Linoleum - PVC roll material for decorative flooring. Professionals recommend buying it in accordance with the size of the room - to adjust the width so that there is no docking. But this option is not always possible, often it is necessary to carry out laying with joints.

- Gluing the joints of linoleum - tips

- Double sided tape

- Cold welding

- Hot welding

- Glue gun

- Invoice nut

- Soldering iron application

- Bonding with mastic

- Adhesive compounds

- Dispersion adhesive

- Reaction glue

There are ways how to glue linoleum so that the seams are invisible. Following the recommendations, you can end up with the perfect flooring.

Gluing the joints of linoleum - tips

Docking seams cannot be dispensed with if linoleum is laid in offices or large rooms. You will also have to glue the end-to-end material cuts, if you had to buy a coating 1.5 meters wide, it always costs less. Gluing technologies are diverse, which is better to choose? Here are the selection rules:

- cold welding is considered a good way, it can be learned to do even at home - special skills, special equipment is not required;

- hot welding - a method that allows you to get high-quality gluing, but for its implementation it is worth inviting masters (requires professional skill);

- it is permissible to connect small-sized seams with double-sided tape;

- if the linoleum segment ends at the border of two rooms, the optimal choice is to install a nut.

Double sided tape

Joining joints with tape is the cheapest, fastest, but short-lived way. It is suitable as a temporary measure, but sticking together with your own hands is as simple as that. Adhesive tape is not suitable for felt-based coatings - it cannot be held on felt. Also, the disadvantages include low moisture resistance - if water gets into the tape when washing the floor, it will soon become unusable. In addition, the junction will stand out against the background.

Correctly glue the edges of linoleum need this:

- clean the floor from dirt, dust, it must be completely dry;

- if you need to glue the joints to the concrete floor, you can begin to work, in the presence of a porous base it must first be primed;

- parts of the canvas must be carefully joined so that they do not overlap each other, if necessary, trim with an office knife;

- bend the edge of each cut, stick adhesive tape to the floor with one side;

- remove the top layer from the tape, cover with linoleum, press firmly;

- roll the place of gluing with a roller (hard).

Cold welding

Despite the name, no welding machine is needed for this method. Installation technology involves the use of adhesive polymer mixtures, which are "related" to the composition of linoleum itself. Usually based on artificial rubbers or other materials. When gluing the base, it comes into contact with the tool, melting the edge. As a result, the glue will connect the edges so that they do not stand out. In the same way, you can glue a torn piece of the coating.

A huge advantage is the water resistance and durability of the joint. Cold welding used both in offices and at home. The following types of cold welding are produced:

- colorless glue for foamed linoleum;

- paste for felt material on a polyester substrate;

- dense structure for seams with gaps.

Glue supply is carried out by a special machine with a needle. Work is carried out strictly with gloves - the compositions are aggressive. For the same reason, the surface of the coating in the joints should be sealed with masking tape.

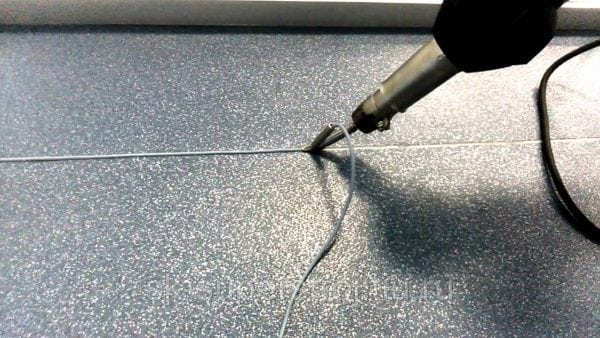

to contents ↑Hot welding

You can fasten the edges of the flooring in a professional way, it was called "hot welding". You can familiarize yourself with it on the video, but independent execution is not recommended!

For work, a special welding cord of the desired shade is used, of the tools - a building hair dryer and a milling machine. The cord is tucked into the hair dryer nozzle, heated very much, as a result of which the PVC melts. Then it can be glued to the joint. First, the machine needs to cut a groove up to 1 mm deep, up to 4 mm wide. After carrying out work with a special knife, excess material is removed, and after its cooling, fitting and smoothing are done.

This method allows you to get the highest quality and durable seam that will not protrude and stand out visually. There are cords of the right color for sale. The variety of shades is so great that there is a chance to choose the material for any linoleum.

to contents ↑Glue gun

Glue for joints can be applied to the seam using special equipment. There is a gun for hot gluing joints, which is sold in hardware stores. It must be connected to the network, pour glue, which will gradually heat up. Depending on the type of coating, you need the correct selection of adhesive compositions, they are as follows:

- to work with any new coatings;

- for sealing defects on old linoleum;

- for mounting polyester materials.

to contents ↑Before the start of the process, the floor and linoleum are cleaned of dirt and dried. Next, you need to pour the composition into the gun, warm it up. The nozzle must be directed directly to the place of the weld. The product that has come out from under the edges is removed until it hardens, after which it will be difficult to wipe it off.

Invoice nut

If the joint is in the middle of the interior doorway, a good option for securing it is the invoice door sills. The store should immediately pick up the product, combining with the main coating in color. The order of work is as follows:

- Cut the sills with a jigsaw, hacksaw to achieve the desired size (along the width of the doorway).

- Put the bar on the floor in the seam area, in the holes for fasteners make notes with a pencil.

- Remove the planks from the floor. Insert the drill into “6” into the drill, make holes according to the markings.

- Reattach the bar, fasten with dowels and screws.

Soldering iron application

Using a soldering iron will not work to fasten large seams. The soldering method can only be considered for joining small pieces or sealing defects. Small joints after using a soldering iron will not be evident, but significant spoils the entire aesthetics of the room. They turn out ugly, rude. There are other disadvantages of the method:

- fragility of the seam, its rapid destruction, if the coating will undergo severe friction;

- the inability to melt modern types of linoleum - only old material is suitable for this.

to contents ↑The technology is as follows: the soldering iron must be turned on, heated, and the edges of the coating melted. Next, connect them together, press. After complete cooling, cut off the tubercles and other protrusions. If the seam is too coarse, even before freezing it is necessary to go through it with a hard roller.

Bonding with mastic

You can glue the joints of linoleum using mastic, it is very in demand for floor repair. But we must remember that such tools include a number of additives that can be glued without the possibility of separation.It will not work to remove the coating without damaging it - it will begin to tear in pieces.

Work sequence:

- clean and primer the floor;

- joints of linoleum should be treated with a degreaser safe for PVC materials;

- after complete drying open the mastic, put it on the floor with a small spatula;

- press the edges of the coating, roll the seam with a roller - so its parts will be better connected to the base.

Within 24 hours, you can’t walk along the seam, but it is necessary to put a load on it. The complete immobility of this site is important.

to contents ↑Adhesive compounds

There are two main groups of adhesives that fix linoleum. These are dispersion and reaction compounds. Below they will be considered in more detail.

Dispersion adhesive

A distinctive feature of such compositions is the presence of an aqueous base, as well as acrylic or modified cellulose. Dispersion adhesives include the necessary fillers, giving the seam strength, elasticity. It is easy to apply glues even without work experience, while they will not cause harm even in the children's room, they are completely safe. Of the minuses, it is necessary to indicate low moisture resistance, the inability to operate or store at low temperatures. Typically, these adhesives are used in rooms with low or medium traffic.

In construction stores, the following types of funds are sold:

- bustilate - suitable for material on a foam base, on felt and pile, in the composition there are latex, chalk, carboxymethyl cellulose;

- humilax - is used for linoleum having a natural tissue substrate, based on rubber, latex;

- bituminous mastic - also suitable for material with a fabric base;

- acrylate glue - very thick, suitable for natural or synthetic fabric base, gives the most reliable seam;

- conductive adhesive - necessary in rooms where there is a lot of electronic equipment, provides an antistatic effect.

The layer of dispersion adhesives is usually up to 0.6 mm thick, it is laid with a spatula, then linoleum is applied to it.

to contents ↑Reaction glue

Such tools are used for cold welding of linoleum. Econ glue can be used as an example. They consist of aggressive chemical components that can dissolve part of the coating, so working with them requires extra care. Of the minuses - a pungent odor, a high price compared to dispersion adhesives, rapid ignition. These adhesives are not suitable for fabric-based coatings.

The pros include:

- resistance to moisture;

- long service life;

- very strong connection of the edges of linoleum.

There are several types of reaction adhesives. The former are used only for gluing a new coating onto a clean base. The second ones help to close up old defects, places of seams divergence. Still others include particularly strong additives, used mainly in offices. According to the description of the methods you can choose the right one and fix the linoleum with your own hands, efficiently and quickly!