High-quality soundproofing of the premises plays a huge role in the quiet life of the owners. It helps reduce the intensity of noise from the street and from neighbors, providing much-needed silence. As a soundproofing agent, you can use the so-called acoustic sealant, but it will be effective only with the right selection and application.

Features of sealants

Any sealant is a paste, gel or emulsion based on polymer compositions and is intended for sealing and thermal insulation of various surfaces. Some compounds have found their application in another direction, to create a soundproof layer.

Most often, vibroacoustic sealant is recommended for use in the construction and repair of wooden houses. It is applied in the gaps between the logs, timber, boards from the outside and from the inside, which seriously reduces the noise level. In addition, each soundproofing sealant is capable of absorbing and leveling vibration, and this increases the service life of the structure.

to contents ↑Varieties of funds

Silicone sealants are best suited as soundproofing agents. After drying, they retain elasticity, are not subject to cracking, crumbling, can be used for joints of any size and depth. Acrylic sealants are less popular: they become quite hard after polymerization, not too plastic, and also are not suitable for outdoor work because of their low moisture resistance.

Both foam and polyurethane sealant will help reduce noise levels. These tools are not suitable for the formation of internal seams, but can be used in conjunction with an acrylic or silicone compound. When choosing a sealant for sound insulation, the following factors should be considered:

- packaging integrity;

- normal expiration date;

- tightness of a cover;

- environmental friendliness.

Composition and properties

Vibroacoustic sealants, as a rule, are made on the basis of modified silicone resins with the addition of organosilicon components. The latter increase the strength of the composition, increase its service life.

A good sealant has the following properties:

- reliable sealing, regardless of the thickness of the seam;

- excellent protective qualities;

- lack of aggressive effects on metal and other materials;

- resistance to moisture, temperature changes, solar radiation;

- high adhesion and compatibility with natural minerals, cement, glass, and other building materials.

Acoustic sealant must have a high density of the surface layer, otherwise it will not be suitable for sound insulation.

to contents ↑The high-quality composition can process joints and seams during the installation of soundproof panels, and can be used on frame structures and floor coverings.

Popular brands

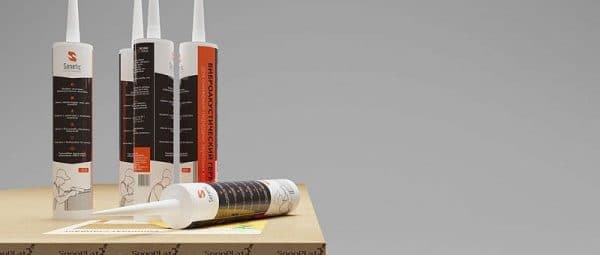

The most famous sealant with the ability to soundproof buildings is Vibrosil. It is widely used in the installation of soundproof structures, it is used to form joints of different thicknesses and lengths, and has excellent vibration-proof properties.

Other advantages of the composition:

- does not provoke metal corrosion;

- tolerates moisture and direct exposure to water;

- not afraid of temperature changes;

- Suitable for alloys, metals, wood, glass, concrete, brick.

Other popular sealants in the domestic market are:

- MaxForte. Designed for sealing joints, seams, various holes in walls, floors, ceilings. Seriously reduces the noise level, vibration load, acts as a damping layer. It is easily extruded and applied, has high adhesion to GKL, brick, concrete, plaster, plywood, glass, plastic. Contains mold and mildew inhibitors.

- Soundguard Professional product in various packs (310 ml, 600 ml 7 kg). Contains acrylic and modifying additives, suitable for all building materials. It has thixotropic properties, therefore it does not flow along inclined and vertical bases. Highly attenuates the transmission of sound vibrations and vibrations.

- Green Glue. Soundproofing compound based on latex polymer, which can eliminate up to 90% of noise. It can be applied in a thin layer (from 0.5 mm). Designed primarily to fill the space between the wall and decoration materials. Does not contain formaldehyde and other harmful substances, does not emit odor.

- "Acfix". Acrylic acoustic sealant designed to create a sound barrier to protect the house from smoke and humidity. It is characterized by the absence of a tendency to ignition, a slight smell, ease of application. It does not shrink, it helps to seal joints and crevices, to seal air ducts, cable ducts, walls, floors, ceilings, windows and doors.

Application Rules

First, you need to clean the contact surfaces from dirt, dust, degrease, get rid of all poorly fixed coatings (paint, falling plaster). After that, it is recommended to paste both ends of the joint with construction tape to apply the sealant more beautifully, evenly. Further, the procedure will be as follows:

- cut off the tip of the tube at an angle of 45 degrees, put the tube in the gun;

- fill the seam with sealant, moving the gun evenly, without jerking;

- immediately remove excess funds and remove masking tape;

- if necessary, clean the edges of the seam again;

- moisten the rubber sponge with water, gently smooth the surface of the seam (strictly before the composition hardens).

Applying acoustic sealant is an easy process that can be done independently. Strengthening noise insulation will certainly affect the quality of life in the house, so it is better to produce it already at the stage of rough finishing, while not saving on the sealant itself!