For laying tiles, it is necessary to use specialized compounds - tile adhesives. Litokol company produces high-quality products under the Litoflex brand, which have excellent technical characteristics. Glue Litokol allows you to work with different types of tiles, although there are some restrictions on the application.

- Material Features

- Specifications

- Material advantages

- Scope of application

- Foundation preparation

- Glue preparation and application features

- Adhesive Recommendations

Material Features

Tile adhesive Litoklex Litoflex K80 is a dry cement mixture containing various improvers, artificial resins, chemical additives to improve adhesion. These substances are designed to optimize performance. This tile adhesive has excellent elasticity, which compensates for the tension between the individual elements of the masonry, between the tile and the base, even with temperature changes.

Clay Litokol is often chosen by professionals, builders, as it is very convenient to use. Litoflex K80 is technological, economical in consumption, environmentally friendly, does not contain any harmful additives. Thanks to the quick setting with glue, you can finish all work with tiles without delay. Due to the heat resistance, the glue can very well be used in the installation of a warm floor.

to contents ↑Specifications

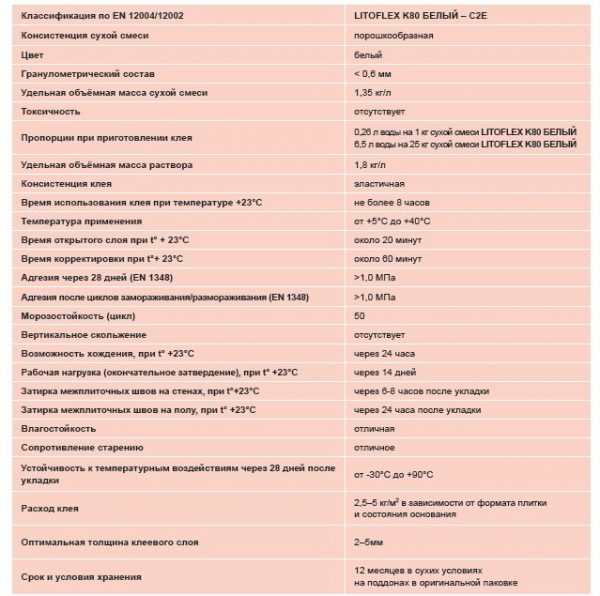

The composition of the glue includes white dry cement, as well as the necessary fillers. The total color of the dry mass is grayish. The main technical parameters of the product:

- the consistency of the finished glue is pasty;

- temperature of use of the mixture: + 5 ... + 40 degrees;

- operating temperature of the adhesive joint: -30 ... + 90 degrees;

- application time of the diluted mass - 8 hours;

- time for adjusting the position of tiles - 60 minutes;

- specific gravity - 1.35 kg / l;

- adhesion - 1 N / sq. mm;

- frost resistance - not less than 50 cycles;

- moisture resistance - high;

- resistance to aging is high;

- glue layer thickness - 2-5 mm;

- glue consumption - 2.5-6 kg / sq. m depending on the size of the plates and trowel teeth.

After applying the tile adhesive, Litokol dries within 24 hours, but it is recommended to give it a serious load no earlier than 14 days, when the final hardening occurs. Glue does not allow vertical sliding of the tiles, so it is used for wall decoration. Grouting the joints on the walls after gluing the tiles can be done in 6-8 hours, on the floor - only after a day.

to contents ↑Material advantages

A huge plus is the rapid drying of the product (day), while for analogues this period can reach 2 days. The life cycle of the solution is also quite high (8 hours), as well as the time to correct the position of improperly laid tiles. The advantage is the cost-effectiveness of the product, because its consumption due to the small thickness of the adhesive joint is small.

Other advantages of glue:

- obstacle to sliding tiles;

- work with various materials - porcelain stoneware, tiles, mosaics;

- non-toxicity, the ability to apply glue even in child care facilities;

- high adhesion, allowing to equip tiled coatings in places with significant load, high traffic;

- the absence of damage to adhesive joints when exposed to adverse factors (temperature changes, the influence of UV rays);

- moisture resistance - glue can be used in rooms with high humidity (bathtubs, showers, basements, medical facilities);

- frost resistance - the product is suitable for laying tiles on the street, in unheated rooms;

- reasonable price - Litokol costs about 220 rubles / 5 kg of dry mix.

Scope of application

In addition to all types of ceramic tiles, porcelain tiles, you can use Litokol for laying facade clinker tiles, as well as natural and artificial stone. Thanks to this, K80 is considered a universal glue and is very popular in construction and repair. It can be applied to fixed substrates and surfaces, which in the future can be deformed, shifted.

Clay Litokol - one of the few that allows you to apply the technology of "tile to tile". Most often, glue is used for wall and floor cladding, outdoor steps and terraces, facades, balconies. Also, Litokol is suitable for arranging warm floors.

Here are the bases on which you can lay tiles with glue:

- brick, aerated concrete, concrete, including cellular;

- various types of screeds and plasters, which include cement, including heated;

- drywall, gypsum fiber;

- gypsum bases, plaster panels;

- old tile;

- any bases with a waterproofing layer.

According to the manufacturer's recommendations, Lithoflex can not be used for laying porcelain tiles more than 40 * 40 cm in size. Also, it is not used for surface finishing with large facade tiles - for this purpose it is better to buy other products of the Litokol brand (for example, X11). If the base can deform sharply, it is worth using LATEXKOL-m glue, which additionally contains latex to increase elasticity. When you have to finish the pools, it is better to purchase a specialized product with enhanced moisture resistance of Lithoplus K 55, and for large-format plates - Superflex K 77.

to contents ↑Foundation preparation

Before work, you need to make sure that the base is smooth, without swings and waves. It is necessary to carefully check the surface level, the maximum allowable difference is 3 mm. If it is larger, first you need to plaster the walls with any suitable mixture (for example, Lithogypsum, Lithoplan Rapid). For the floor, pouring with a self-leveling mass from the Litoliv series is suitable. After such work, it is allowed to use the tile only after 14-28 days when the humidity reaches not more than 3%. Concrete substrates are aged for at least 6 months.

Just before finishing, you need:

- make sure that all areas are strong, securely fastened;

- warm and cool the underfloor heating thoroughly;

- treat gypsum, anhydride substrates with primers with the function of reducing water absorption (for porous substrates, 2-3 primers should be carried out);

- dry floors, walls after applying a primer;

- clean the surface of grease, dirt, paint, other substances, otherwise the adhesion level will decrease;

- grind, then remove dust from the base.

Glue preparation and application features

Masters prefer to purchase large packages of Litokol containing 25 kg of dry weight. To dilute the entire package, you need to take 6-6.5 liters of water. The temperature of the liquid should not exceed -20 degrees, but also not less than +15 degrees. Glue is prepared only by pouring dry powder into water. If you change the mixing order, this will lead to lumps.

It is better to stir the glue not manually, but with a construction mixer, a drill with a nozzle. Beat the glue until it gains an even structure without lumps. For ripening, they withstand a mass of 10 minutes, covering it from above. After again mix well Litokol. Further, it is considered ready for use.

To work with tiles and glue, you need to buy two spatulas (flat and comb) or one tool with two different sides. The size of the tooth is selected on the tile - the larger it is, the larger the size of the tooth.

Recommendations for work are as follows:

- distribute glue on the base with a smooth spatula;

- apply glue to the tile with a notched trowel;

- immediately cover the tile, which is planned to be glued for 15 minutes;

- in some cases (the need to improve adhesion, improve the quality of work), it is necessary to apply the product both on the base and on the back side of the elements, otherwise applying only to the tile is enough;

- within an hour, you can change the position of individual elements, this will not affect the quality of the masonry;

- do not forget to make seams between the elements, their sizes are determined by the dimensions of the main material;

- between the tiles you need to insert the appropriate crosses, then the seams will be even.

With a material size of less than 10 cm, seams of 2-3 mm are enough, for 20-cm elements - up to 4 mm. Tiles up to 30 cm in size will require 4-5 mm joints, more than 30 cm - up to 5-10 mm.

to contents ↑Adhesive Recommendations

An increased amount of glue must be applied to large-format material, pool lining, when installing a warm floor. In standard cases, 60% of the boards are coated with glue for internal work and 100% for external work. Other tips for the master:

- when facing pools it is important to carry out full waterproofing first;

- after installing a warm floor with tiles, you can work only after 14 days;

- it is impossible to soak ceramic elements before work, they must be well dried, clean;

- in hot weather, the drying time of the glue, the period of preservation of the possibility of adjustment is reduced, and a dense film forms on the surface of the finished solution, which must be periodically broken;

- if the “tile to tile” technology is used, it is important to wash the old surface with a solution of caustic soda (a kilogram of soda per 9 liters of water) in order to degrease the base well;

- you can not independently enter cement, gypsum, other substances into the glue, it is fully equipped in composition;

- you can dilute the mixture only with clean water;

- it is undesirable to carry out laying with too high humidity, the presence of drafts, on the street it is important to wait for the onset of clear, warm weather without wind.

To close the joints as the glue dries, it is better to choose Litokol grouts, which guarantees perfect compatibility and a long service life.