering layer of material that does not have sufficient elasticity to the dried seam.

- The white sealant may turn yellow under the influence of ultraviolet radiation or various chemicals, therefore, if it is necessary to maintain the aesthetics of the seam, it is better not to use the product in appropriate conditions (the technical characteristics of the sealant will not change in any case).

- Before performing the sealing of natural or artificial stone, it is worth trying the work in a small area to check the reaction of the material.

- Sikaflex cannot be used on glass, bitumen, rubber, substrates containing diene monomers, propylene - the adhesion will be poor, and the sealant layer will not last long.

- Sikafleks is not suitable for surfaces on which solvents, oils, fats, plasticizers can appear - the seam will quickly collapse.

- The sealant is not used for working with swimming pools, as well as for seams in water or under high pressure.

- Before the joint is completely solidified, it is necessary to exclude the ingress of alcohols, isocyanates, cleaning substances, solvents and diluents on it.

to contents ↑

Restrictions on the conditions of use

The temperature of the environment and the base during operation with the sealant should be within + 5 ... + 40 degrees, and for the surface to be treated, it must be 3 degrees above the dew point. In order for the sealing joint to be strong and hold well, the base must be dry. Under these conditions, Sicaflex sealant will last for 5–10 years without any complaints.