In order for the indoor microclimate to be optimal, high-quality sealing of interpanel seams is required. This event will help reduce the risk of leaks and exposure to atmospheric factors. If the integrity of the joints is broken, the reaction should be quick: you need to immediately close the cracks and destruction zones in the right way, otherwise you can not avoid the settlement of the fungus and freezing of the walls.

- Why process seams in a panel house

- Technology for repair of interpanel seams

- Primary sealing of the external seam

- Secondary termination of the external interpanel joint

- Repair without opening the joint

- Partial opening

- Technology of warming "Warm seam"

- Sealing the seams inside

- Rules for sealing interpanel seams

- What materials can be used

- How to repair the seams in the house on your own

- Training

- Warming

- Sealant Application

- Topcoat application

- Masters Tips

Why process seams in a panel house

Sealing joints in a panel house is an important stage in the construction of buildings. It involves the process of filling the voids that are between vertical and horizontal plates. Also, sealing must be done in the future, especially when the apartment building is old, because the seams are gradually damaged, lose their integrity and require restoration.

If this procedure is not carried out, moisture and air will begin to get into the area of the tile joints, and condensation will form. This will lead to freezing of the walls and the colonization of harmful microorganisms. In addition to dampness and mold, the rooms will have a lower temperature. Sometimes the percentage of heat loss for this reason reaches very impressive values. There is also an aesthetic component in the need to seal the joints between the plates: wallpapers on cold walls do not hold well, inevitably peel off, the plaster turns black, which looks very ugly.

Depressurization of the facade can happen at any moment of the "life" of the house. Its cause can be:

- improper building design, deviations from SNiP;

- the displacement of the panel blocks due to the uneven shrinkage of the supporting structures;

- deformation of blocks from strong temperature extremes, intense precipitation;

- violations at the stage of construction work;

- the use of low-quality materials;

- a combination of materials with varying degrees of elasticity;

- excessive tension of self-adhesive sealing tapes.

Technology for repair of interpanel seams

Warming of interpanel spaces is carried out in several stages according to a certain technology. The appearance of deformation changes forces opening the grooves between the panels and carefully inspecting them. If the house is still under warranty, all repairs are carried out by the developer. Old buildings are usually processed with the assistance of third-party specialists in the field of industrial mountaineering.

Climbers services are required for repairing external joints at high altitudes (3-4 floors and above). Independent work is practiced at the level of the first or second floor with reliable forests. The technological stages of sealing wall seams are as follows:

- Training. All surfaces are cleaned of dust, dirt, paint residues. The seams between the panels are embroidered.

- Foaming.Seams are filled with polyurethane foam - a reliable heat-insulating material that, after curing, expands and fills even small voids.

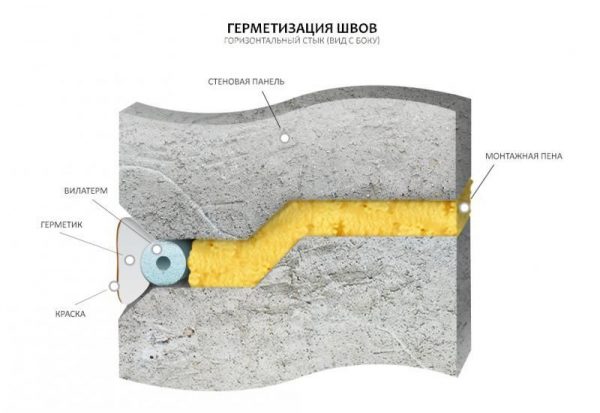

- Warming. Street seams are covered with the selected insulation (usually of the Vilaterm type).

- Final processing. Mastic sealant is applied, which will protect the insulation from external influences.

All work on the processing of seams outside buildings is carried out at -10 ... + 30 degrees and only in dry weather. If you neglect this rule, the sealing layer will not last long. Sometimes, if repair from the outside of the house is impossible, the seams must be insulated from the inside of the apartments. In this case, the grooves are foamed and sealed with insulation, and then sealant. With a satisfactory condition of the sealing material can be limited to incomplete cleaning of the seam and only foaming.

to contents ↑Primary sealing of the external seam

Primary sealing involves the processing of interpanel seams in new homes. Most often, the same “Vilaterm” is used in the form of polyethylene foam tubes. It is characterized by high elasticity, good thermal insulation properties, and is easy to install. Also, instead of this material, mounting foam can be used, but in any case, the mastic should act as the top layer, which acts as a waterproofing agent for the home.

to contents ↑Secondary termination of the external interpanel joint

Secondary sealing is understood to mean repair of internal or external joints that have lost integrity and strength during the operation of the building. The only difference in technology is to perform additional cleaning of the joints from the remnants of insulation material. It is recommended to evaluate the condition of the joints every 5-7 years and repair them in a timely manner.

to contents ↑Repair without opening the joint

This option is possible only with a satisfactory condition of the surface of the seam, so to begin with it must be carefully inspected. The top layer - mastic - still have to be removed. It happens that there is a cement composition inside, in which case the joint most often maintains its integrity. Seam sealing actions will be as follows:

- treat with a deep penetration primer with antifungal components;

- close holes, chips, any defects of the base with a cement mortar;

- apply a layer of waterproof mastic (one- or two-component), after covering the front edges of the panels with a strong adhesive tape.

Partial opening

This repair method is used if the seal is partially destroyed or the outer joint coating has lost strength. Compared to cosmetic measures, this method is more reliable. The sequence of work is as follows:

- remove the destroyed parts of the cement composition, in the rest of the layer, drill holes every 25 cm (use a drill of 10 mm);

- fill empty areas with foam;

- wait for the foam to dry, cut off the protruding parts;

- apply a primer, allow to dry;

- plaster seams, dry;

- to process with bituminous mastic.

Technology of warming "Warm seam"

The application of this technique will allow you to insulate the walls most reliably and efficiently. It is considered to be three-component and rather complex, requires more time than simple cosmetic repairs. First, the preparation of the seam is carried out, then the main work:

- the joint is opened completely, along the entire length;

- even small pieces of old insulation, cement, foam are removed;

- if required, a cement restoration of the coating inside the seam is carried out (when the panels themselves become damaged);

- priming with deep penetration;

- the space is filled with polyurethane polyurethane foam approximately ¼ of the gap volume (the material will expand greatly subsequently);

- immediately after the start of the process of increasing the mounting foam in butt size, the foamed polyethylene is laid in the form of a bundle of the desired width (this eliminates the need for cutting foam).

The insulation is installed using a spatula - the material is gently pressed into the foam.It is desirable that the strip was continuous, without tearing, about 10% more in width than the seam itself. It is necessary to work with foamed polyethylene carefully, it is easily damaged. After finishing the arrangement of warm seams, you need to evaluate the result: the borders of the plates should be on the same level with the sealed joint. Next, bitumen mastic is applied, which will prevent moisture from entering the joint.

to contents ↑Sealing the seams inside

Often, cold air begins to penetrate into the housing from the side of the walls on the balcony, loggia, freezing areas in the rooms. In this case, it is possible to seal the joints from the inside, although this measure is considered temporary, and in the warm season you still have to carry out the sealing using standard technology outside the house. Otherwise, moisture will accumulate in the cracks and destroy the internal sealing layer, even the most reliable.

To make joints more airtight, work is planned in a similar way. Wallpaper or other coating must be removed. Then the gap is cleaned, primed and sealed with foam or covered with cement plaster. At the end of the work, the joint is covered with waterproof mastic. Unfortunately, after such a repair, the dew point from the middle of the panel shifts to the inside of the wall. This causes condensation to drain off and destroy the adjacent area of the floor covering. As soon as the street gets warm, you will have to once again clean the joint and do all the work again and already turnkey (outside).

to contents ↑Rules for sealing interpanel seams

Exact adherence to technology is a guarantee of a high-quality result. There are a number of rules that must be followed when sealing joints:

- if leaks appeared in the area of the end sections of the wall, overhaul is required (it should cover the seam of the end and adjacent sections of the walls);

- when the problem concerns a vertical joint, a complete cleaning and sealing of the seam with adjacent horizontal zones along the entire height of the facade is performed;

- violation of the strength of the horizontal interpanel joint necessitates the repair of 3-4 rows of plates.

It is equally important to choose the right materials for repair work, because the seams between the panels carry a rather large load, constantly undergo tension and compression from temperature extremes.

to contents ↑

What materials can be used

When insulating walls or roofs, it is necessary to choose those means that, in terms of composition and properties, correspond to operating conditions, are sufficiently resistant to loads, are not subject to significant shrinkage, and are elastic. Since the main purpose of the materials is to seal the joints and waterproof them, any of them should provide reliable protection against moisture, be waterproof.

To repair interpanel seams, the following types of tools are used:

- mastics and sealants;

- waterproofing harnesses and strips;

- mounting foams;

- ready-made foam insulation;

- cement compounds.

What specific material is suitable depends on the features of the repair. So, for cosmetic updates, cementing joints and coating with bituminous mastic may suffice. For overhaul, it is worth using mounting foam in isolation or in combination with Wilaterm insulation. In any case, the top layer should be a high-quality hydrophobic coating - mastic and sealant. For repair, such tools have proven themselves well:

- "TekhnoNIKOL 2K" - polyurethane sealant for interpanel seams;

- "Espogerm 1" - hybrid front sealant;

- "Accent 117" - acrylic sealant for joints in concrete;

- "Hermes 17" - means for interpanel seams;

- “Tektor 201” - sealing mastic;

- "Magir" is a suture mastic.

How to repair the seams in the house on your own

If you wish, you can seal the walls without the involvement of specialists. Of course, we are not talking about work at heights, here the repair must be entrusted to professionals. Most often, self-internal insulation of the joints is carried out on an emergency basis, when they were not ready for the winter season, or sealing the outer walls on 1-2 floors.

Training

First you need to purchase mastic, foam, insulation (depending on the chosen work option), calculating their number by linear or square meters. Also required:

- putty knife;

- sandpaper;

- metal brush;

- vacuum cleaner;

- sponge and water;

- broom;

- solvent.

All furniture and things are taken out of the room so that the room is empty. The old coating is completely removed from the walls and from the seam using any improvised means: spatulas, brushes, etc. Before the start of the main stage, the joint must be clean, for which it must be vacuumed or washed, and then it must be thoroughly dried and treated with a solvent for degreasing.

to contents ↑Warming

It is desirable to fill a large interpanel gap with mounting foam, and lay a layer of thermal insulation on it in the form of a solid hollow tube (using the “warm seam” technology). There is an option to first put the insulation, and then foam it. Excess foam after drying is cut off, leaving a place under the mastic.

Sealant Application

The sealant is applied gently, in a continuous line, over the entire length of the seam. Some compounds are more convenient to apply with a spatula, others with a construction gun. Excess mastic or sealant is removed immediately with a wet sponge, otherwise the composition will then solidify tightly.

to contents ↑Topcoat application

Many experts advise after the mastic to perform another coating layer, which will be decorative. Typically, cement-sand mortar (plaster) is used for this purpose, suitable for outdoor use.

to contents ↑If for some reason the layer turns out to be thick, it is better to put a mesh in the base, otherwise the cement may crack quickly. After drying, the topcoat can be painted with frost-resistant paints.

Masters Tips

In old houses, apartments there are almost always plots infected with mold. To get rid of it, before sealing it is recommended to conduct an anti-mold treatment of the outbreak. A more effective result will be upon further drying of the walls with a heat gun.

In addition to sealing interpanel joints, it is worth paying attention to other sources of heat loss: old glass windows, poor-quality doors, an uninsulated roof, an uninsulated attic (in a private house). Up to 20% of heat can be lost through such zones, and additional sealing of windows and doors, as well as interpanel seams, will seriously improve the indoor climate and make living more comfortable!