Polyurethane adhesive has many advantages compared to PVA and other types of popular formulations. It differs from them in technical characteristics, properties and methods of application. You can use this glue for wood, metal, it also fits a number of other materials.

- Features and advantages of polyurethane adhesive

- Scope of adhesives

- Composition and properties

- Types of polyurethane adhesives

- One component formulations

- Two-component adhesives

- Application and Safety Rules

- Than to dilute and wash glue - means

- Solidification time

- Storage Features

- Adhesive Manufacturers

Features and advantages of polyurethane adhesive

Polyurethane adhesive is an adhesive based on solid synthetic resins. The number of such resins is the main difference between this glue and analogues: these components are up to 95%, while in the other glues it is much less. Polyurethane adhesive has a special curing principle: a chemical reaction begins after the interaction of the composition with water vapor. As a result, bubbles of carbon dioxide are released, and the glue layer turns into a strong film.

The appearance and behavior of the adhesive resemble those of polyurethane foam. After applying the adhesive with a thin layer, it gradually expands, the excess creeps out of the seam. As it hardens completely, it can be carefully cut with a knife, a chisel. This composition has a lot of advantages:

- Strong bonding of homogeneous and dissimilar materials. Thanks to rigid and reliable bonds, polyurethane-based products tightly fasten wood, plastic, metal and many other materials. It can be used on raw or antiseptic treated wood - this will only speed up curing.

- Water resistance. Polyurethane compounds are indispensable in high humidity, as well as in contact with water. They do not deteriorate from such conditions, because the adhesive joint will be moisture resistant and can serve as a sealant.

- Sufficient open exposure time. Even a beginner can work with polyurethane. The glue does not harden for 20 minutes, and during this period you can calmly adjust the details, install the clips. For a reliable connection, you need to fix the product for 1 hour, although full use is allowed only after a day.

- Simplicity of work. Thanks to convenient application, easy gliding of the composition, it is not difficult to use.

- No harm to materials. The glue does not oversaturated porous substrates with moisture, does not cause a risk of warpage. Thanks to this, it can be used even for laying parquet without the danger of swelling dies.

to contents ↑Polyurethane adhesives are resistant to temperature extremes, freezing and heating. They are chemically resistant to gasoline, oils, aggressive compounds. Do not glue only silicone, polyethylene and polypropylene with polyurethane, since the adhesion quality will be poor.

Scope of adhesives

Due to their versatility, polyurethane adhesives are used in completely different areas of life. They are suitable for natural and synthetic materials: fabrics, plastic, rubber, glass, polystyrene, ceramics, they will not spoil even cardboard and paper. Since adhesives are not afraid of frost and precipitation, they are successfully used for outdoor work. Here are the areas of application of polyurethane:

- gluing finishes - ceramic and stone tiles, marble, mosaics, porcelain tiles;

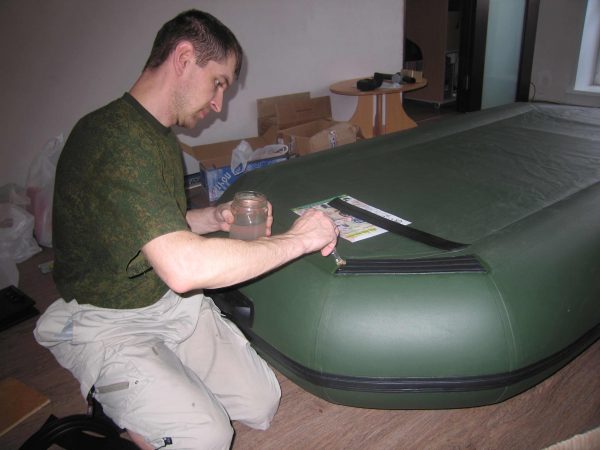

- sealing defects in inflatable products - boats, pools, children's toys;

- fixing window profiles, PVC edges on furniture, panels;

- bonding the base with stone chips in the production of flexible stone;

- the attachment of artificial grass, rubber mats in stadiums and venues, in gyms;

- production of sandwich panels;

- joining of eaves, baguettes, plinths, stucco moldings, wooden beams and plastic elements;

- repair of products from glass, porcelain, ceramics, plexiglas in everyday life;

- restoration of furniture and interior items;

- shoe repair - gluing heels, soles, insoles;

- laying of floor, panels, blocks, closing up cracks, arrangement of thermal insulation systems and warm floors;

- Application as a car sealant, to protect parts from corrosion.

Composition and properties

At the heart of polyurethane adhesives are urethane rubbers of different quality and production, differing from each other:

- properties that appear after the final polymerization;

- the structure of the adhesive layer, which may be linear or mesh;

- solubility in organic solvents.

The main raw materials are most often produced by foreign manufacturers (domestic share is only 10%). The composition of polyurethane adhesives also includes additional components (more than 10-15 items), which determine the final properties and quality of the product. Depending on the specific set and amount of these substances, viscosity, adhesion of the adhesive, its curing rate, the dependence of indicators on humidity and temperature, and shelf life can vary. Among the additives to polyurethane, the following should be indicated:

- zinc oxide, titanium dioxide, soot, Portland cement;

- hydroxyls and isocyanates;

- acetone, alcohols and organic solvents;

- artificial and aromatic resins, surfactants;

- aqueous emulsions, alkaline solutions of salts, acids;

- crystallization stabilizers and accelerators.

Dyes and pigments, usually based on metal oxides, give a different shade to the finished mixture. Amber or brown adhesives are bought for woodwork, gray or black for metal. Also on sale are white, yellow and colored compounds. By consistency, they are liquid, pasty, gel.

Due to the different composition, the properties of adhesives vary widely. For example, the flow rate with uniform continuous application to the surface can be 500-1000 g / sq. m, and with a point - about 100-150 g.

The finished coating can be operated at temperatures of -40 ... + 120 degrees. Better adhesion is observed when joining porous, rough surfaces, although smooth materials are also subject to bonding.

Other features of polyurethane compounds:

- work with adhesives is allowed only at positive temperatures - from +15 degrees, otherwise their curing will slow down, and the properties of the finished seam may change;

- the adhesive has thixotropy (increases viscosity at rest, liquefies under mechanical stress), so before the start of operation, you need to wait until the moment of complete cure;

- polyurethane prevents the spread of fungus and mold due to antiseptic properties.

Types of polyurethane adhesives

Depending on the number of compositions with components, adhesives based on polyurethane can be one-component and two-component.

One component formulations

Most often, in household, for gluing wood, repairing shoes, equipment, one-component glue is used. It is ready for use, as in one bottle are the main composition and hardener. For polymerization, the product requires moisture, which is contained in the air or in the material itself. If the air humidity is less than 60%, it is recommended to lightly moisten the base. After the foaming begins, the adhesive joint increases in volume, which must be taken into account when planning its thickness.

to contents ↑Two-component adhesives

The two-component composition is represented by 2 packages, which must be opened before work, and the contents mixed with each other. Such actions are performed immediately before the bonding of the products, otherwise a portion of the glue will quickly deteriorate. It is important to strictly observe the proportions when connecting the components or the chemical reaction will not start. Humidity does not play a role for such adhesives, their polymerization proceeds under the influence of the hardener from the second bottle, and therefore the means are used to glue moisture-proof substrates (glass, metal). For quick drying, the adhesive joint can be treated with hot temperatures (+ 100 ... + 110 degrees).

to contents ↑Application and Safety Rules

If you are working with wood with a moisture content of less than 8%, both surfaces are sprayed with water, allow the liquid to absorb, and only then proceed to gluing. Before this, other preparation measures must be taken: they remove dirt, garbage, dust, fats and other pollutants. Also clean the base of cement, plaster, paint. For degreasing, wipe with alcohol, solvent.

Glue is applied in a thin layer over the entire surface. This is especially convenient if the adhesive has an aerosol form. Thick pastes, viscous solutions are applied and distributed with a spatula. Two-component adhesives are first mixed according to the instructions, then they perform similar actions. The rules for working with polyurethane are as follows:

- the amount of glue should be small, otherwise the expanded layer will turn out to be too thick;

- complex substrates are covered on both sides to be glued, others on only one;

- porous surfaces are treated with glue in 2 layers, the second is applied 2-3 minutes after the first;

- aerosol adhesives are sprayed with uniform strips every 10 cm, 8 cm from the edge;

- after application, the product is allowed to dry for 5-10 minutes and only then the parts are fixed with strong pressure on them (if possible, the product is rolled with a roller);

- elements of the product after tight fitting are fixed with a clamp, leave it for 1.5 hours;

- after the polyurethane has dried, the remaining foam remains are carefully scraped off with a chisel;

- You can use the product in a day.

So that the remaining glue does not deteriorate, the bottle must be squeezed to release air, then immediately tighten its cover. To accelerate drying, the adhesive layer can be treated with hot air from a hair dryer and only then connect the parts together.

The composition of polyurethane adhesives includes organic solvents, so they are harmful to the body. When working, you need to provide good ventilation and wear a respirator. Contact with the skin means that it needs to be washed immediately with soap and water, otherwise irritation may occur. Glue items is only in rubber gloves.

to contents ↑Than to dilute and wash glue - means

If the glue has thickened, it can be slightly diluted with alcohol. It is important to introduce only a small amount of solvent, otherwise the product will be spoiled. Also on sale there are special solvents for polyurethane, or "viscosity optimizers", which are based on methyl ethyl ketone, acetone, ethyl acetate. Toluene can also be used, but the glue line will seriously increase in volume. To improve adhesion and heat resistance, it is permissible to introduce Desmodur activator in the amount of 7% of the total mass.

How to dissolve glue that has dried on tools? The spatula and other devices must be cleaned immediately before the substance has frozen. Otherwise, a rag moistened with acetone is used, and all dried drops are wiped with a liquid. Dissolved glue is removed mechanically.

to contents ↑Solidification time

The exact cure time depends on the type of adhesive, its composition, and a set of additional components.Typically, the initial cure lasts 20-60 minutes, it is for this period that a strong fixation of the parts is required. It is important that when pressing surfaces evenly, tightly adjoin each other. Full hardening of the compounds lasts a day, but for some adhesives it is 2 days. When exposed to hot air, polymerization ends after 4 hours.

to contents ↑Storage Features

In a closed container, the product is stored for 12-24 months at a temperature of + 10 ... + 30 degrees, the exact expiration date is indicated on the package. The container should be away from sources of heat, fire, sunlight. After opening the bottle, the adhesive based on polyurethane is stored for no more than 6 months, it is advisable to use the product as soon as possible. When air and moisture get in, the glue thickens or hardens, so the cork is twisted as tight as possible. Bottles, banks, tubes should always be upright.

to contents ↑Adhesive Manufacturers

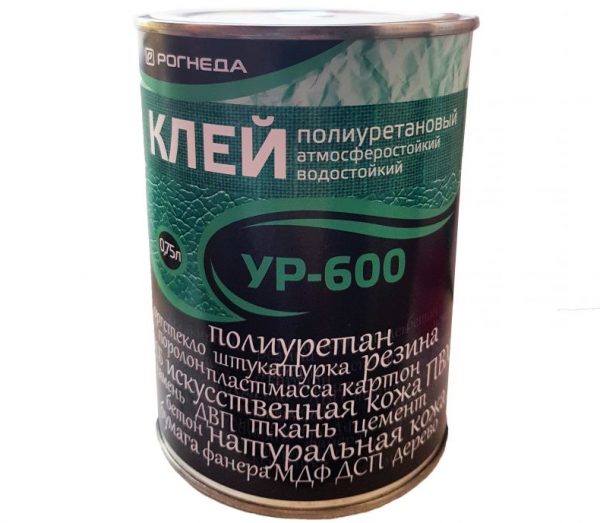

A large number of adhesives based on polyurethane are sold in stores. On the market, such products are provided by domestic and foreign manufacturers. Here are the most popular brands:

- Anles. The company's assortment includes about 10 polyurethane adhesives for industrial and domestic use. Respect users deserve adhesives "ADV", "Vilad", "Polyurethane", PVC Fix and others. All of them are used for gluing PVC, rubber products, polyurethane, thermoplastics, leather, glass, metal.

- "Titanium". Under this brand, several glues in cylinders intended for professional and home use are produced. “Universal” foam adhesive is especially known - a one-component composition for exterior and interior use, quick-drying, and highly fire resistant. Another good composition is Bonolit's Heat Formula. This glue is so strong that it is used for masonry blocks, the construction of external and internal walls, as well as partitions. It serves as an alternative to conventional cement mortars.

- Desmokol. It is widely used in shoe factories, reliably holds rubber and polymeric materials together. Available in small tubes, cans and even barrels of 200 liters.

- Kenda Farben. The company presents on the market a very high-quality polyurethane composition SAR 306, which has high heat resistance. It is used for bonding soles made of PU, TEP, various rubber products. Adding a special hardener increases the adhesion of other hard-to-stick materials.

- Sika. This Swiss brand produces a whole line of products based on polyurethane. Sikaflex polyurethane sealant is especially known for its high tensile strength, resistance to moisture, chemicals and physical impact.

- Inov. The cold-cured polyurethane binder of this brand from China is used for laying seamless coatings, the production of rubber plates, rubber crumb, rolls.

- Henkel. Line Tools Ceresit is a high-quality adhesive for tiles and other materials. The most famous polyurethane adhesive is Ceresit CT 84 - a tool for fixing window sills, filling gaps between polystyrene foam slabs, aerated concrete blocks, for attaching thermal insulation. Also on sale is glue Crystal Moment from "Henkel" - a transparent polyurethane gel for all types of materials except Teflon and polyethylene.

- Polynor. Polynor Stik glue is a one-component composition for fixing extruded polystyrene foam, aerated concrete, panels, mineral wool. It can be used for sealing joints and open areas, for fastening decorative elements.

- Soudal. Soudal brand produces Soudabond Easy polyurethane adhesive - a professional composition in containers for attaching mineral wool, cork, gypsum board, glass wool, foam blocks and fiber cement boards.

- "Lighthouse".Super NN glue of this manufacturer is intended for banner fabric, leather, laminate and parquet, all types of plastic, polyurethane, as well as rigid PVC and ABS. Before use, be sure to clean the base with Cosmofen solvents.

Polyurethane-based adhesives are also produced by Neomir, Rastro, Cleon, Adesiy, Bostik, Duayen and others. The funds have different prices and volumes, but, for the most part, are of good quality. You can buy excellent polyurethane adhesive in any hardware and hardware store.