In radio engineering, electronics, a gluing technique is widely used. Conventional adhesives are not suitable for parts that provide heat dissipation. For this purpose, special heat-conducting glue is used for radiators and a number of other elements.

- Scope and features

- Popular brands

- Heat-conducting adhesive "Radial"

- Alsil 5

- Gd9980

- Features of the use of heat-conducting glue

- Gluing the heatsink to the chip

- Glue making

Scope and features

This is a special material that is used for gluing LEDs, radiators, microcircuits. In appearance, the glue is a mass of white, with a uniform consistency. This adhesive composition should be distinguished from thermal paste: it is used where the product design does not allow the use of paste or mechanical fastening. The product is sold in tubes with a thin nose, it is very convenient to use.

The principle of operation of the glue is that it removes excess air between the bonded surfaces. After gluing, a heat-removing effect is provided, overheating of the parts during installation will be excluded. Deformation of elements due to overheating also will not happen. A distinctive property is the safety of the material, it does not contain toxic components. Even when heated, does not emit poisons, can be widely used at home.

to contents ↑Popular brands

The choice of thermal adhesives in stores is small. Literally several means are implemented, which it is recommended to glue products and microcircuits that are exposed to heat.

Heat-conducting adhesive "Radial"

Thermal conductive glue "Radial" - the most famous composition among analogues. It is sold in convenient packaging that allows you to use it several times. After opening, you can maintain tightness. The composition is not oxidized on silver, steel, aluminum. It can be operated at extreme temperatures - from -60 to +300 degrees. The main properties of the material:

- optimal viscosity;

- resistance to UV radiation and high humidity;

- excellent adhesion to any surface, especially to metal, plastic, glass, ceramics;

- thermal conductivity - 0.7-0.8 W / m * K;

- tensile strength - 2.3 MPa;

- high water resistance.

Alsil 5

This tool can also reliably glue parts, it provides good heat dissipation and does not allow the product to overheat. Most often it is used on computer memory cards, although it can also be used on radiators and LEDs. "Alsil 5" (Alsil 5) is economical, as it can be applied in a thin layer. Ease of use leaves no doubt - the glue is realized in the form of a syringe with a thin nose. Before buying, it is important to check the expiration date - old products can dry out.

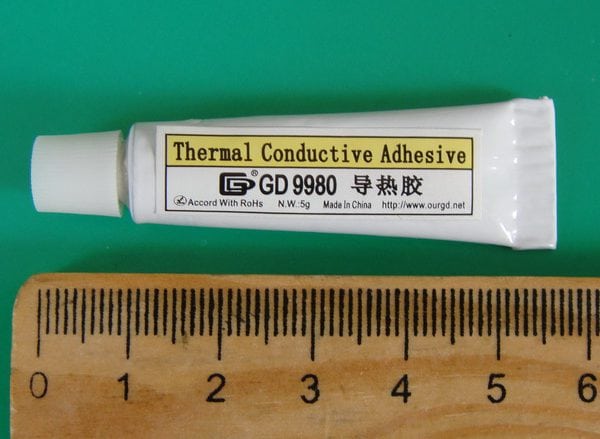

to contents ↑Gd9980

The heat-conducting adhesive GD9980 is designed to displace air between the surface of the chip and the base of the radiator. His ability to conduct heat is less than that of Radial glue, but he can firmly adhere parts to the processor, attach radiators to the motherboard, video chip, RAM.

The color of the product is white, the weight of the bottle is 5 g, setting takes place in 3-5 minutes. How to peel off such funds? Acetone or another solvent may be used to remove the formulations.

to contents ↑Features of the use of heat-conducting glue

For a quality result, it is important to carefully prepare the surfaces. They must be cleaned of dust and other impurities, then degreased. For this purpose, use acetone, alcohol, less often gasoline. Filling material (glue) is distributed on the basis, making sure that about 1 ml of the product falls on a square centimeter of parts. Then the products are pressed, make circular movements so that the glue is evenly distributed. They need to be pressed for 3-4 minutes, and put into operation in a day.

to contents ↑Gluing the heatsink to the chip

The heatsink is connected to the chip (microcircuit) in the same way as described above. How to stick a chip? For pouring, choose any glue from the listed. The only feature is the gluing time: it is worthwhile to securely press the parts for 10-15 minutes, after removing the load. You can operate the radiator after 24 hours.

to contents ↑Glue making

Adhesive for radiators can be prepared with your own hands. Glue recipes can come in handy if there was no money at the right time or if it is not on sale in the radio store. Here is the most famous recipe for “glycerin cement”:

- take glycerin, heat it in any way to a temperature of +200 degrees (this will remove all water from the liquid);

- separately heat lead oxide to 300 degrees;

- measure 100 g of lead oxide with 25 ml of glycerol, combine both components, but first they should be cooled to room temperature;

- mix quickly, the viability of such an adhesive is up to 15-20 minutes, not more;

- by consistency, the finished product resembles gruel, batter;

- the material can withstand temperatures up to +250 degrees (after complete curing).

There is another recipe for heat dissipation glue. It is made on the basis of store heat-conducting paste, which is not suitable in every case, since it is very thick. Acetone is added to it in small portions, mixed thoroughly. The finished mass should resemble sour cream. Then 1 part is injected into 3 parts of the paste epoxy adhesive. A larger amount of epoxy cannot be added - as its volume increases, thermal conductivity decreases.

Adhesives with thermally conductive properties are indispensable in the repair of computers and radio equipment. They have great tensile strength, therefore, they help to attach any elements in a lateral and vertical position. With strict observance of the instructions, the connected unit will serve for a long time.