After the construction of the house, the process of its shrinkage inevitably begins. During this period, material deformations occur, cracks and cracks appear. Without sealing, drafts will walk around the building, mold will settle from excess moisture. Previously, caulking was used to warm buildings, but today there is a more modern product on sale - a sealant for wood, which fills seams, eliminates cracks and helps to significantly improve the climate in the home.

- Why is it necessary to seal log cabins?

- Sealant Requirements

- Types of wood sealants

- Acrylic Sealants

- Silicone sealants

- Polyurethane Sealants

- Bitumen products

- Color palette

- The choice of sealant for a wooden house

- Sealing technology for interventional seams

- Surface preparation

- Sealant Application

- Cracking

- Wood Sealant Manufacturers Overview

Why is it necessary to seal log cabins?

When laying timber, logs, and other building materials, accurate fitting of elements is almost impossible. No matter how high-quality the house is built, between the details of the log house there will remain gaps - the so-called "cold bridges". Sealing the joints is necessary, otherwise the holes will expand, the material will begin to collapse and rot. This process is particularly intense in the first years after construction, when there is a natural shrinkage.

If you correctly use sealant for a wooden house, you can achieve these effects:

- reduction of heat loss;

- draft prevention;

- optimization of temperature, humidity and microclimate in general;

- saving money on heating;

- prophylaxis of the reproduction of fungi and mold.

Modern wooden buildings are processed according to technology. warm seam, which is suitable for different types of buildings made of timber, logs. The technique involves the use of special suture sealants, with the help of which both the cracks between the logs and cracks in the wood are closed.

to contents ↑

Sealant Requirements

In construction stores, a large assortment of tools that are suitable for sealing log cabins is presented. They differ in composition, properties, technical parameters. A good sealant for the seams of a wooden house has the following qualities:

- sufficient elasticity, extensibility, the ability to adapt to the deformation of the base material, the absence of cracking and crumbling;

- strength, dense texture, reliable gap sealing and heat retention;

- resistance to water, high humidity, temperature extremes, ultraviolet, suitability for outdoor use;

- long service life.

Types of wood sealants

Sealant for the log house can be purchased in a convenient form and the desired volume depending on the needs of the user. Funds are presented in file packages, buckets, banks, tubes. The composition of the sealants are divided into four groups: silicone, acrylic, polyurethane, bitumen. All of them are well suited for wood and meet the necessary parameters.

to contents ↑Acrylic Sealants

Most often, it is acrylic sealant that is used to warm the log cabins. Such a tool has a lot of advantages:

- a high degree of adhesion with wood, as well as with other materials: concrete, plaster, brick;

- elasticity, maintained over many years of service, the ability to adapt to the compression and stretching of wood;

- moisture resistance, elimination of moisture penetration into the structure;

- ease of operation, the ability to seal joints even by a beginner;

- lack of solvents in the composition, environmental friendliness;

- the permissibility of staining the seam after drying;

- tolerance of temperature differences, application for the treatment of baths, saunas;

- the presence of fungicides in the composition, an obstacle to the reproduction of harmful microorganisms.

Average technical indicators that characterize acrylic sealants:

- curing speed - 3 mm / hour;

- the formation time of the surface elastic film is 5–20 minutes;

- mass density - 1.65–1.75 g / cu. cm;

- operating temperature - from –25 ... 30 to + 80 ... 100 degrees.

Due to the ability to effective moisture and heat insulation, with the help of acrylic sealants it is possible to strengthen any joints, including sedimentary ones (they are designed in houses divided into zones of different floors). When working with acrylic sealant, it is important to strictly follow the instructions. The quality of the seams will seriously suffer if you apply the composition in rainy weather or at temperatures below +10 degrees.

to contents ↑Acrylic-based color sealant is quite expensive, so it’s better to buy white products and stain them after hardening. If the joints are constantly exposed to direct sunlight, they can crumble over time, since acrylic is not too resistant to UV radiation.

Silicone sealants

Silicone-based products are considered universal and are excellent for indoor and outdoor use. The highest quality sealants last up to 40 years, which is comparable to the life of the wood itself, so you do not have to regularly repair the building.

Silicone sealant for timber perfectly adheres to wood, other building materials, penetrates the structure, closing even small cracks. Silicone or artificial rubber is a moisture-resistant substance, although under a strong stream of water it can be washed out of the base. Such sealants are well tolerated by ultraviolet radiation, are not afraid of temperature extremes from –50 to +150 degrees or more, they can be used in bathhouses.

The disadvantages of silicone products include the difficulty with staining. Paints and varnishes most often roll off such surfaces, so it’s better to immediately select a color composition than try to change the shade of the finished seam. In addition, after applying the paint, the elasticity of the silicone is greatly reduced, and when the wood is deformed, the sealant may crack.

to contents ↑Polyurethane Sealants

Polyurethane-based products are also suitable for sealing gaps in a wooden house. They have high moisture resistance: they easily tolerate both high humidity and direct contact with water, are not afraid of precipitation. Polymer compositions withstand the effects of ultraviolet radiation, temperature changes, the influence of wind, chemicals.

With the course of deformation processes that are inherent in every new log structure, polyurethane sealants do not break, do not crumble and do not shrink. Usually they are used for finishing external joints, since they contain toxic solvents (after drying the sealant, the latter cease to stand out).

to contents ↑Bitumen products

Mastics based on bitumen and rubber are considered the most moisture resistant of the entire range of sealing agents. Due to this property, they are used in the dampest places: basements, on the roofs of wooden houses. Bituminous mastics are rarely used to seal the main joints of the log house, and when applied to the ends, they can do much harm.

Due to vapor tightness, such compounds clog the capillaries of the tree, as a result of the logs crack, and the microclimate in the house is disturbed. Also among the minuses of bitumen sealants are:

- complexity of work;

- unsuitability for coloring;

- the need for thorough ventilation.

to contents ↑

Color palette

The color of the sealant is very important if you want to make the seams in the log structure invisible. You should choose a tool that is as close as possible in hue to the base material, given that the final tone will appear only after complete solidification. Sealant for logs can have the most varied colors under the tree:

- larch;

- wenge;

- Pine;

- oak;

- nut.

In many cases, neutral color compositions are suitable for work: white, black, gray. For the design of baths, gazebos, children's designs, you can use contrasting sealants, which will give the building a more stylish and elegant look. Some compositions sold in buckets can be tinted.

All acrylic and polyurethane products should be painted after drying, if necessary, by the user. Only bituminous materials are sold only in black, and it will not be possible to change it. Silicone sealants also do not paint, but their color scheme is quite rich.

to contents ↑The choice of sealant for a wooden house

You should not use conventional means for sealing joints in a wooden structure, here you need a special sealant. The quality and service life of the joints depends on the selection of a suitable composition. For new log cabins, you should buy products with maximum elasticity, because fresh wood is subject to severe deformation. For old buildings and houses from glued beams, less plastic compositions are suitable, since such materials shrink less and do not suffer from cracking.

When buying a sealant, one should take into account the remaining shelf life: if it already expires, the composition loses its adhesion and a number of other properties. The funds in the buckets may deteriorate if during storage the lid was slightly ajar or the container was damaged.

to contents ↑When you have to apply sealant in the cold season, you need to make sure that it is possible and carefully read the manufacturer's instructions.

Sealing technology for interventional seams

Usually, the joint is closed several months after the construction of the house, in order to immediately eliminate the revealed construction defects and wait out the most severe shrinkage. This is best done in 1–1.5 years, which is not always possible. It is advisable to carry out external and internal sealing once, and it is worth working in the warm season.

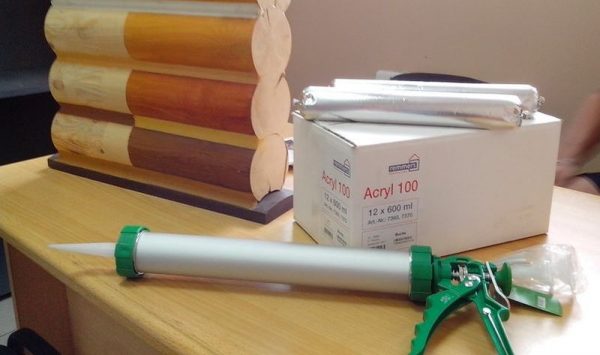

To work, you may need:

- water;

- rag;

- spatulas;

- masking tape;

- sealant;

- gun for sealant.

Surface preparation

If joints are sealed in a completely new house, then special preparation is not required. You can only wipe the joints with a damp cloth to brush off the dust, or vacuum them.

If the building has already been operated, more thorough processing must be done. They remove all the dirt, clean the seams from mold and fungus, apply an antiseptic. Grease stains are washed with a solvent until they are completely removed, then washed sequentially with soapy water and clean water.

Wooden walls in many buildings are treated with protective impregnations based on oils or solvents. They greatly impair adhesion to the sealant, so you will have to grind the base with a grinder with a special nozzle or manually with sandpaper. If water-based impregnation was used, wood polishing is not required.

After preparatory measures, evaluate the width of future seams. There should be no voids, other significant defects. If there are too large gaps, they are filled with an inter-crown heater. Most often, a cord-seal made of foamed polyethylene is used. It does not allow heat to pass, improves sound insulation, does not deteriorate from moisture. Such a cord seriously reduces the consumption of sealant and reduces the cost of work.

to contents ↑Sealant Application

In order to save, you cannot dilute the sealant with water - this worsens its quality. Due to the unpredictability of the effect, it is also impossible to combine compositions of different brands. A frozen product can be used, but you must first leave it at room temperature until completely defrosted.

If there is no experience in sealing joints, start with horizontal inter-crown joints, and only then process joints from the corners of the house. Act as follows:

- fill the tube into the gun, cut from the tip side at an angle of 45 degrees (hole diameter - 4-10 mm or more);

- the composition of the bucket is poured into a special reservoir of the gun;

- press the tip to the joint area, holding the gun parallel to the seam;

- squeeze the sealant, slowly moving the tip along the seam;

- fill the joint along the entire length, its thickness should be 5 mm or more;

- take a narrow spatula, moisten it with water, gently smooth the seam;

- if necessary, spray the seam with water from the spray gun, if it is more convenient to work in this way;

- excess composition is cleaned with rags, large accumulations of funds are cleaned with a spatula;

- process all the joints of the structure in a similar way.

In the first 3-4 days, it is extremely undesirable to get precipitation at the seams. After this time, complete polymerization will occur and the sealant will gain its final properties.

to contents ↑Cracking

First, a crack in the wood is cleaned of debris and dirt with a knife, and then it is blown to remove even the smallest particles of dust. Masking tape is glued on both sides of the defect perimeter - this will help the future seam to have even edges. In large cracks, push the cord-sealant with a spatula to a depth of 10 mm.

The sealant is inserted into the gun, a neat layer is applied along the entire length of the defect. Wet trowel level the tool, remove the excess. After immediately tear off the adhesive tape and leave the sealant to dry.

to contents ↑Wood Sealant Manufacturers Overview

The market presents products of domestic and foreign manufacturers. Most popular remedies:

- Perma-Chink. Acrylic compound suitable even for wide seams. It has high elasticity, does not deteriorate from UV radiation, water, temperature changes. Available in ten different shades.

- Energy-Seal. Made in the USA, suitable for clearances not exceeding 25 mm. It is resistant to fading, it is applied in any weather conditions.

- Remmers Acryl 100. Can close joints up to 50 mm in size, characterized by excellent adhesion, versatility, and a service life of up to 25 years.

- Wepost Wood. It has increased elasticity, withstands many cycles of compression and tension, tolerates severe temperature differences, fights against the settlement of mold and insects.

- Eurotex. Acrylic based sealant. It is used in any climate, reliably protects wood from all damaging factors.

Sealants for wood greatly facilitate the task of warming rooms and preventing premature destruction of structures. They optimize the microclimate in the building and have a lot of other useful properties, so they are used everywhere.