When carrying out repairs in a house or apartment, you can use a special material - an OSB plate. Such slabs easily hide surface defects, they practice different types of finishes.

- OSB-plate and its characteristics

- OSB for wall covering

- Plate processing without putty

- Liquid wallpaper

- Ordinary wallpaper

- Method of working with OSB with surface preparation

- Grinding

- Padding

- Joint sealing

- Reinforcement and protective corners

- Puttying

- Glue selection

- Wallpapering

It is most popular to wallpaper material - such work is not difficult at home. How to paste wallpaper on an OSB-plate, properly process it and give a beautiful look - we will consider all issues in detail.

OSB-plate and its characteristics

The real name of the material with the familiar sound of an OSB plate is actually different - OSB, or oriented strand board. Nevertheless, the English "oriented strand board" gave the abbreviation OSB, which is used in the construction industry much more often. Other names of the material can be seen by an order of magnitude less often - USB, USBI.

OSB plate is widely used in finishing and repair work, mainly for processing walls, but can also be used for mounting on ceilings, floors, to create partitions. The structure of the plate is multilayer, each layer consists of wood chips, coniferous wood chips. They are laid in one direction and pressed, connecting with the help of special adhesives, resins, paraffin. After polymerization, an even glossy surface is formed. OSB has a number of useful properties:

- good thermal insulation (due to low thermal conductivity);

- moisture resistance, protection against moisture of internal materials;

- high strength, rigidity, elasticity;

- the ability to hold any fasteners;

- convenience in further decoration;

- a small number or complete absence of defects;

- environmentally friendly composition;

- profitability (made from waste, has a low price).

to contents ↑According to their moisture resistance and plate thickness, they are divided into 4 types - OSB 1, 2, 3, 4. The lower the number, the less water resistance the material has. Also, when buying, you need to pay attention to the environmental safety class (E0, E1). If the plate indicates E0 or "ECO", it can be used without finishing. E1 boards must be treated before use and other materials glued to the surface.

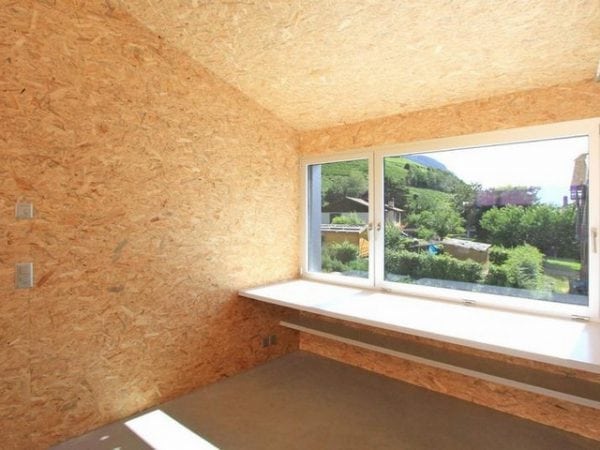

OSB for wall covering

There are two options for pasting OSB boards with wallpaper. In the first case, the option without preparation is used - without puttying. At first glance, this method seems simple - the material is dense, even, gluing wallpaper to it will not be difficult. But this method threatens with negative consequences - the wallpaper may begin to bubble. In general, not all plates are suitable for wallpapering:

- OSB 1 - are used only for the assembly of temporary layouts, packaging of goods, are not used in the repair of premises;

- OSB 2 - their thickness is greater (about 2.5 cm), but due to the instability to the action of water, plates are used only in dry rooms;

- OSB 3 - most often bought for decoration of houses and other premises, they are thick, you can glue wallpaper on them without problems;

- OSB - impervious to water, used mainly by professionals for the construction of removable formwork, are expensive.

To sticker the wallpaper, you should immediately purchase the right material, and then choose the appropriate method of decoration.

to contents ↑Plate processing without putty

Sticking wallpaper without putty seems to be a simple solution. But you need to remember that the OSB is created with the preservation of the gaps that are necessary for the movement of the material when expanding or narrowing. Such a technical feature can provide a bad service - if you do not close the seams, wrinkles will appear later. Therefore, even without putty, it is necessary to coat the joints with a silicone-based sealant.

Wallpapering without putty should also take into account the type of finishing material. If the wallpaper is thin, they will not be able to cover all the roughness of the plate. In this case, you can not do without preliminary grinding with a grinding machine.

So is it possible to glue the wallpaper in a "simple" way? The disadvantages of this method are as follows:

- the relief of the plate after applying glue will be clearly visible under the wallpaper;

- through light thin wallpaper the structure of the tree will shine through;

- resin, paraffin, impregnation appear through the wallpaper paper after the temperature rises in the room;

- the adhesion of the surface to the wallpaper as the impregnation is highlighted will deteriorate;

- if the environmental friendliness of the slab is low, the wallpaper without a different finish will not fulfill its protective function.

Thus, high quality finishes can only be achieved with full technology. Only in a number of cases is a “simple” way possible. For example, when gluing vinyl, non-woven wallpaper with a large thickness or large relief. If such a material has a light color, you must first paint the OSB with white paint - this isolates the coating. Also, without puttying, you can apply liquid wallpaper - they themselves will hide all defects.

to contents ↑Liquid wallpaper

Before applying this coating, the plate should be primed and all joints must be sealed with sealant. For this purpose, only E0 grade boards are used.. With high-quality preparation and priming, liquid wallpaper after solidification reliably adheres to the stove, which will prevent leakage of impregnation and will allow you to get a beautiful decor.

Ordinary wallpaper

As already noted, only thick and embossed wallpapers can be glued without puttying. Soil application is required in any case - this will prepare the panels and improve adhesion. Be sure to use plates E0. Before gluing light materials, paint with insulating properties is used.

Method of working with OSB with surface preparation

The right way to get a quality finish involves carrying out successive stages of work. This is grinding, primary primer, processing joints, gluing reinforcing mesh. Then putty is applied, the surface is primed again. Then you can begin to glue the finishing material. To complete the process, brushes, rollers, containers, spatulas are required. You also need to buy wallpaper, putty and primer, reinforcing mesh, wallpaper glue.

to contents ↑Grinding

Finishing work begins with grinding the panels, for this, sandpaper is used. With its help, all irregularities and wood pile will be removed, and the protruding resin will be eliminated. The latter, together with paraffin impregnation, makes adhesion of surfaces poor, so this step cannot be ignored.

Padding

The primer can seriously improve the quality of the finished coating. It creates a waterproof film that will prevent the OSB panel from swelling from contact with moisture, glue. Also, the primer will smooth the relief of the slab so that it does not appear on the surface. If primary priming is performed, the resins and impregnation will not protrude from the base material, and the adhesion strength with wallpaper will increase.

It is best to purchase a special composition for OSB-plates. Also suitable is latex or acrylic primer, which have antiseptic components in the composition.An affordable option is to dilute the PVA glue with water 1: 3. A ready-made primer purchased at the store is applied to a 2-layer board, made of PVA - to 3 layers. After each layer, the surface is allowed to dry completely, which generally takes 2-3 days. After priming, they are painted with white interior paint using a roller. This step is omitted if puttying is used.

to contents ↑Joint sealing

When fixing the panels, seams between them are inevitably obtained, the holes remain during the fastening of the plates. Chips will also have to be repaired, if any. As soon as the soil has dried up, you need to begin to eliminate such defects. For this purpose, construction foam, glue, silicone-based sealant are used. If the cracks are large, they are foamed or sealed with putty. The fastener heads are also lubricated with a sealant so that rust does not appear further in these places. Another option is to coat the fasteners with oil paint.

to contents ↑Reinforcement and protective corners

The ideal option is to glue the entire surface of the OSB with a serpentine (reinforcing mesh), but in the absence of such an opportunity, only the joints of the plates can be glued. Gluing should start from the slope, while making sure that the joints do not fall at the corners. The grid is glued with glue, and also pass along it with a construction stapler after 10 cm. This material performs the following functions:

- reduced risk of coating cracking;

- the exclusion of cracks, defects that may occur during shrinkage of the plate;

- simplification of puttying;

- improved adhesion of the base with wallpaper.

Protective plastering or painting corners are installed on the outer corners of the surfaces, putting them on glue.

to contents ↑Puttying

For high-quality leveling of the surface, fiberglass (repair non-woven) is sometimes used, in which case you can not even use a sickle. But professionals recommend using putty, which will give perfect alignment of the wall. How to putty surfaces? For this purpose, elastic compositions based on acrylic, oil-based, which are suitable for wood, are used. A simple putty for concrete will not work, it will quickly peel off. The procedure is as follows:

- stir the product with a mixer to exclude lumps;

- take a little mass on the spatula, apply a thin layer on the base, smooth;

- alignment is done until the surface relief is completely eliminated;

- after drying the putty, wipe the joints with a grater, fine sandpaper;

- brush the wall with dust residues;

- to finish the work, perform another primer coat and wait a day;

- Then you can glue the wallpaper.

Glue selection

There are many brands and types of adhesives on sale, it is best to purchase professional products. For paper wallpaper, the CMC tool is suitable - glue for wallpaper. If you decide to glue vinyl material on a non-woven basis, you can buy glue “Lacra for non-woven wallpaper”, “Methylane Vinyl Premium with indicator”. For fiberglass suitable “Methylane Fiberglass Premium”, “Methylane Granulate Premium”.

to contents ↑Wallpapering

The order of gluing the finishing material does not differ from that for the usual process of stickering wallpaper on a wall of drywall, concrete. It is necessary to choose the right material, cut it into strips of a suitable size. If the wallpaper is patterned, it is customized exactly. Glue is bred according to the instructions, applied to a wall or wallpaper (depending on the type of material) at a fast pace. Then proceed to pasting the walls from the window. It is necessary to avoid getting glue on the front of the wallpaper, so that there are no streaks and stains.

After gluing the strip, it is necessary to iron it, removing the accumulated air. The joints are rolled with a rubber roller, the glue that has come out is washed with a soft cloth.On smooth OSB-plates, the wallpaper looks very beautiful, the main thing is not to neglect the technique of the process and not to shorten the stages of work.