Finishing work in the bathroom, in the kitchen, in other rooms and outside the house is often done using ceramic tiles. For its fastening, a special tile adhesive is used - a material bred from a dry mixture, which has high strength and reliability.

- Glue application

- Description and Specifications

- Preparation of glue solution

- Foundation preparation

- Sequence of work with glue EC 3000

- Precautionary measures

A striking representative of this group of building materials is glue for tiles EC 3000. It is suitable for a variety of works, attractive at a price, therefore highly appreciated by professionals.

Glue application

High-strength glue EC 3000 belongs to the same “family” of wall covering products as EC 2000 glue, but it has improved technical characteristics. Operational properties allow the use of this adhesive for exterior and interior use, it is also suitable for various rooms with high humidity.

Worth to know! The main purpose of the adhesive is to lay mosaics and ceramic tiles. The tool is also suitable for natural, artificial stone, granite.

Bases with which the adhesive shows sufficient adhesion:

- concrete;

- drywall;

- brick;

- plaster;

- aerated concrete.

You can apply the product for the subsequent sticker of the tile on both vertical and horizontal surfaces. It is widely used for decorating bathrooms, floors and walls in the kitchen, lining socles, pools. The glue is ideal for stone slabs with moderate water absorption (up to 1%), medium and small tiles. It can also be used in the process of installing a warm floor, for filling tile joints, leveling the bases with small differences in height.

to contents ↑Description and Specifications

This material is universal, because the type of substrate has almost no effect on the technical properties and quality of gluing. EC 3000 is available in different containers - usually on sale are banks with a volume of 5-25 kilograms. Shelf life in tightly closed containers (without damaging the factory packaging) is six months from the date of manufacture.

Description of the main technical parameters:

- the shade of the finished solution is gray;

- the pot life of the solution is 4 hours;

- work time with tiles - 20 minutes;

- time for adjusting the position of the tile - 15 minutes;

- adhesion value - 1 MPa;

- compressive strength - 15 MPa;

- frost resistance - from 35 cycles;

- ambient temperature during operation - from -5 to +30;

- operating temperature without damage to the coating - from -50 to +70 degrees.

Due to the high degree of adhesion, the product is also suitable for vertical surfaces. Even heavy tiles will not slip, change position in the future, it can be stacked from top to bottom, if required by technology.

Important! EC 3000 glue is harmless, its composition is environmentally friendly.

Consumption per 1 m2 is low. For the calculation, you need to know the quadrature of the treated area, as well as the degree of moisture absorption of the base (for very porous surfaces it is worth increasing the rate of glue). Typically, no more than 2.5-3 kg of glue is used per square meter of surface, the layer thickness being 5 mm.

to contents ↑Preparation of glue solution

To make the solution, you need to prepare clean, cool water. 5.75-6.75 liters of liquid is enough for a bag of 25 kg, that is, the flow rate will be 0.23-0.27 liters per kilogram of dry mix.Adjustments to the norm are possible, but at the output the finished mass should be uniform, thick, like sour cream. The order of preparation of the EC 3000 solution:

- Accurately measure a smaller volume (indicated on the packaging) of water.

- Pour water into a mixing bowl.

- Pour in glue powder.

- Use a construction mixer, drill with a special nozzle to mix (manually mix the mass so that there are no lumps, it will not work).

- Wait 10 minutes.

- Mix again, if necessary, add more water.

- Get to work.

Foundation preparation

The wall, floor or other foundation on which the EC 3000 will be applied must be carefully prepared. It is cleaned of dirt, dust, grease, old coatings are removed: paints and varnishes, putty. If you leave such contaminants, the adhesion quality of the adhesive will decrease. In the presence of pits, depressions more than 5 mm in depth, any suitable plaster should be diluted and the irregularities should be repaired. It is necessary to start further work after the wall has completely dried up.

Before gluing the tiles, the peeled base should be primed. With strong surface absorption, it is recommended to use special primers. EKANTISEPTIC / EKG300DEEP primer is good. The primer also needs time to dry.

to contents ↑Sequence of work with glue EC 3000

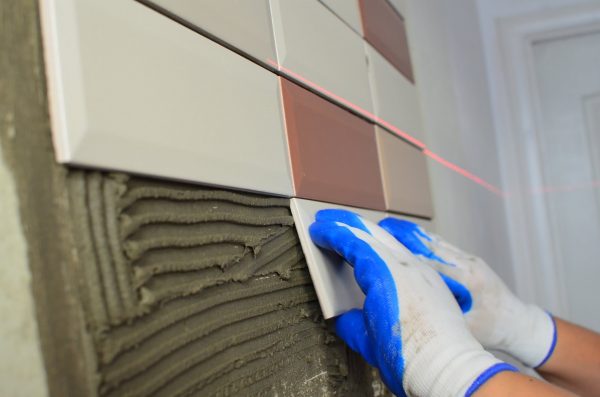

The use of this glue does not imply a preliminary soaking of ceramic tiles or other materials. That is, when gluing, the tile must be dry! Glue in the solution is applied in one direction using a notched trowel. Immediately lubricate several tiles, then alternately carefully press them to the base.

It's important to know! Since the product does not retain adhesive properties for long, there is little time for adjustment - do not immediately apply it to too large areas of the tile.

After applying the plates according to pre-made markings, their location is changed until the ideal result is achieved, acting quickly. At the end of the work, the tile joints are cleaned. They need to be filled only after the glue dries under the tile itself. The adhesive composition hardens in 16-24 hours, but the time of full strength is much longer - 72 hours. Immediately after completing work, you need to clean the tool well.

to contents ↑

Precautionary measures

Cement is present in the adhesive - this must be taken into account when working with dry powder. In order to avoid getting it into the respiratory system, you need to use a respirator. It is advisable to wear safety glasses on the eyes. When mixed with water, an alkaline reaction develops and gloves should be worn to protect the skin of the hands from accidental contact with glue. Eyes when a powder or solution penetrates, rinse well with water.