To fasten different parts, it is far from always necessary to use welding or nails, screws. In building stores there is epoxy glue, and this tool provides a very reliable adhesion of surfaces. The scope of use of the material is wide, it is bought for domestic needs and for creativity, used in production.

- The purpose of epoxy glue

- Advantages and disadvantages

- Composition and properties

- The difference between epoxy glue and resin

- Types and characteristics of glue

- Common brands

- Epoxy adhesive instructions

- Glue preparation

- Glue for concrete

- Metal Remedy

- Bonding plastic

- Temperature mode

- Drying time

- Security measures

The purpose of epoxy glue

What is epoxy glue, every master knows, builder-installer, technical worker. It is an adhesive with an epoxy resin (epoxy) in the composition, a polymeric material with excellent adhesion to various surfaces. Even with the advent of more modern adhesives on the construction market, epoxy does not lose popularity.

Most often, the adhesive composition is used in construction. It is ideal for concrete and for metal, wood and glass. Like cold welding, an epoxy-based material is needed for bonding plastics (polypropylene, polycarbonate and many other types of plastic). The versatility of the adhesive makes it suitable for working with rubber and ceramics; it is intended for stone (granite, marble, artificial materials). Epoxy resin is used for filling floors, it is part of primers, putties, mixtures for tiles, mosaics.

The product is widely used in everyday life. Due to its good adhesion and suitability for plastic, they can glue various products: equipment, electronics, computer parts. The tool is useful in the repair of a heating battery, dishes that are not in contact with food, for wood and wood products, jewelry and leather jewelry. In the automotive industry and auto repair, epoxy glue is suitable for the bumper in the presence of cracks, chips, for sealing the gas tank of the car and the radiator for minor defects. They repair boats and boats with epoxy glue, fill in various technological units, and fix solar panels.

to contents ↑Advantages and disadvantages

Epoxy has a number of positive characteristics, so it continues to lead among analogues. Here are the benefits of glue:

- elastic seam - the presence of a small mobility of the adhesive joint will prevent the appearance of cracks and will not allow destruction;

- the ability to withstand temperature fluctuations - the product is heat-resistant, you can use the finished product at temperatures up to +250 degrees (individual adhesives are even more high-temperature);

- no harm from low temperatures - the adhesive joint is frost-resistant, does not lose strength characteristics even at -30 degrees, this allows the material to be used for outdoor work;

- moisture resistance - glue with epoxy is waterproof, during operation does not respond to the action of water, water vapor;

- suitability for gluing most known materials - the glue is really universal, suitable for almost any surface;

- short drying time - after application, the parts quickly become a single whole, and after the final polymerization it is practically impossible to peel them off.

Despite the high quality, heavy-duty composition of the product, it has several disadvantages. Here they are:

- you can not use the mass for gluing objects in contact with food, this will harm the body, can cause poisoning;

- the instruction prohibits gluing with a tool silicone, polyethylene, teflon, these materials will be destroyed by the action of resin, the adhesive can even partially dissolve them;

- the glue has a too high hardening speed, and the novice master may not have time to cope with the task;

- wiping the product off the surface is very problematic, it will have to be cleaned immediately, before hardening;

- in contact with skin there is a risk of developing allergies or getting burns, you only need to work with gloves on.

Composition and properties

Epoxy adhesives from different manufacturers may contain different components, but the basic composition is always the same, it complies with GOST, the attached certificates. Strictly binding are the two main substances in the composition:

- epoxy itself;

- liquid or paste hardener.

Polyamines, carboxylic acids, aminoamides are used as curing agents. One-component adhesives always contain solvents (acetone, xylene, alcohols), which, prior to contact with air and evaporation, prevent solidification of the mass. How modifying additives and fillers for glue can act:

- synthetic rubber;

- formaldehyde resin;

- fiberglass;

- clay, chalk;

- aluminium oxide;

- powders of vanadium, nickel, zinc;

- organosilicon resins.

The glue also includes plasticizers, which give it plasticity. Thanks to them, the mixture hardens and does not crumble, remains elastic. The percentage of bulk and different fillers varies widely - from 5 to 50%.

All of the above binding components provide the epoxy adhesive with the desired properties:

- optimal density;

- seam strength;

- high cure rate;

- resistance to oils, gasoline, water, atmospheric factors;

- resistance to cracks, shrinkage.

It is also worth noting that the glue does not conduct current - it is an insulator, so it is often used to isolate electricity.

to contents ↑The difference between epoxy glue and resin

The main difference between these materials is that the epoxy is a polymer with a hardener, and the adhesive is a mass with a complex composition. The latter includes various modifiers and fillers. Also, differences should be noted on the following grounds:

- solidification time: the adhesive begins to harden after the time specified by the manufacturer, it is impossible to influence the process, and the polymerisation of the resin may slow down or accelerate under the influence of physical factors;

- color: usually the shade of the resin is transparent and remains so for a long time, and the glue at first looks similar, but then turns yellow;

- purpose: for what resin is used, it is difficult to list (pouring, manufacturing of many types of plastic, putties, coatings, figures), with glue, you can only repair different products.

Types and characteristics of glue

By the number of bottles included in the package, the glue is of the following types:

- One component. This is a mixture of epoxy with solvents and plasticizers, ready to use. It begins to harden after opening the sealed package. Typically, such adhesives perform a small amount of work, they can seal small defects, seal the seams, close the gaps. Tools are widely used in everyday life, needlework.

- Two-component. It is realized in packaging in the form of two containers. In one there is an epoxy in the form of paste, plasticine, in the other - a hardener. They need to be mixed in a certain proportion, quickly applied as directed. Most epoxy adhesives are two-component, they can be glued to almost any item.

The consistency of adhesives are liquid and in the form of a plastic, thick mass. Liquid materials are sold in tubes; they do not require dilution.Plasticine mass is recommended to repair chips, pits, and other defects. Before use, it must be kneading in the hands, mix.

to contents ↑According to the method of curing, the materials are classified into those requiring heat treatment and not requiring it. The former is heated before the introduction of the hardener, the latter must be kept at room temperature.

Common brands

On sale you can find a huge variety of epoxy adhesives, among them there are imported and domestic brands:

- "Contact". Well suited for rooms with high humidity, suitable for sealing pipes, bathtubs, toilets.

- "Moment" from Henkel. Implemented in every hardware store, the most popular. It is packaged in different packages - weighing from 5 g, convenient and reliable.

- "Super-Grip" epoxy equal component. The composition contains mineral fillers, which increases the bonding strength. It has no restrictions on the processed materials.

- "Bison". A two-component colorless gel, used to fill voids, cracks, chips, helps restore the shape of the product.

- "Class". An analogue of the previous composition. Ideal for use on metal and various alloys, it helps to repair cars, sinks, pipes.

- "Second". The fast bonding effect is a distinctive feature of the product, it completely hardens in 3 minutes.

- "Novocolor adhesive epoxy station wagon." It is characterized by low shrinkage and high adhesion to various substrates, it allows to seal products with large cracks and chips.

- Metal Bond. 5-minute glue for all types of metal can also stick metal surfaces to wood, plastic, and other materials.

- Compound K-153. The tool is black, used for metal structures exposed to water, petrochemicals.

- Ultima ("Ultima"). A two-component tool used to connect most of the known materials, including decorative and facing ones. Suitable for car repair, boats, household appliances, plumbing.

- Poxipol (Poxipol). Quick-drying composition, hardens 10 minutes after preparation. You need to work with him very quickly.

- EAF. Ideal for all surfaces - from metal to glass. Optimum in the ratio "price-quality".

- Epoxy steel. Great for any type of metal, it is often referred to the category of auto chemical goods and is recommended for car repairs.

- DoneDeal "Epoxy Adhesive" in the syringe. A two-component adhesive that provides a completely impervious to water connection.

- BisonEpoxy 5 min. It features fast polymerization, highly reliable adhesion of surfaces.

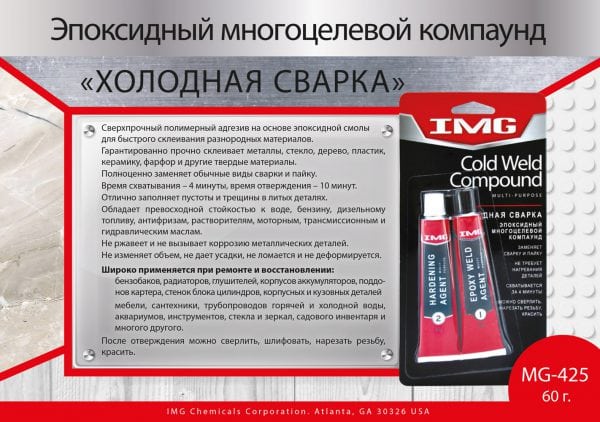

- "Abro" (Abro). The glue of this article is available in two colors - white, black, is a "cold welding" for all types of surfaces.

- Novol Plus 710. This is a repair kit consisting of resin, hardener, glass mat (fiberglass). Suitable if the product to be bonded has significant defects, cracks.

- Uhu. It is used to connect different types of plastic and metals, it can act as a means for pouring.

- "Defense - EC." Chemical resistant epoxy adhesive, sold in large containers (10 kg each), used mainly in production.

- Epoxy Titan. Material of increased strength, resistant to shock loads, uniform. Packed in blisters for 20 and 200 ml, in buckets of 2 liters.

Epoxy adhesive instructions

All work can be divided into three main stages - surface preparation, mixing of the adhesive composition, direct gluing of products. Any instruction for use means that a thing can be repaired correctly and reliably only with good cleaning.

All traces of dirt, dust should be washed off, fat should be removed by wiping with degreasers. Before sticking the product, it must be thoroughly dried. Only a dry object can be coated with epoxy, because it does not tolerate even a drop of water, it immediately deteriorates. To improve adhesion, smooth products should be wiped with sandpaper.

There are a number of tips when gluing different surfaces:

- too cold a bottle, a tube with resin is better to warm up before use (this can be done in a bowl with hot water, placing the product there before opening);

- if after the first use the glue is to be stored, it is placed in the refrigerator, as much air as possible is previously removed;

- it is necessary to strictly observe the proportions of mixing the resin and hardener, which are indicated in the manufacturer's description, otherwise the result will be unpredictable;

- sawdust, shavings, chalk can be added to the finished glue - these fillers will help to better repair large cracks (filler norms - 10-20%).

to contents ↑

Glue preparation

How to dilute epoxy glue? The correct method of preparation is indicated in the instructions for the specific product, there are also proportions of resin and hardener. Most often it is recommended to mix 10 parts of epoxy and 1 part of hardener, but in some cases the ratio is different - 5: 1.

It is necessary to breed material in a separate bowl, preferably in a disposable one. It is necessary to prepare a container in advance, which can then be discarded. First, you need to squeeze the right amount of epoxy, then dilute it with a hardener. The liquid must be added slowly, otherwise a violent thermal reaction will begin in the container and the resin may deteriorate. Next, carefully stir the product by hand until the mass becomes completely homogeneous. To do this, use a wooden spatula, stick.

The glue is ready to use, they can glue any objects, apply for molding, moisten paper, fiberglass, gauze. The impregnated material is wrapped around the product or a piece is glued to seal the defect.

to contents ↑Glue for concrete

Many epoxy adhesives are suitable for sticking different materials to concrete surfaces. All of them are two-component, consist of resin and hardener. An example is Eporip epoxy glue, which in finished form is a thixotropic paste. The latter is applied to horizontal and vertical concrete substrates with a brush.

The compositions are used for bonding metal with concrete, joining precast elements from reinforced concrete. They also create an adhesive layer between old and new concrete, fill the cracks. It is forbidden to apply glue on a wet surface, nor can a fresh layer of concrete be laid on glue that has just set.

to contents ↑Metal Remedy

How to glue metal products using epoxy adhesives? The technology is standard - you need to mix the components of the product, apply them to a skim dry, clean surface. Glue “Moment Super Epoxy Metal” is perfect, it is used on steel, copper, aluminum, alloys. The finished adhesive joint can withstand temperatures up to +250 degrees, so the products can be used in appropriate conditions.

to contents ↑Bonding plastic

Using epoxy, almost all types of plastic are glued, but this material is divided into the following types of adhesion:

- easily glued (preparation is not required) - polyacrylate, ABS, polycarbonate;

- conditionally easily bonded (need a little preparation) - polystyrene, polyesters;

- hardly glued (serious preparation is necessary) - polypropylene, polyformaldehyde.

At home, you can fasten the plastic of the first two groups, while the third type of material at home is better not to use. Any epoxy adhesive is suitable for plastic, an EAF is considered an ideal option. Conventionally bonded materials are treated with sandpaper. Plastic degreasing is carried out only with ethyl alcohol. Acetone, solvents must not be used! After applying the glue, fix the parts for 1-1.5 hours, then dry it within the time specified in the instructions.

to contents ↑Temperature mode

Most adhesives perfectly tolerate heating up to + 150 ... 180 degrees, the strength of the seam from this does not decrease. Some brands can withstand up to +250 degrees, others even suffer a short-term exposure of +400 degrees.

The temperature at which the glue hardens is, of course, different. Usually enough room temperature is 20-23 degrees. Some products freeze well at + 10 ... + 15, but not many. Typically, a decrease in temperature slows down the polymerization reaction, an increase - to accelerate the hardening of the resin.

to contents ↑Drying time

How long does the epoxy adhesive dry? As a rule, complete polymerization is achieved in 24 hours, before this time the product cannot be operated. But small items that will not carry the load can be used after 12 hours (for example, brooches). Initial hardening lasts 30-60 minutes, cold welding hardens in 5-20 minutes. It is necessary to carefully read the instructions before work in order to have time to apply the mass on time - otherwise it will be spoiled.

to contents ↑How to remove an extra tool? To remove glue residue, you need to act immediately, until the composition hardens. A cloth is used, a piece of bandage, which removes the crawled mass. In the future, stains can only be removed mechanically.

Security measures

Work with glue should be carried out only with gloves, a respirator, tight clothing. The room provides forced ventilation, because the glue vapor is harmful to the body. If the product gets on the skin, it is washed with soap and dried thoroughly. Dishes in which glue was diluted must be discarded - it is impossible to cook in it, as well as to consume food. Large-scale work is best done in the fresh air so as not to harm yourself and loved ones.