The need for installation or repair of glass arises quite often. Cracks, chips can occur anywhere - on doors, windows, greenhouses and many other products. Hard putties and other materials that do not have sufficient elasticity are not suitable. Here you need a special glass sealant - a high-quality tool that reliably fastens homogeneous and heterogeneous materials.

- Sealant purpose

- Features and Benefits

- Types of sealants

- Sealant Selection

- DIY sealing

- Glass Sealant Removal

- Materials and Tools

- Removing sealant from different surfaces

- From the tile

- From glass

- With plastic

- From skin of hands and clothes

Sealant purpose

Glass products are often called window products. The reason is that most often they are used precisely during installation, sealing and repair of window blocks. This helps reduce heat loss, fix cracks and prevent them from spreading. In addition, glass sealants are suitable for arranging and sealing:

- balconies, loggias, attics;

- counters, display cases, partitions and glass cabinets;

- greenhouses, hotbeds, glass roofs;

- advertising boxes, signs.

Many of these sealants are considered universal and, in addition to glass, are suitable for other materials - tiles, ceramics, polycarbonate, PVC, wood, metal. Using sealing compounds, it is possible to mount ventilation, air conditioning systems, cable channels, various fillet and expansion joints.

to contents ↑Features and Benefits

Glass sealants most often cure under the influence of atmospheric moisture, transforming into an elastic but durable mass. These materials, unique in their properties, are made on the basis of rubber (silicone) or various polymers using modern technologies. After application to the glass, a structure resistant to moisture is formed, which is difficult to damage mechanically.

Most glass sealants are not afraid of ultraviolet radiation, so they are suitable for indoor and outdoor use. They do not deteriorate from temperature extremes, the influence of aggressive chemicals, and can work in heat or at temperatures below minus.

The advantages of sealants are:

- Reliability. The degree of adhesion of the products with glass is high, sometimes even priming is not required. The finished seam will be durable, airtight, will not let moisture, dust, and dirt pass.

- Elasticity. Sealants have a special structure, therefore they are able to adapt to vibrations, vibration, narrowing and expansion of materials. Seams are not destroyed by the action of damaging factors, are not covered by cracks, serve for several years.

- Chemical inertness. Sealants do not contain substances that are capable of reacting with the base material. This helps protect the surface from damage, creates a durable film.

- Unique mode of operation. In various situations, the glass may be heated or sharply cooled. The sealant can withstand freezing up to –40 degrees or warming up to +180 degrees or more.

Types of sealants

Different compositions are sold in stores that are suitable for working with glass products:

- AcrylicThey are used instead of the old putty for window frames, providing reliable adhesion to most building materials. Acrylic sealants are suitable as insulation, frost-resistant, but have medium elasticity. After hardening, acrylic can be plastered, painted. Sealants are suitable for internal work, because they do not emit harmful, toxic components, and also have fire-fighting properties. With strong humidity in the house, it is better not to apply acrylic compounds - they are quite porous, so they will absorb water from the air, from which the seam may darken or begin to crumble. It is possible to eliminate this minus by staining the seam with protective coatings.

- Silicone It is such products that are considered the most popular as glass sealants. They are acidic and neutral. The first are made on the basis of acids, so they can spoil the metal in contact with it. Neutral sealants are more expensive, but do not provoke corrosion, have a high degree of adhesion and are able to connect even dissimilar materials, for example, glass with wood, iron. Silicone sealants are suitable for exterior and interior use. They are very elastic, they are not destroyed by vibration and temperature changes caused by compression and expansion of materials. The products have an optimal consistency and easily penetrate even the smallest crevices and cracks. The disadvantage of silicone is its poor staining, as well as damage from the application of certain types of paints, plasters.

- Polyurethane Such sealants are not afraid of contact even with aggressive chemicals, ultraviolet, and can withstand temperature extremes. The elasticity of polyurethane is very high, it dries quickly, stains well, is hydrophobic and does not absorb moisture from the air at all. Due to the presence of solvents, polyurethane sealants are best used only for outdoor applications.

- Polysulfide (thiocol). Such compositions guarantee reliable bonding of parts, strong sealing, their work does not depend on temperature, humidity, the action of aggressive substances, ultraviolet radiation. Sealants retain their properties in snow, rain, frost, without losing integrity. Minus - the presence of organic solvents in the composition.

- Sealants based on MS polymers. Products with this composition are often called "liquid plastic." Despite their perfect compatibility with various types of plastics, sealants are excellent for working with glass surfaces. They have a high degree of adhesion to building materials, are very durable, but have medium elasticity, therefore they are not recommended for deformable substrates. MS-polymers retain their strength even at -55 degrees, are completely not afraid of ultraviolet radiation, aggressive liquids and vapors.

There are sealants on a cyanoacrylate basis, which in their properties remind everyone of the well-known superglue. They instantly dry, are absolutely transparent, quickly seal and seal any seams, defects. Such compositions have low elasticity, and they can only be used on substrates that are not subject to vibration, vibration, displacement. As for the form of release of sealants, it can also be different. Most often on sale there are standard tubes, plastic buckets and cans, tubes and cartridges, sprays.

to contents ↑Sealant Selection

For sealing large joints and cracks between the wall and the window, polymeric polyurethane foam is traditionally used. If the gap is of moderate size, it is preferable to use a glass sealant. When selecting funds for double-glazed windows or other purposes, you need to be guided by the features of the work.

Acrylic sealants are suitable for repairing old wooden windows. Due to their water resistance, vapor barrier capabilities, resistance to cold and good adhesion, they will completely replace putty. Sealants based on polyurethane or MS-polymers are indispensable for secondary sealing of the edges of a glass packet, which is carried out during assembly of blocks. The use of sealant creates an additional hard, durable contour that helps withstand external damage.The same types of tools are widely used to connect glass with metal, for example, when installing domes.

Silicone compounds are ideal for sealing various defects, sealing cracks, including for internal work. They become a reliable barrier between the atmosphere and the room, help to wait time before the overhaul of the windows.

to contents ↑DIY sealing

To work with glass sealant, you need to purchase a suitable mounting gun. It allows you to make seams even, reduces material consumption, simplifies the sealing of joints. You also need to buy a narrow spatula for leveling the composition and a small paint brush. You will also need paper tape to protect the surrounding surfaces and align the seam. It’s worth working at temperatures not lower than +5 and not higher than +40 degrees.

First, thoroughly clean the surfaces, remove stains of fat from them (for this purpose water and detergents, degreasers may be required). After allowing the products to dry, if necessary, the contact base is primed. Masking tape is glued along the gap.

The sealant is applied evenly on the joint of the surfaces. Pre-install the tube with the cut tip into the mounting gun. After that, the completed seam is immediately leveled with a spatula or brush moistened with water. Excess sealant is removed with a spatula, masking tape is torn off even before the composition hardens. All remaining irregularities are carefully smoothed with a brush or soft sponge.

to contents ↑Glass Sealant Removal

If the glass sealant is dry, it will be quite difficult to remove its stains - you will have to make serious efforts.

Materials and Tools

A sharp knife is good for mechanically removing drips. They carefully, without rushing, cut off the layers of sealant, trying not to scratch the base. You can use a screwdriver, pumice, but on delicate surfaces such methods are better not to use. Abrasive cleaning or cutting stains are more suitable for inconspicuous areas.

For safer cleaning, you can purchase a special scraper for glass made of plastic, wood. In appearance, it resembles an ordinary spatula, but has a pointed tip slightly thicker than that of a knife. Using a scraper, you can easily scrape off traces of silicone or other sealant. In the absence of such a device, a kitchen scraper for pans is used.

to contents ↑Also, wire washcloths are used to clean the bases from the sealant. They can remove excess sealant in the bathroom, in the kitchen. Still for work napkins or rags which are necessary for the final cleaning are useful.

Removing sealant from different surfaces

Depending on the type of substrate, the cleaning methods used may vary. It is worth using only those methods that will not damage the main material.

From the tile

It is necessary to clean the tiles from traces of sealant quite often, especially if the work was carried out at an accelerated pace or partial repair of the coating was carried out. When the product has not yet dried, you can wash its stains with a normal soap solution and a soft kitchen sponge. For this purpose, household, toilet or liquid soap is suitable.

Other methods for removing sealant from the tiles are as follows:

- Vinegar. Acid is able to soften silicone or other substances in the composition of sealants, but only in sufficient concentration. For work use vinegar essence in its pure form or slightly diluted with water. They work only in tight rubber gloves, otherwise there is a risk of a chemical burn! Apply the liquid to the stain, leave it to loosen its structure, then clean it with a knife or scraper.

- Acetone or white spirit. Solvents can be used to clean the tiles, but proceed with caution.Some types of tiles can become matte, especially glossy and brightly colored! The napkin is moistened in a solvent, applied to the place of the defect, and after a minute the sealant is wiped with a cloth. After necessarily washed tile soapy water. Instead of these solvents, gasoline or kerosene can be used.

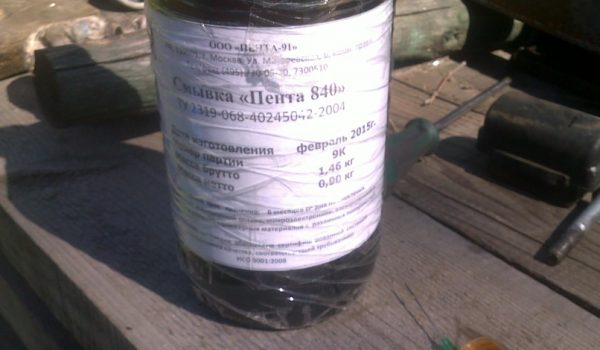

- Penta-840. This is a special tool for removing various construction contaminants. If you plan to repair using sealant, it is worthwhile to buy liquid in advance in order to easily get rid of sagging, stains and excess. Flushing is implemented in any construction supermarket, its price is quite low, and its efficiency is high.

From glass

Glass traces can be cleaned with sealants using an ordinary knife. The procedure is carried out carefully, otherwise scratches may remain on the surface. If the sealant cannot be completely cut off, its residues must be dissolved with vinegar, white spirit. Gasoline and other petroleum products should not be used - rainbow stains will appear on the product.

to contents ↑With plastic

The easiest way is to remove the silicone sealant from the plastic, which is not too firmly attached to this material. If you can’t remove it completely, use the Dow Corning OS-2 tool, which qualitatively cleans the plastic without harm to it. The solvent is applied to the stain, after half an hour the jelly-like mass is removed with a spatula. Traces of sealant are wiped off with a rag. When greasy marks remain on the plastic, they are washed with a dishwashing detergent.

to contents ↑From skin of hands and clothes

Sometimes glass sealant gets on clothes. It is necessary to act quickly in this situation, otherwise the adhesive components are absorbed into the fabric. To get rid of pollution, you can use one of these methods:

- stretch the fabric, pick up the sealant stain with a construction spatula and remove it;

- put clothes in the freezer for 2-3 hours, then crumble the remains of the sealant manually;

- add a little vinegar or technical alcohol to the item, then wash the defect or brush it.

To clean the sealant from your hands, you need to steam them in hot water, rub with ordinary salt. Due to the abrasive properties, the product will surely remove dirt residues from the skin. You can also use a body scrub, pumice, hard washcloth, after washing your hands well. If you work with gloves and old clothes, you will be able to avoid such problems: all issues regarding product sealing will be resolved safely and comfortably!